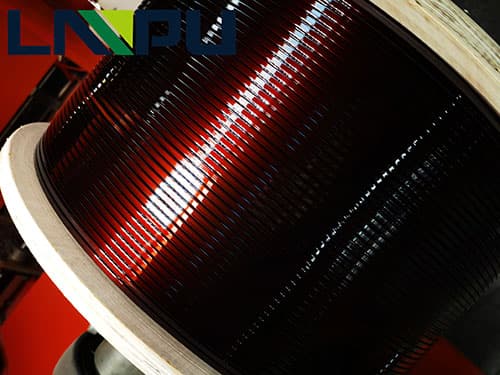

Wire Vanish Coating

Painting is the process of coating the enameled wire paint on the metal conductor to form a uniform paint layer with a certain thickness. The number of painting passes is affected by the solid content, viscosity, surface tension, contact angle, drying speed, painting method, and thickness of the paint layer. The general enameled wire paint needs to be coated and baked many times to make the solvent evaporate fully, the lacquer resin reacts completely, and a good paint film is formed.

Paint speed, paint solid content, surface tension, paint layer, paint viscosity, painting method

Speed Height Size Thickness Height Felt Mould

The first paint layer is more critical. If it is too thin, the paint film will have a certain degree of air permeability, which will oxidize the copper conductor, and finally cause the surface of the enameled wire to bloom. If the thickness is too thick, the cross-linking reaction may not be sufficient and the adhesion of the paint film will decrease, and the tip shrinkage will appear after being pulled off.

The last paint film is thinner, which is beneficial to the scratch resistance of the enameled wire.

In the production of fine gauge lines, the number of paint passes directly affects the appearance and pinhole properties.