What is the difference between enameled wire and triple insulated wire

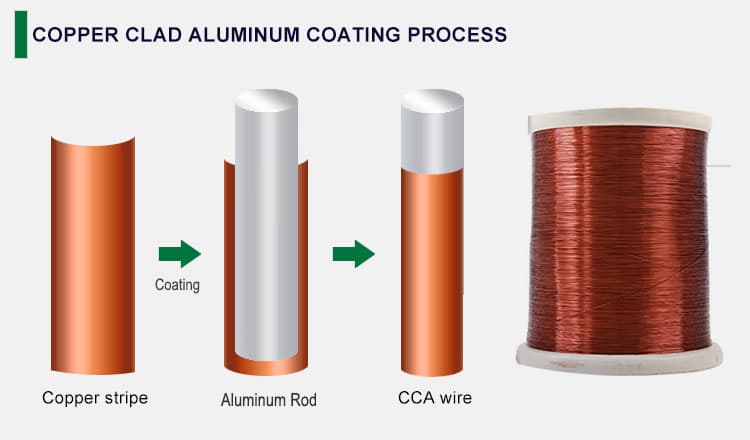

1. Different materials: structure and composition are different

2. Different performance: Since the three-layer insulated wire cannot be directly welded, it needs to be stripped first, and the cost is higher, and it will be replaced by FIW; the insulation level is different, and the three-layer insulated wire can be produced with a temperature resistance of 200 degrees

3. Can be different in color, etc.

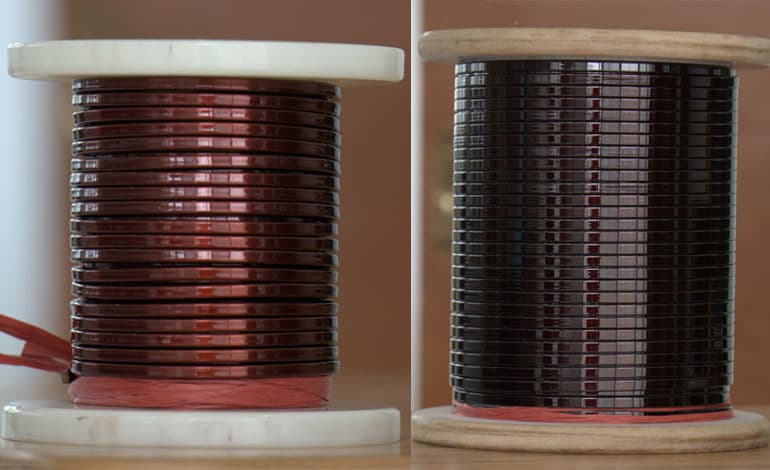

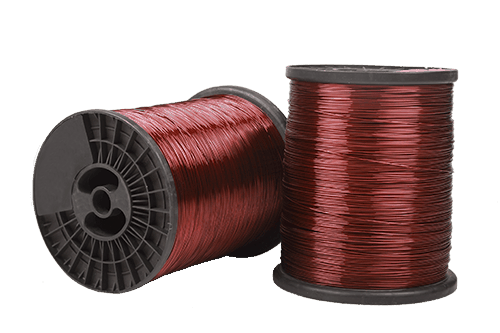

Variety of enameled wire:

1. Polyesterimide enameled wire 2. Polyesterimide enameled wire (direct solderability) 3. Polyurethane coated polyimide enameled wire 4. Polyurethane enameled wire 5. Polyurethane enameled wire 6. Polyurethane coated nylon enameled wire 7. Polyester enameled wire 8. Polyester ceramic coated nylon enameled wire 9. Polyamine ceramic coated polyimide enameled wire 10 Polyimide enameled wire

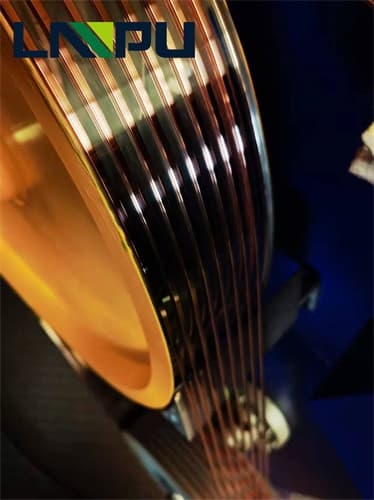

TRIPLE INSULATION WINDING WIRE is a high-performance insulated wire. This wire has three insulating layers, with a copper core in the middle, and the first layer is a golden yellow polyamine film with a thickness of several microns , But can withstand 2KV pulse high voltage, the second layer is a highly insulating spray paint coating, and the third layer is a transparent nylon modified glass fiber layer. The total thickness of the insulating layer is only 20-100um. Its advantage is the insulation strength. High, any two layers can withstand the safe voltage of AC 2000V, and the current density is high. The weight and volume of the transformer can be reduced.