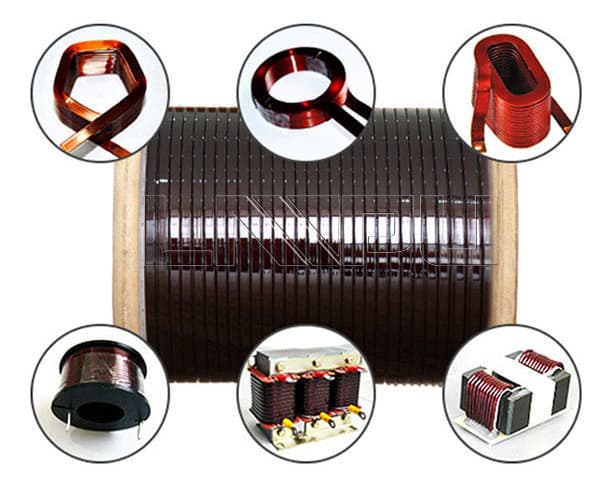

What details should be paid attention to when making enameled wire?

Although the quality of enameled wire depends to a large extent on the quality of raw materials such as paint and wires and the objective conditions of machinery and equipment, if you do not take a series of problems such as baking, annealing, and speed, and understand their interrelationships. , Do not master the operation technology, do not seriously do the touring work, stop and tidy up the work, do not do well in the process and hygiene, even if the objective conditions are good, it will not be able to produce high-quality enameled wire. Therefore, the decisive factor for good enameled wire is people’s sense of responsibility for work.

1. Before starting the catalytic combustion hot air circulation enameling machine, the fan should be turned on to make the air in the furnace circulate at a slow speed. The furnace and the catalytic zone are heated by electric heating, so that the temperature of the catalytic zone reaches the specified catalyst light-off temperature.

2. “Three Qin” and “Three Checks” in production operations.

The diligent paint film is measured once an hour, and the zero position of the micrometer card is corrected before the measurement. When measuring the line, the micrometer and the line keep the same speed, and the big line should be measured in two mutually perpendicular upwards.

Frequent school wiring often observe the back and forth wiring and tension tightness, and correct it in time. Check whether the lubricating oil is proper.

Check the surface frequently to observe whether the enameled wire has any defects such as graininess and paint peeling during the coating process, find out the cause, and correct it immediately. For the defective products on the car, move off the axle in time.

Check the operation to check whether the running parts are normal, pay attention to the tightness of the pay-off shaft, to prevent the rolling head, wire breakage and wire diameter thinning.

Check the temperature, speed and viscosity according to the process requirements.

Continue to pay attention to whether the raw materials meet the technical requirements during the production process of raw materials.