What is the difference between polyester enameled wire and polyurethane enameled wire?

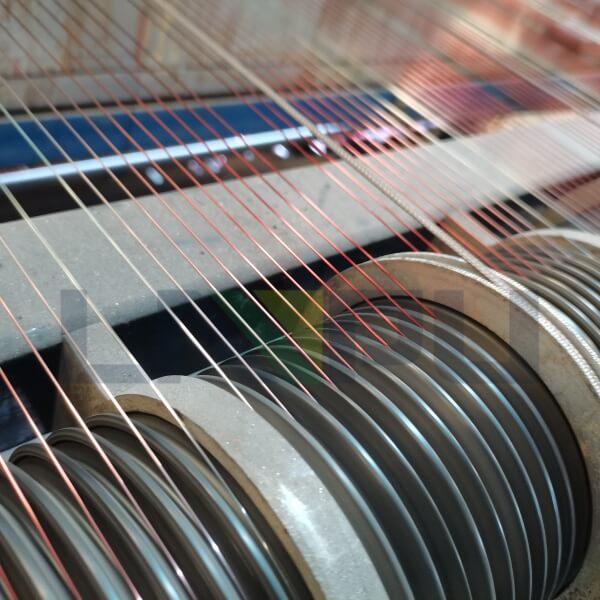

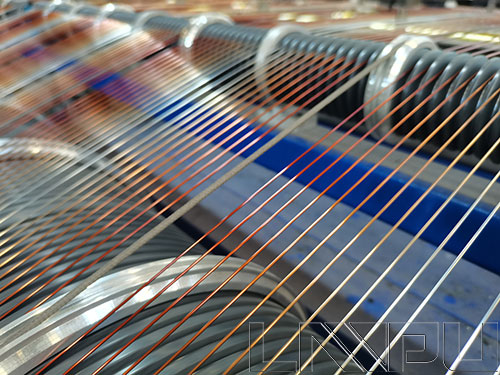

There are some differences between polyester enameled wire and polyurethane enameled wire in terms of use occasions and performance:

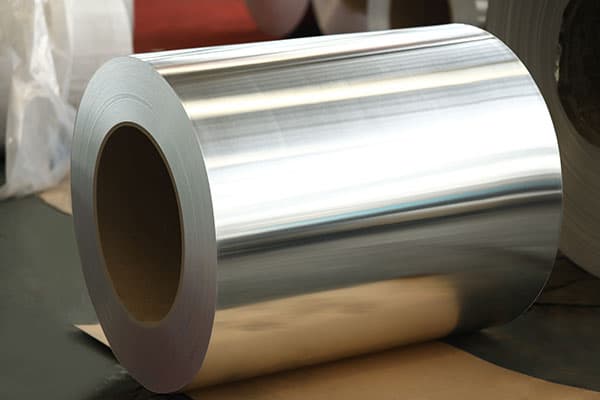

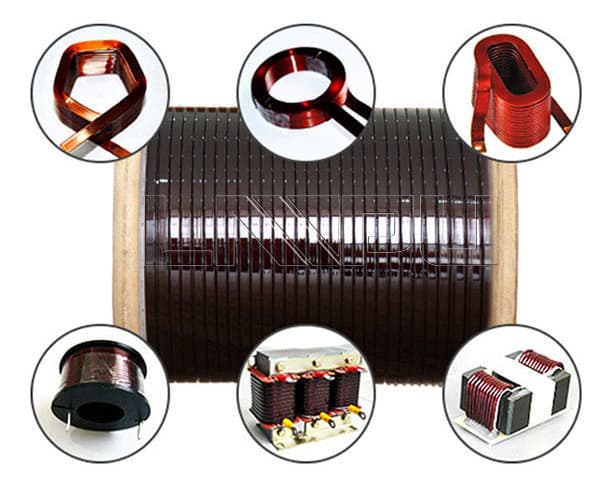

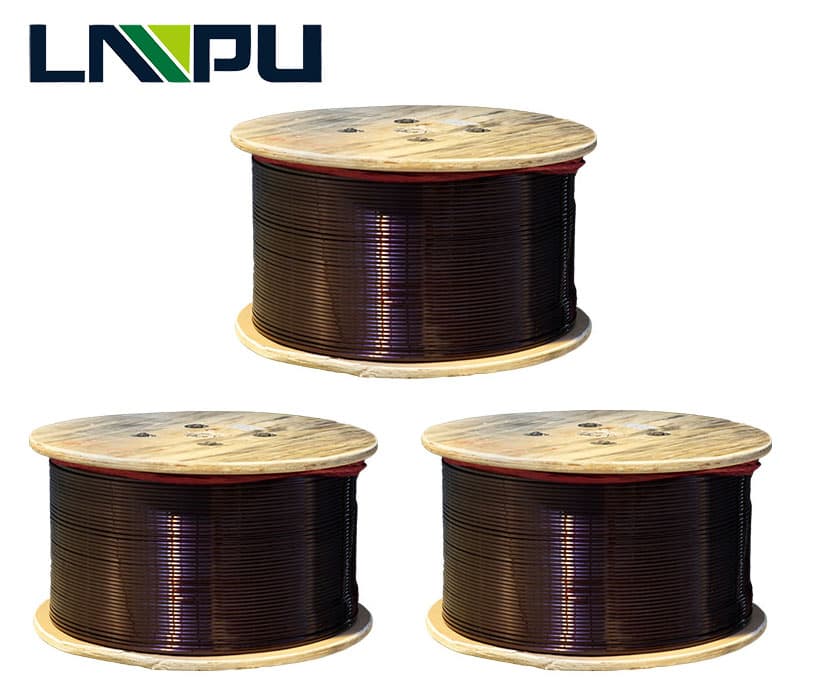

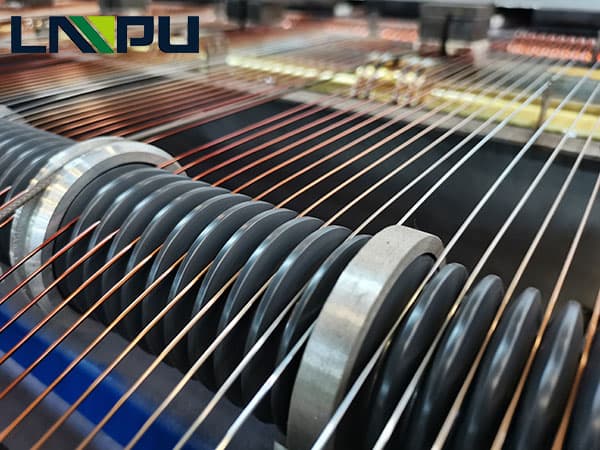

Polyester enameled wire, composed of copper conductor and polyester resin, has a thermal class of 130, and after modification, the thermal class of the enameled wire is 155. It has good mechanical strength, paint film adhesion, excellent electrical, scratch resistance, chemical resistance, thermal stability and solvent resistance. It is widely used in various motors, electrical appliances, meters, telecommunications equipment and home appliances; the weakness of this product is poor thermal shock resistance and low moisture resistance.

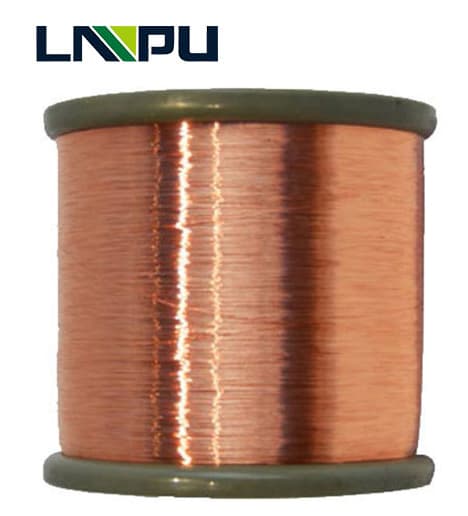

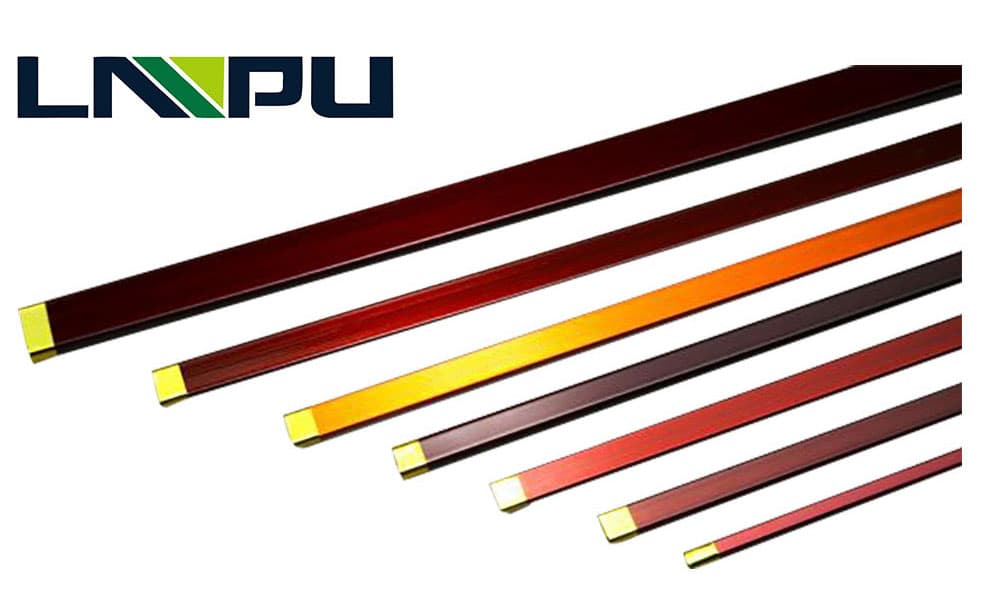

Polyurethane enameled wire, thermal grade is 130,155,180. The biggest feature is that it has direct solderability, good high frequency resistance, easy coloring, and good moisture resistance. It is widely used in electronic appliances, precision instruments, telecommunications, and meters. The weakness of this product is that the mechanical strength is slightly poor, and the heat resistance is not high. , And the flexibility and adhesion of the production of large-size wires are poor, so the specifications of the product are mostly small and medium-sized wires.