What is enameled wire? What are the characteristics?

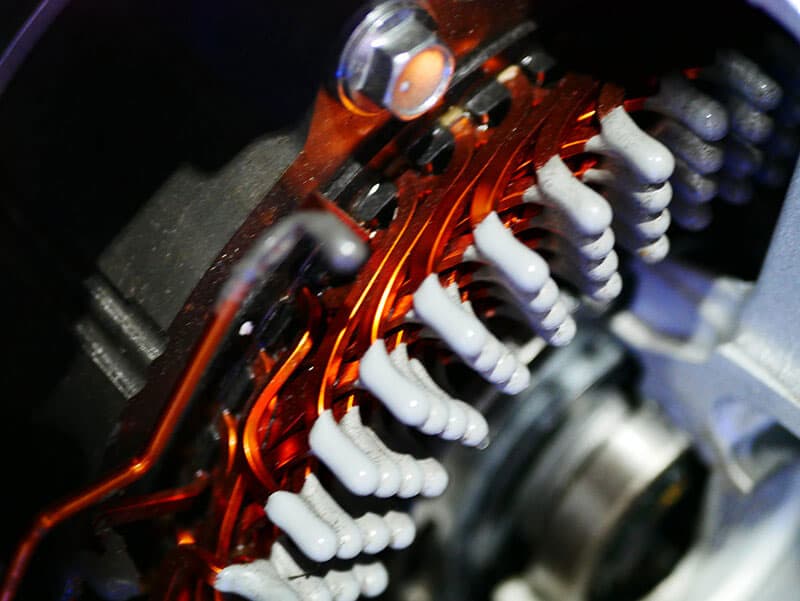

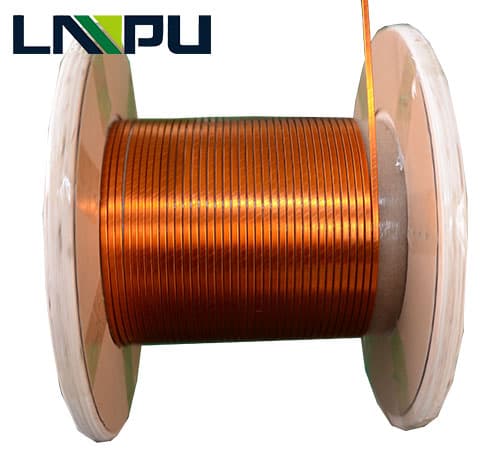

Enameled wire is widely used in our production and life. The paint it uses is a kind of paint that can produce a good insulating layer between the wires in the winding.

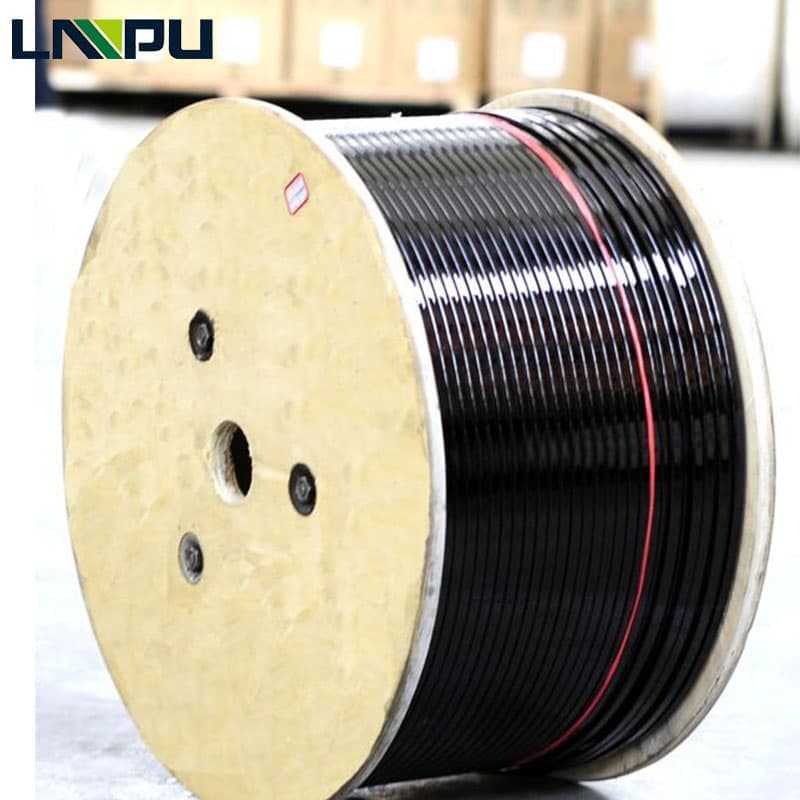

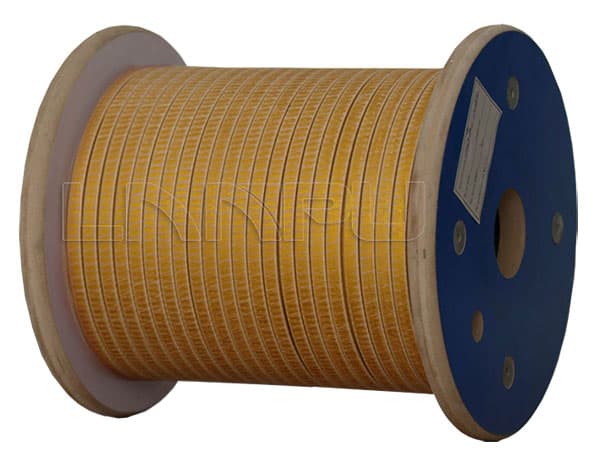

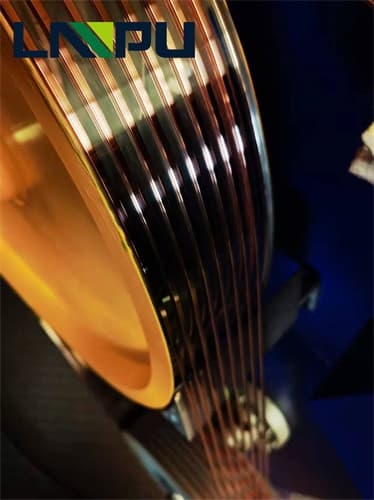

Enameled wire is made on the basis of copper wire. Simply put, enameled wire is a layer of insulator on the copper wire, usually plastic. Enameled wire paint is a kind of outer layer of bare copper wire, alloy wire and glass wire covered wire of various wire diameters to improve and stabilize the performance of enameled wire. It has high mechanical strength, resistance to Freon refrigerant, good compatibility with impregnating paint, and can meet the requirements of heat resistance, impact resistance, oil resistance, etc.

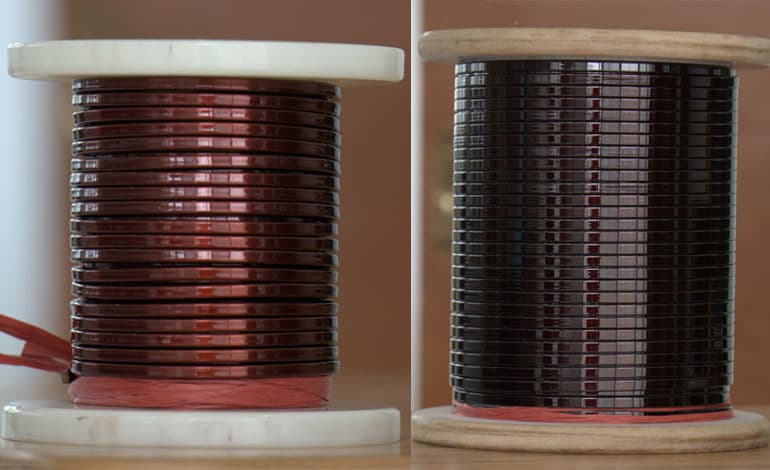

Enameled wire is a main type of winding wire. It is composed of a conductor and an insulating layer. After the bare wire is softened by annealing, it is painted and baked many times. However, it is not easy to produce products that not only meet the requirements of the standard, but also meet the requirements of customers. It is affected by the quality of raw materials, process parameters, production equipment, environment and other factors. Therefore, the quality characteristics of various enameled wires are different, but they all have Mechanical properties, chemical properties, electrical properties, and thermal properties are four major properties.

Enameled wires are classified according to their purposes: ordinary wires, heat-resistant enameled wires, and enameled wires for special purposes.

1. General purpose enameled wire (ordinary wire): Mainly used for winding wires in general motors, electrical appliances, instruments, transformers, etc., such as polyester enameled wire and modified polyester enameled wire. Only a small amount of single-coated polyester imine enameled wire is applied with domestic paint, but the voltage instability is still a concern of the manufacturer. The direct solderable polyester imine paint has been successfully developed by the Cable Research Institute.

2. Heat-resistant enameled wire: Mainly used for winding wires in working places such as motors, electrical appliances, instruments, transformers, etc. that work in a temperature environment of 180¡æ and above, such as polyester imide enameled wire, polyimide enameled wire, polyester enameled wire, polyester Imine/polyamideimide composite enameled wire.

3. Special purpose enameled wire: refers to the winding wire that has certain quality characteristics and is used for specific occasions, such as: polyurethane enameled wire (direct welding), self-adhesive enameled wire.