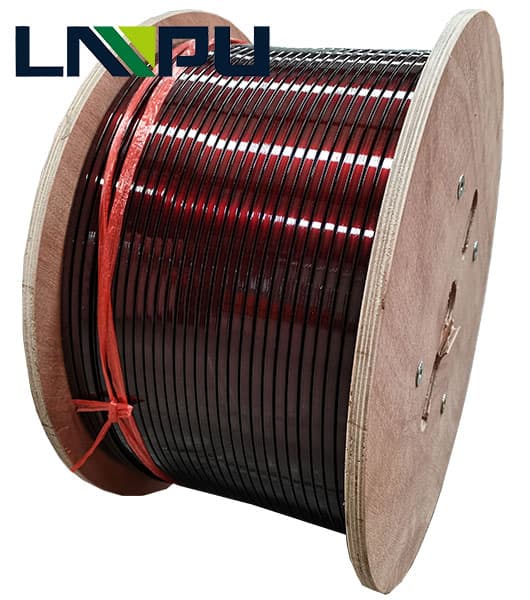

What is the function of enamel?

1. Mechanical function: including elongation, return angle, softness and adhesion, scraping, tensile strength and other items.

2. Heat resistance: including thermal shock and softening breakdown test.

3. Electricity includes: breakdown voltage, lacquer film continuity and DC resistance test.

4. Chemical resistance includes solvent resistance and welding.

What are the function of the enamel

1. Mechanical function: including elongation, return angle, softness and adhesion, scraping, tensile strength and other items.

(1) The plastic degeneration of the elongation reflect the material for inspecting the ductility of the enamel wire.

(2) Back Edge, softness reflects the elastic deformation of the material for inspection of the softness of the enameled wire.

(3) The durability of the paint film includes wound and stretching, i.e., the lacquer film with the laminated mandarin deformation of the lacquer film without cracking.

(4) The adhesion of the paint film includes an urgent pull-off, peeling, first examining the adhesion of the paint film on the conductor.

(5) The scratch test of the paint film reflects the strength of the paint film anti-mechanical scratch.

2. Heat resistance: including thermal shock and softening breakdown test.

(1) The thermal impact of the enameled wire is to observe the paint film of the paint wire to heat the heat under mechanical stress. Factors affecting thermal shock: paint, copper wires and enameled kits.

(2) The softening failure function of the enamel wire is to measure the ability of the paint film of the paint wire to heat the deformation under mechanical force, that is, the pressure-pressed film is plasticized in high temperatures. The unevenness of the heat-resistant softening function of the lacquer wire paint film depends on the force between the molecular structure of the paint film and the molecular chain.

Electricity includes: breakdown voltage, lacquer film continuity and DC resistance test.

The breakdown voltage refers to the capacity of the voltage load to which the paint coated film is affected. The main influencing factors of breakdown voltage: paint film thickness; paint film circle intensity; curing degree; paint film external impurities.

Paint film continuity test is also known as pinhole test, and its main influencing factors are: raw materials; operation technology; equipment.

(3) DC resistance refers to the resistance value measured by unit length. Its main influencing factors: (1) annealing; (2) paint packaging equipment.

4. Chemical resistance includes solvent resistance and welding.

(1) Solvent-resistant function, generally paint wiring wires to coil after the impregnation process, the solvent in the impregnated lacquer has different degrees of expansion effect on the paint film, which is more severe at higher temperatures. The chemical resistance of the paint film is mainly dependent on the characteristics of the paint film itself. Under certain conditions of the paint film, the paint film process has a certain effect on the solvent resistance of the paint film.

(2) Direct welding function of the enameled wire reflects the ability of the enameled wire in the process of soldering during the entanglement of the paint film. The main factors affecting direct welding performance are: process impact; the effect of paint.