What are the types of enamel wire?

1. Acetal enamel wire.

2. Polyester enameled wire

3.Pu enamel wire.

4.Polyester iminelin wire

5.Polyimide enameled wire

6. Polyamide imide enameled wire

Paint Breadwire Type:

1. Acetal enamel wire.

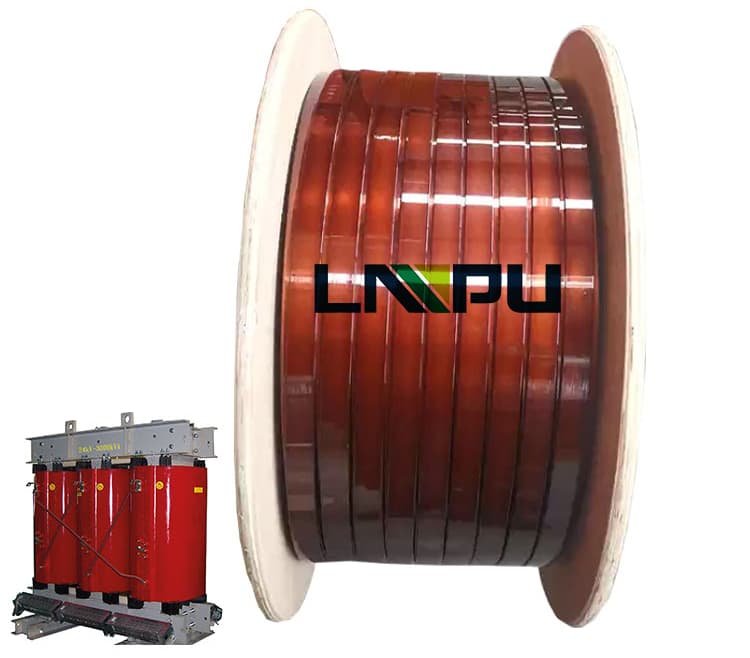

The acetal enamel is one of the earlier varieties in the world. In 1930, the United States has been put into investment, and the Soviet Union has also developed very fast. In the 1960s, my country was successfully developed. Although this enamel wire is low in temperature resistance (105 ¡ã C, 120 ¡ã C), it is widely used in the oil immersion transformer, because of its poor temperature temperature, it is widely used in the oil immersion transformer, and is still in China There are a few production, especially the acetal enameled flat wire for transposition wires for large transformers.

2. Polyester enameled wire.

In the 1950s, West Germany first developed a polyester painted coated wire paint with dimethyl dimethyl nimeticate, because it has better heat resistance and mechanical strength, its lacquer Wide, low price, has become the primary product of the lead enameled wire shopping mall from the 1950s. However, due to the difference in heat resistance of polyester paint wire, it is easy to hydrolysis under high temperature and high humidity conditions. The polyester enameled wire used as a single-layer coating is no longer produced in the late 1970s, in Japan, my country and Southeast Asia are still large. Production and application. According to statistics in 1986, my country’s polyester enamel wire output value accounted for 96 times the total output value. After 10 years of hard work, the variety began to develop, but the gap with developed countries was large.

Domestic polyester modification has also made a lot of work, theic modification, imine modification and other aspects have been studied, but because the structure of the lacquer wire structure is slow, the birth rate of these two coatings is currently Not high. Prior to this, there was a problem about the decwire in modified polyester enameled wire voltage.

3.Pu enamel wire.

Due to its direct welding, high-frequency dyeness and dyeness, it is widely used in the fields of electronics and electrical appliances, and Germany’s Bayer is developed by polyurethane paint lacquer in 1937. Today, foreign progressive polyurethane enamel wires do not affect its direct welding performance. It is now developed in Europe, the United States, and Japan, H-class polyurethane paint wraps. Due to the rapid development of color TV, Japan’s colored FBT developed with a large length of salt-free polyurethane paint wire, still Japan.

my country’s polyurethane enamel wire is slow, and although ordinary polyurethane paints have some manufacturers, they are mainly imported due to process levels and surface quality problems. Domestic F-level polyurethane has also been developed, but has not yet formed production capacity. Large-scale-free porous polyurethane paints have also been successful, first used to produce black and white TV FBT coils and put into the mall.

4. Polyester iminelin wire.

Since polyester is modified to improve its heat resistance, since the 1970s, the amount of polyester orthopedic lacquer wires around the world has increased dramatically, and the lacquer wire is replaced with a single coating polyester in Europe and the United States. Enameled wire has been replacedSingle coated polyester paint wire, from the 1970s, the usual amount of polyester imine lacquer wires in the world has increased dramatically. It has been developed, and the polyester imine lacquer wire has been developed, and is widely used in small motors to simplify the welding process, which reduces motor manufacturing costs. In Japan, there is also a color TV-deflected coil primer using direct solder polyester imide lacquer as self-adhesive wrap, simplifying the process. Domestic polyester imine painted has been introduced from Germany, Italy, also has successful development, but due to the instability of raw materials, the current polyester imide lacquer in China is still relying on imported. Single-layer polyester imine lacquer wire only has a small number of domestic paints, but the voltage instability is still worried that the manufacturer is worried, and the direct solder polyester imine painted has been successfully developed by the wire.

5. Polyimide enameled wire.

The currently temperature-resistant polyimide paint in the organic paint wire is now a long-term use temperature of 220 ¡ã C. This coating was successfully developed in the United States in 1958. Polyester enameled wire has high heat resistance, excellent solvent resistant and freezing resistance. However, due to the high cost, poor storage stability, toxicity, which affects its wide application. This enamel wire is currently used in some special occasions such as coal mine motor, space instrumentation, and the like.

6. Polyamide imide.

The polyamide imide is a good performance in the paint lacquer, with high heat resistance, mechanical properties, anti-freezing function and chemical resistance, and thus is called lacquer lacquer. At present, the coating is mainly based on its unique function, widely used as the face paint of composite coated enameled wires, improves the heat resistance of composite wires and cost reduction. At present, the country is mainly used with its coated freezed-resistant enameled wires, and this lacquer is a small number of domestic products, mainly imports from the United States, Italy and Germany.

7. Coating composite lacquer wire.

Improve temperature-resistant level and special enameled wires, generally use composite insulating layers. Composite lacquer wires have the following advantages compared to single coated lacquer wires: (1) to meet special applications, such as complex non-skeleton molding, self-adhesive enameled wires, refrigerators, air conditioning compressors with cold-frozen-resistant paint package wire, etc. Structure is met; (2) After the composite of various insulating layers, the characteristics will lead their characteristics to avoid weaknesses, improve and advance application functions to meet application requirements, such as polyester / nylon composite coated lacquered wire, thermal shock function and winding function, suitable for heat The impregnation process can be used to reduce the cost of use by the motor due to overload.