Winding method and comparison of interlayer shielding of high frequency transformer

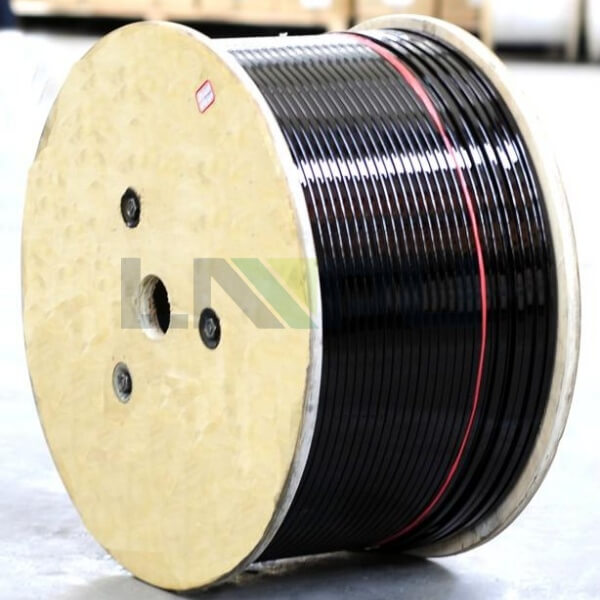

The shielding layer leads a wire to be grounded, which is the reference point of potential. Conventional shielding is done between the primary and secondary windings. Whether it is the outermost layer or the inner winding shielding, you need to pay attention: when the winding is wrapped with copper foil, the copper foil overlaps the ends of the copper foil and needs to be insulated. The reason is simple: if there is no insulation, overlapping and connecting is a short-circuited coil!

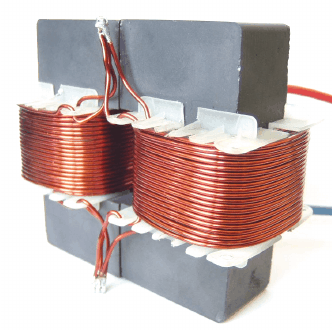

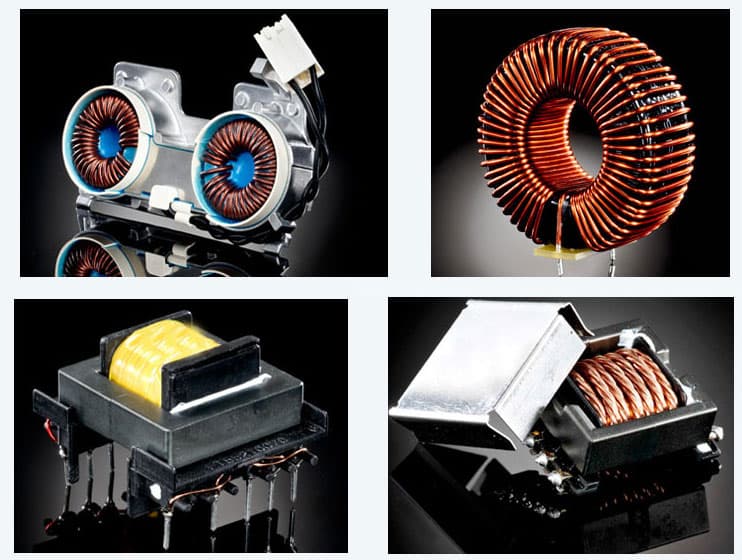

How to add high frequency transformer

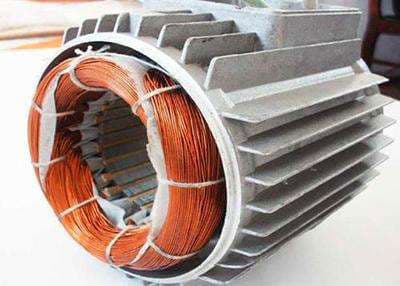

1. Wrap a long strip of copper or aluminum foil between the primary winding and the secondary winding of the power transformer, wrap it in more than one circle, but do not touch (short-circuit) the end and end, and lead to the ground by welding or wrapping. It must have an insulating layer inside and outside, and a secondary winding is wound on its outside.

2. Use an enameled wire with a diameter of 0.1¡«0.3 to close one layer and wind it between the primary winding and the secondary winding of the power transformer, with one end empty and the other end leading to ground. It also has an insulating layer inside and outside.

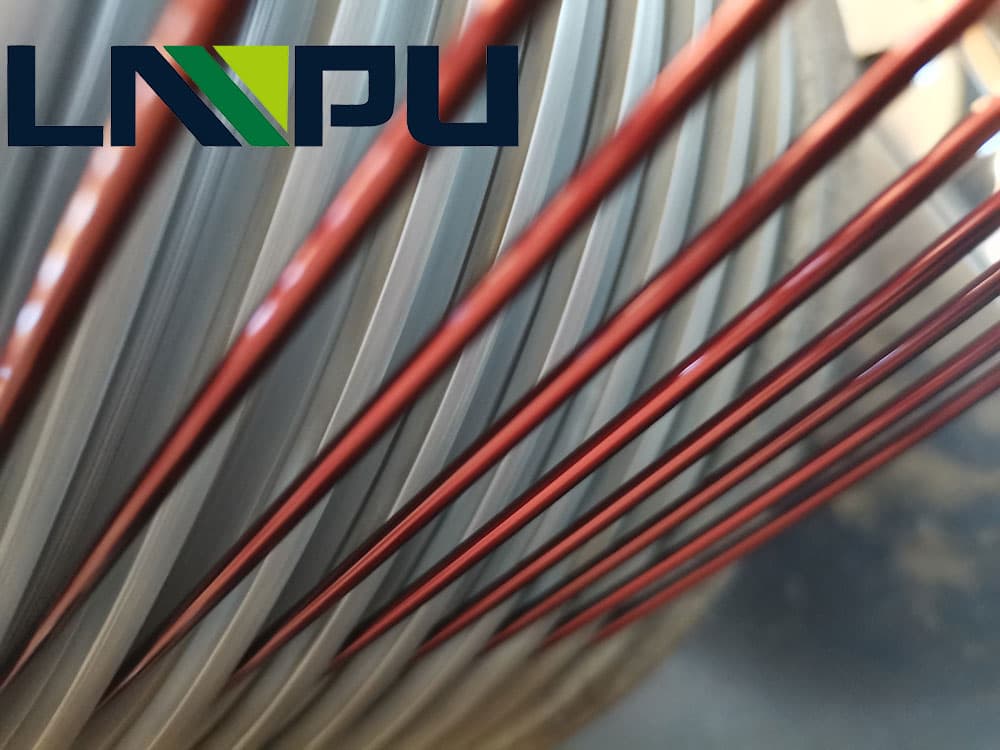

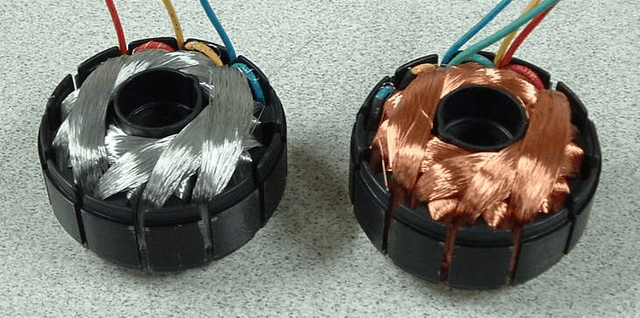

The difference between wire-wound shielding and copper foil shielding in high-frequency transformers

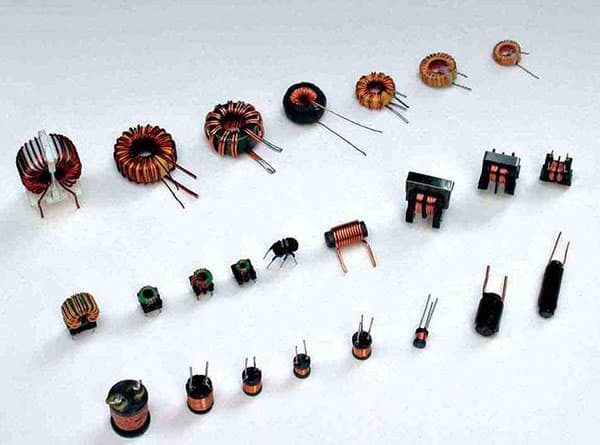

Except for the difference in the process of high-frequency transformers, the shielding effects of wire-wound shielding and copper foil shielding are similar. The specific power supply is not necessarily good enough. As for why wire shielding is used, there are many factors that can be considered, such as cost and efficiency. Another point is that the use of wire shielding can be designed more flexibly, such as the starting point, ending point, and winding direction of the shielding, which will also have a practical impact on the shielding effect.

The cost of shielding with copper wire will be low, it can be automated production, many companies have automatic machines; and the consistency of products produced when shielding with copper wire is very good in EMI testing;

Some shielded copper wires are used as supplementary windings to adjust the internal winding capacitance, which is very convenient to adjust the number of turns, which is commonly used in switching transformers.