What is enamel wire coating?

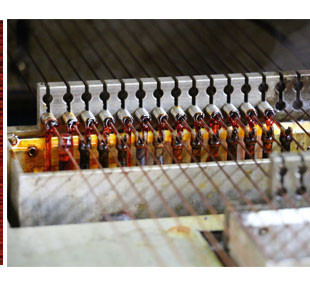

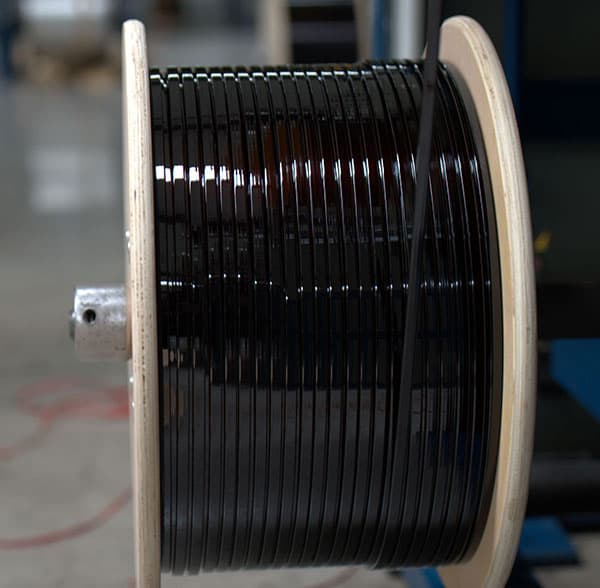

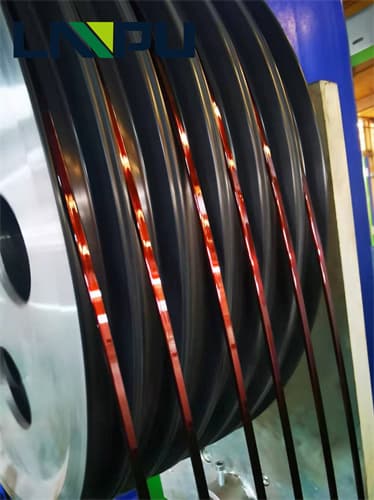

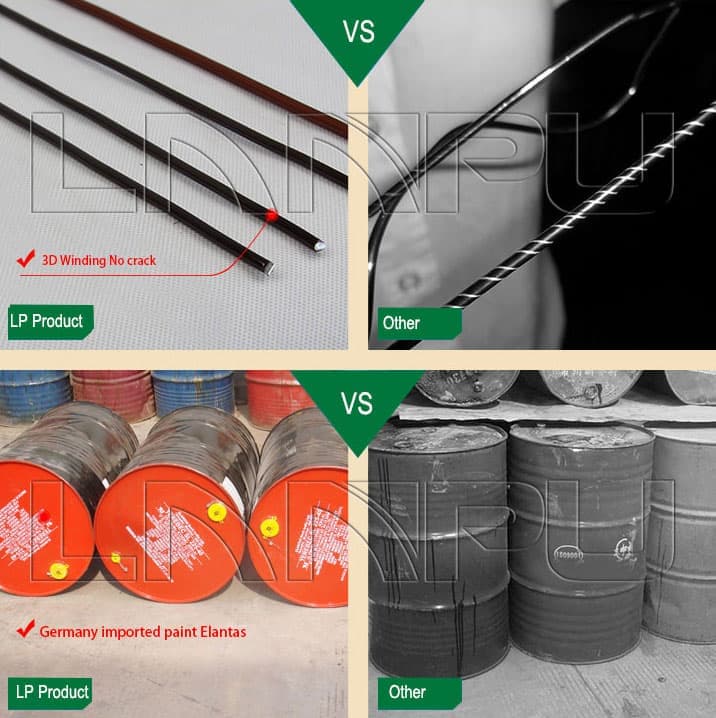

Enameled wire coating is mainly used for coating and insulation of enameled wire cores. Since the wire will be subjected to heat, chemical and various mechanical forces in the process of winding coils and embedding wires, the enameled wire paint is required to have good coating properties (that is, uniform coating), and strong paint film adhesion.

The surface is smooth, soft and tough, with certain abrasion resistance and elasticity, good electrical performance, heat resistance, solvent resistance, and non-corrosion to conductors. Specifically divided into the following nine types.

1. The main component of acetal paint is polyvinyl formal, which is used in the production of enameled wires for oil-containing transformers.

2. The main component of polyurethane paint is polyurethane, which is widely used in the production of enameled wires for electronic transformers, electronic coils, relays, micro-motors, high-frequency electrical appliances and other electronic windings.

3. Solderable polyester imine paint has the general performance of polyester imine paint, and it can be welded directly at 475.

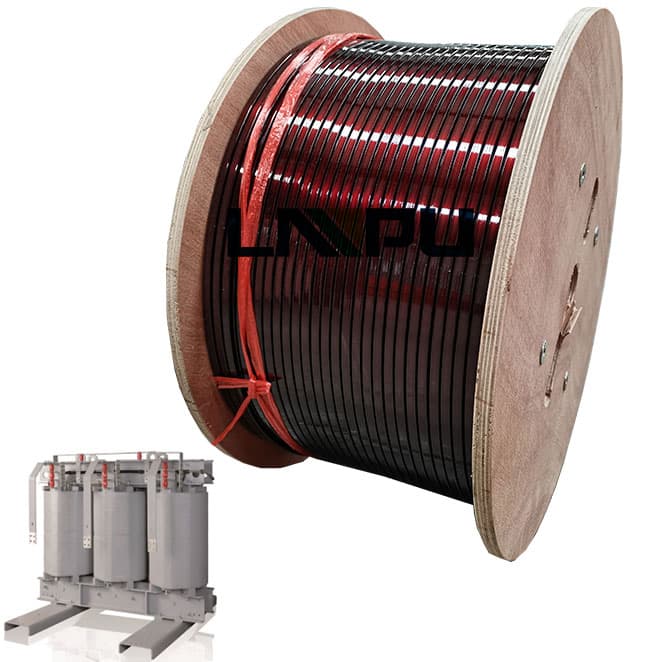

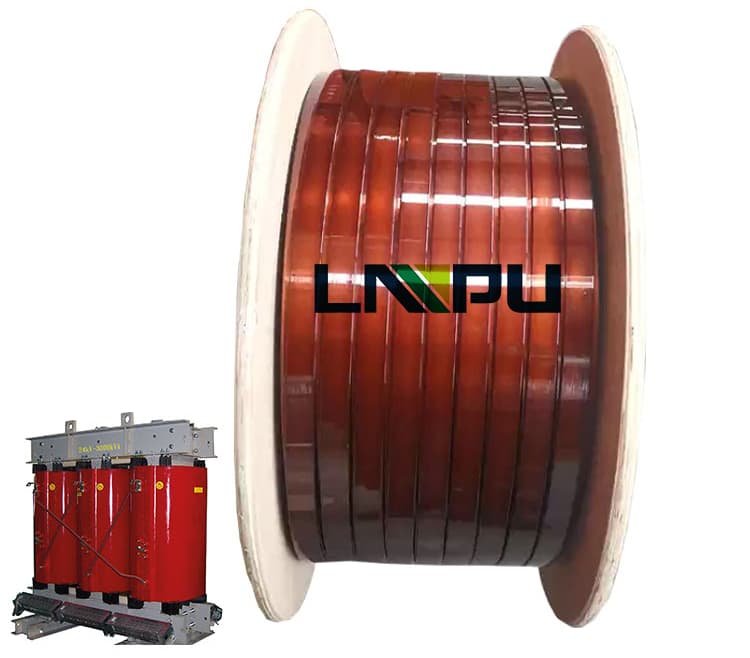

4. Polyesterimide paint is the most widely used type of enameled wire paint. It has excellent thermal properties, usually higher than 180. It can be single-coated or used as a primer and polyamide-imide or nylon paint to produce composite wires. It is widely used in refrigerators and air-conditioning compressors, explosion-proof motors, power tools, ballasts, dry-type transformers and other occasions with higher insulation levels.

5. The main component of polyester paint is polyester with good overall performance. It is used in the production of enameled wire for washing machine motors, micro motors, instruments and telecommunication equipment, power tools and ordinary motors. The heat-resistant polyester is modified by Seck, and a large number of primers are also compounded with polyamide-imide for the production of refrigerant-resistant enameled wire.

6. Polyamide-imide is the most widely used high heat-resistant grade (220) enameled wire paint, mostly used as a top coat production compound wire to improve the comprehensive performance of the enameled wire. It is widely used in the production of sealed motors and refrigerant-resistant enameled wires. Some products can also be applied individually. In order to improve the performance of enameled wire, it can also be made into self-lubricating type and filler. It has great applications in heavy-duty motors and automotive industries.

7. Polyesterimide paint thermal grade 240, superior performance, and its enameled wire is radiation resistant.

8. Nylon paint uses its lubricity and is generally used on the surface of enameled wire. There are also improvements to other properties.

9. The self-adhesive paint is very different according to the composition used. There are mainly different types of self-adhesive paint such as polyamide, epoxy (phenol oxygen) and aromatic polyamide. Generally used as enameled wire finish. Used for bonding and molding of deflection coils, transposition wires, voice coils and coils of opposite sex.