Why Copper Wire Is the Metal That Fits the Needs of Electrical Wire Manufacturing Industry

Why Copper Wire Is the Metal That Fits the Needs of Electrical Wire Manufacturing Industry

Key Properties That Makes Copper the Ideal Choice

Favorable Chemical Properties

Can Withstand Changes in Temperatures

Copper wire is the most commonly used wiring material in most residences and commercial establishments. There are many reasons why copper wires are preferred wires of other metals. Copper wire makes the grade because of its ability to conduct electricity easily.

Why Copper Is the Metal of Choice

The atomic structure of copper makes it a great conductor of electricity. Only silver performs better than copper when it comes to conductivity of electricity. However, we all know that silver is several times more expensive conductor than copper making it an unviable option for domestic or commercial wiring.

Key Properties That Makes Copper the Ideal Choice

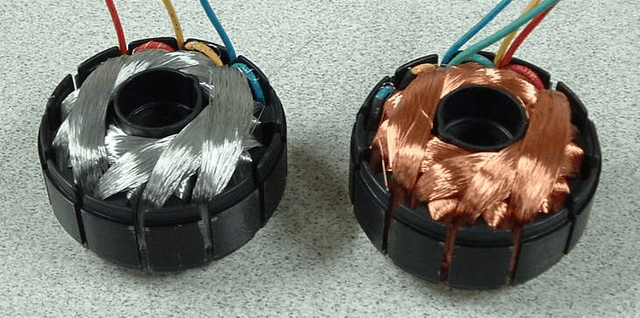

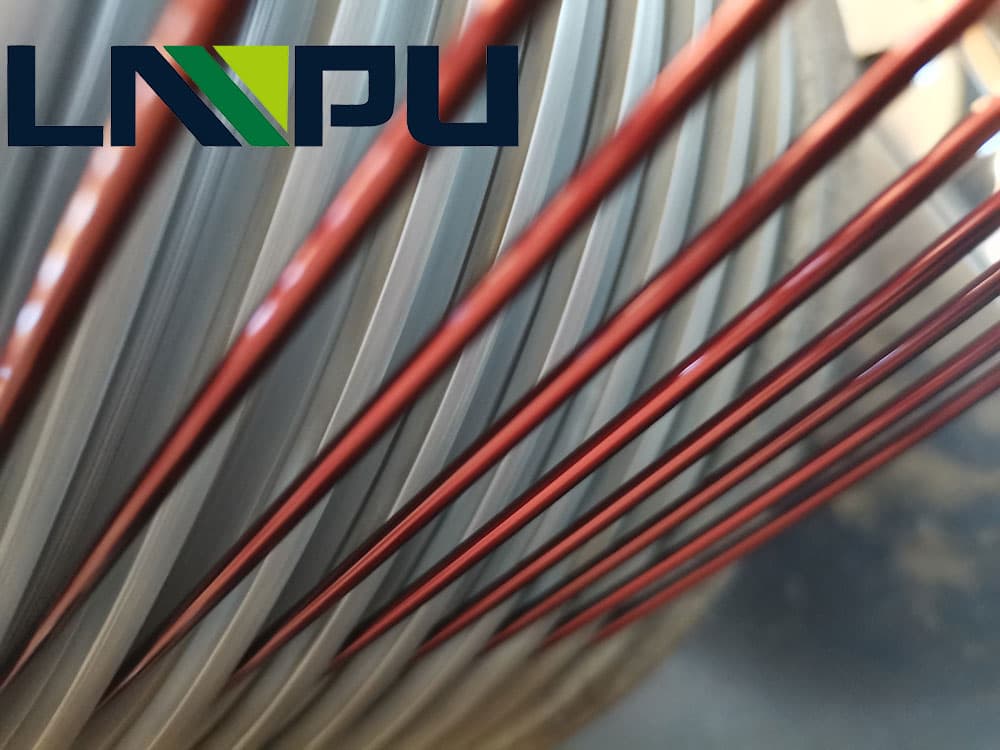

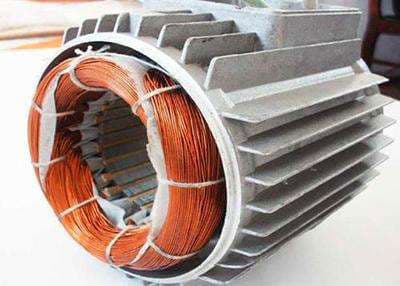

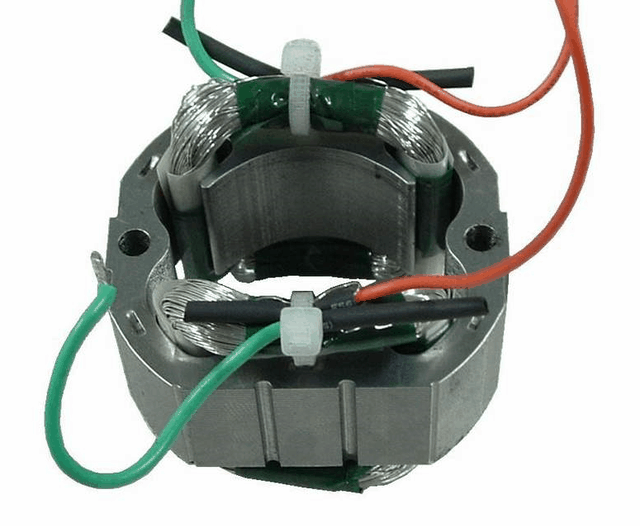

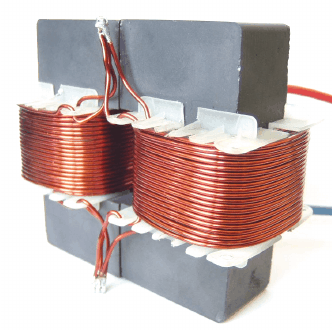

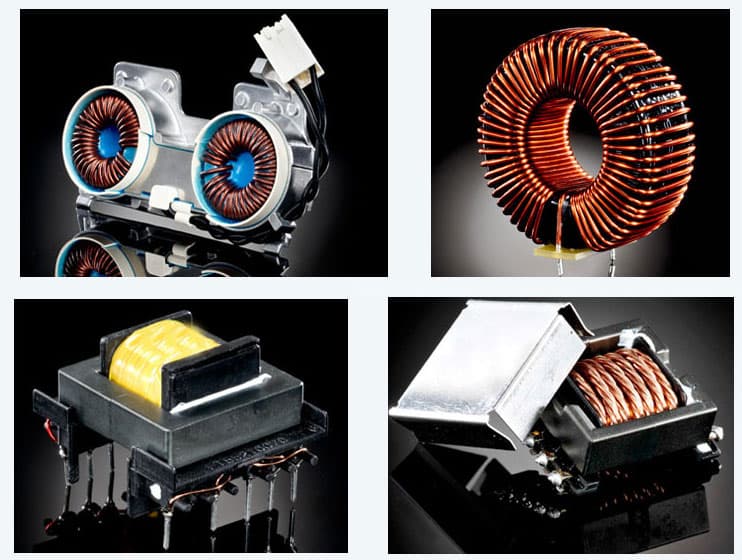

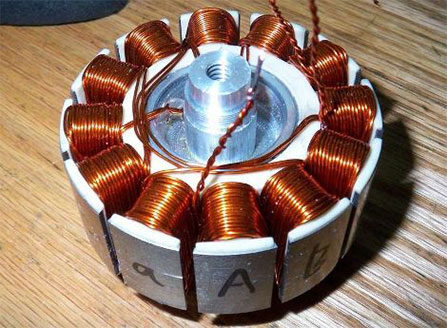

Copper wire is the ideal choice for electrical transmission as it is an excellent conductor of electricity with no other metal able to match its performance in this aspect. According to experts, copper wire has the ability to carry more current per diameter of wire. In technical terms, this mean that copper wire wastes less charge when electricity flows through it thus optimizing utility. The highly ductile copper wire allows it to be stretched to extreme lengths without breaking or losing its strength. This is a much-desired property that manufacturers of wires look for in any metal. It can be drawn into thin, long yet strong wires.

Favorable Chemical Properties

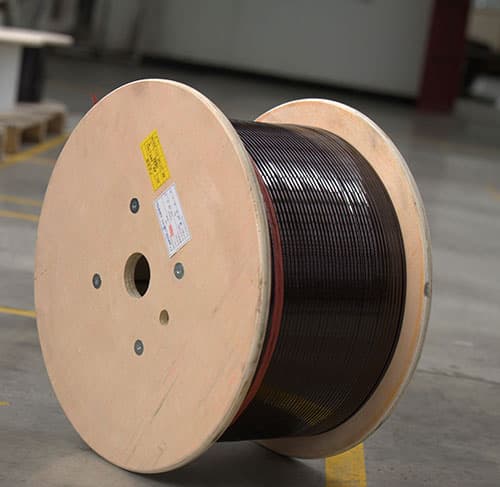

When you take a closer look at the chemical properties of copper wires, it is apparent that the chemical composition of these wires is extremely favorable for electrical industry. It can withstand climatic vagaries, is resistant to abrasion and is extremely durable as well. These chemical factors make copper wires the ideal metal for making wires. They can last long and need not be changed frequently which is also one of the main benefits of using copper wire for electrical works. Copper wire cables can perform at peak efficiency for many years once they are placed in conduits or blocks under the earth because they do not get damaged by weather conditions. Soil does not have any effect on their performance.

Can Withstand Changes in Temperatures

Copper wires are extremely tolerant to changes in temperature. Surface temperature of wires can change significantly when high voltage current passes through them. For electrical wires to withstand high and changing temperature levels they must be made of a material that has the ability to withstand such changes in temperature levels. Copper wire fits the bill perfectly because of its excellent ability to withstand temperature changes. High temperature has no effect on the physical and chemical properties of copper wires.

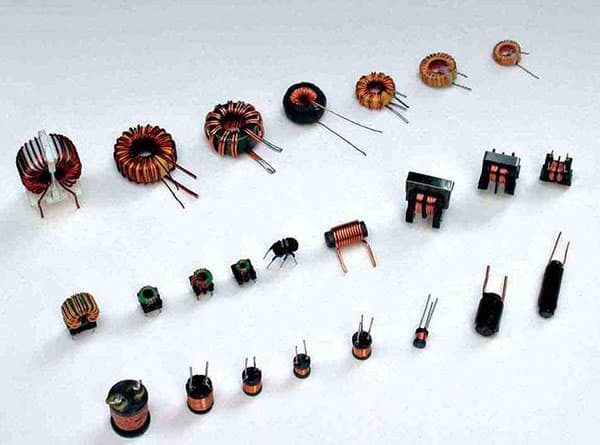

Copper wires are malleable and ductile and can be easily drawn into wires of all sizes and dimensions. Different types of electrical wires are needed for meeting various types of electrical applications in residential as well as commercial wiring. Copper wires of various dimensions can be manufactured to meet the varied demands of the electrical industry.

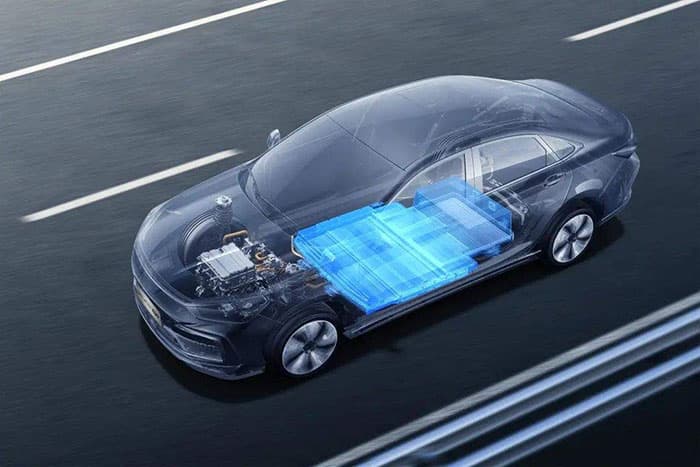

Copper has been the key component of electrical wires since the 1800s. Today, more than half of the global copper wires manufactured are used for electrical transmission needs. With the exception of transmission lines that require materials capable of handling high voltage, copper is present in everything else associated with electricity in homes, offices, commercial establishments and industrial units.