Enameled Wires For Motor Rewinding

2024-05-30

One essential component in motor rewinding is the enameled wire, an indispensable element that ensures the motor's optimal performance. Electric motors play a vital role in our daily lives, powering countless devices and machinery.

Enameled wires, also known as magnet wires or winding wires, are copper or aluminum wires coated with a thin layer of enamel insulation. This insulating layer is typically made of polymers such as polyester, polyurethane, polyamide, or polyesterimide. These coatings provide excellent electrical insulation, enabling the wire to handle high voltages and currents without short-circuiting.

Benefits of Enameled Wires in Motor Rewinding:

Enhanced Efficiency: The low electrical resistance of copper or aluminum combined with the high-quality insulation of enameled wires results in reduced energy losses. This translates into enhanced motor efficiency, lower power consumption, and ultimately, cost savings in the long run.

Electrical Insulation: The primary purpose of the enamel coating is to insulate the copper or aluminum wire, preventing the flow of electric current between adjacent turns. This insulation ensures that the motor functions efficiently and reliably without any electrical leakage or short circuits.

Thermal Stability: Enameled wires possess excellent thermal stability, allowing them to withstand high temperatures generated during motor operation. This capability is crucial for motors that operate under demanding conditions or in environments with elevated temperatures.

Size Optimization: The thin insulation layer on enameled wires enables the winding of coils in a compact manner. This compactness is essential for motors with limited space, as it allows for more turns of wire to be accommodated within the available area, thereby increasing the motor's power density.

Choosing the Right Enamel Type:

Different types of enamel coatings are available, each with unique properties that make them suitable for specific applications. The choice of enamel type depends on factors such as temperature requirements, voltage levels, operating conditions, and the motor's intended use.

Motor Rewinding Process:

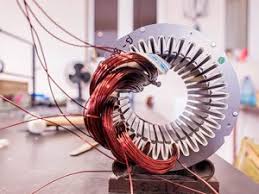

Motor rewinding involves removing the old windings from the stator or rotor and replacing them with new enameled wires. The process typically includes the following steps:

Disassembly: The motor is carefully disassembled, and the old windings are removed, taking care not to damage the core or other components.

Insulation Removal: Any remaining insulation from the old windings is stripped off to expose the core and prepare it for rewinding.

Coil Winding: The new enameled wires are wound around the core in a specific pattern, either by hand or using automated winding machines. The number of turns and the wire gauge must match the motor's requirements.

Connection and Insulation: The wire ends are connected according to the motor's wiring diagram, and insulation materials such as tapes, sleeves, or varnishes are applied to secure the connections and protect against electrical faults.

Testing and Reassembly: The rewound motor is thoroughly tested to ensure proper functionality and performance. Once validated, the motor is reassembled and ready for use.

Conclusion:

Enameled wires are an indispensable component of motor rewinding processes, providing electrical insulation, thermal stability, and size optimization. Their use enhances motor efficiency, reliability, and longevity. By understanding the importance of enameled wires and following proper rewinding techniques, we can breathe new life into electric motors, extending their service life and maintaining peak performance.