What is the role of enameled wire in the motor?

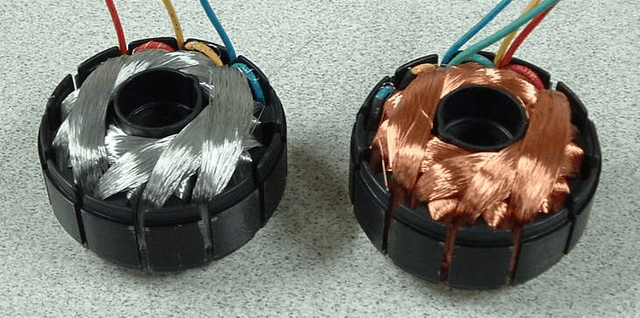

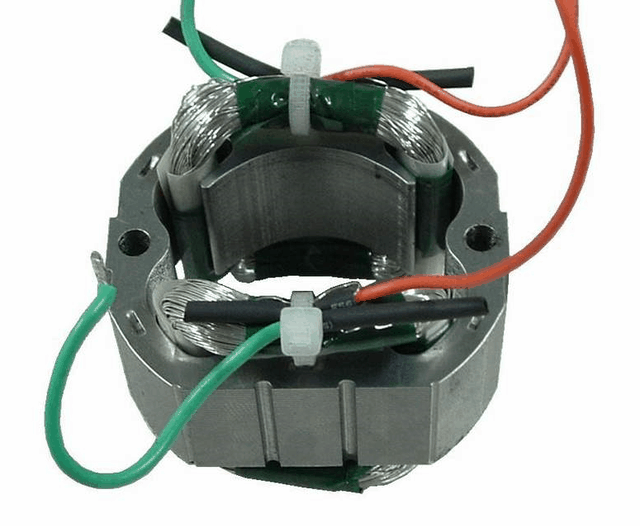

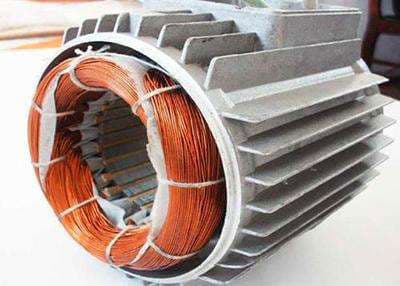

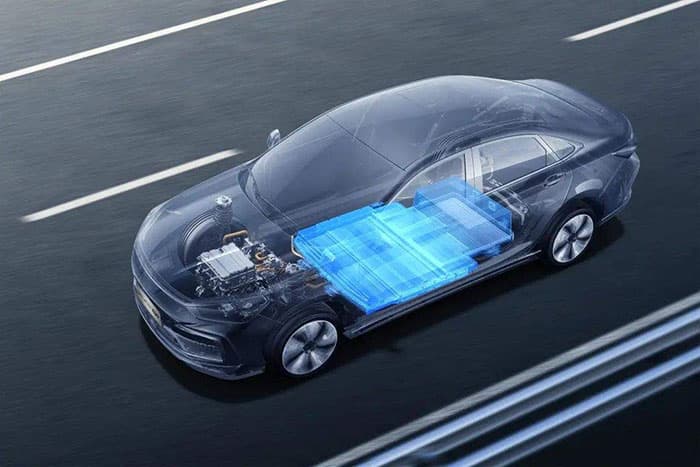

Permanent magnet brushed DC motor: The coil wound by the enameled wire is the armature winding of the motor. The armature winding converts electricity into a magnetic field, and then interacts with the magnetic field of the permanent magnet. The attraction and repulsion between the two magnetic poles drive the motor Rotate.

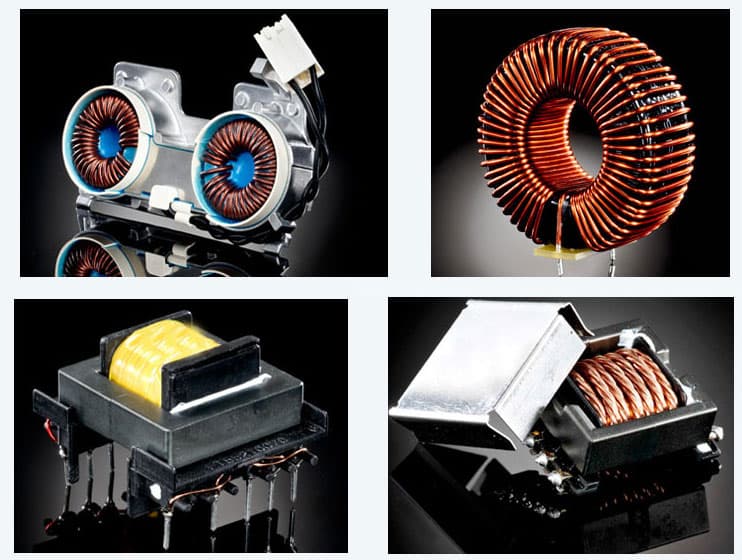

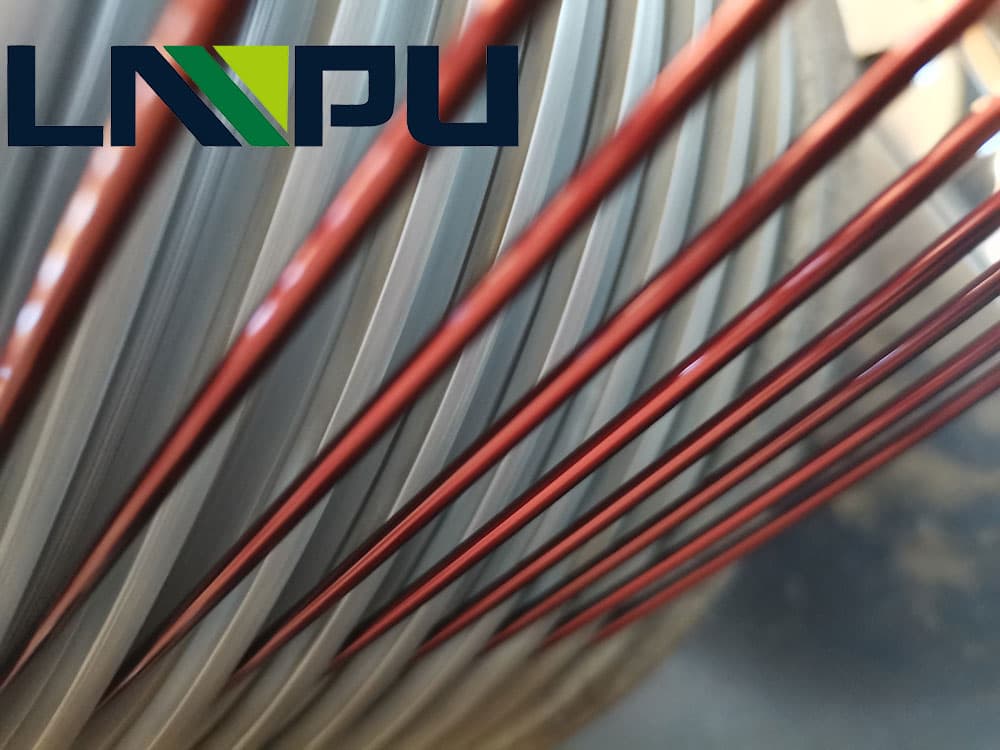

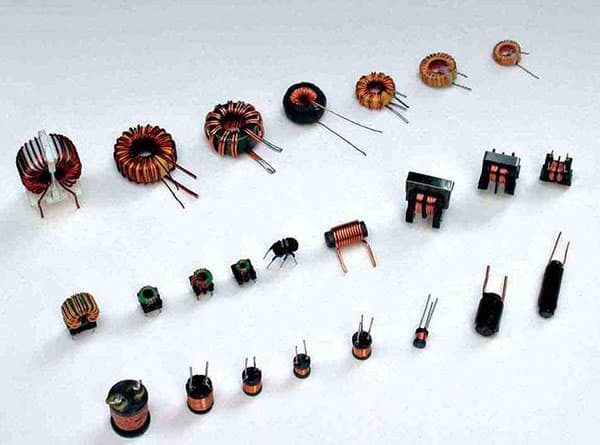

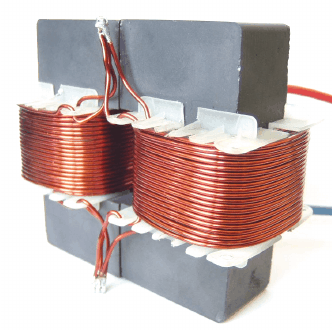

Motor torque formula: T=30P/(n¦Ð), P is power, n is speed, where P is the product of input power P1 and efficiency ¦Ç, that is, formula 1: T=30¦ÇP1/(n¦Ð) Next, look at speed n, formula 2: n=(U-RI)/Ce¦ÕU is the armature voltage; R is the armature loop resistance; I is the armature current; ¦Õ is the main magnetic flux of the motor air gap; Ce is the electric potential constant, formula 3: Ce=pN/ (60a) Among them, p is the electromagnetic logarithm, a is the number of armature parallel branches, and N is the number of turns. The efficiency ¦Ç is mainly determined by the manufacturing process and the actual load characteristics, and the detailed discussion is skipped. Among them, the armature winding, that is, the winding of the enameled wire in the figure affects the following parameters: 1) the characteristic curve of efficiency ¦Ç 2) N: the number of turns 3) a: the number of armature parallel branches (and the winding direction of the coil The methods are related, including wave winding, stacked winding, frog winding, etc.) 4) R: armature loop resistance, determined by the material of the enameled wire itself and the length of the winding. Therefore, the winding of the armature winding is directly related to the torque and speed of the motor. For the torque problem, according to Equation 1, the higher the efficiency ¦Ç, the greater the input power, and the slower the speed, the greater the torque. Regarding the speed problem, according to Equations 2 and 3, it is considered that the externally input voltage U, magnetic flux ¦Õ, and electromagnetic logarithm (the motor is fixed as a pair of magnets, mounted on the two protruding ends of the flat shape) are basically the same, It is mainly related to the material, winding method and total number of turns of the enameled wire. The smaller the winding resistance, the less the number of turns N, the greater the number of armature parallel branches a, and the faster the speed.