What are the requirements for the function and quality of the insulating paint used in the motor?

The insulating paint used in the motor can be divided into six types according to its purpose: impregnating paint, enameled wire paint, covering paint, silicon steel sheet paint, anti-corona paint and surface anti-rust paint.

Its role and quality requirements are as follows:

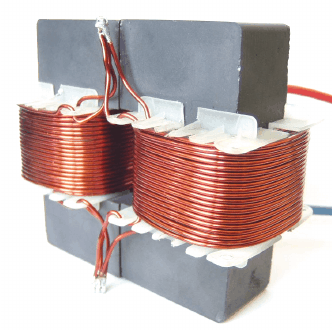

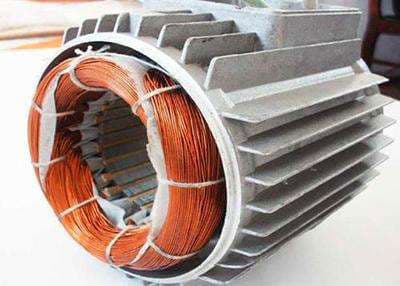

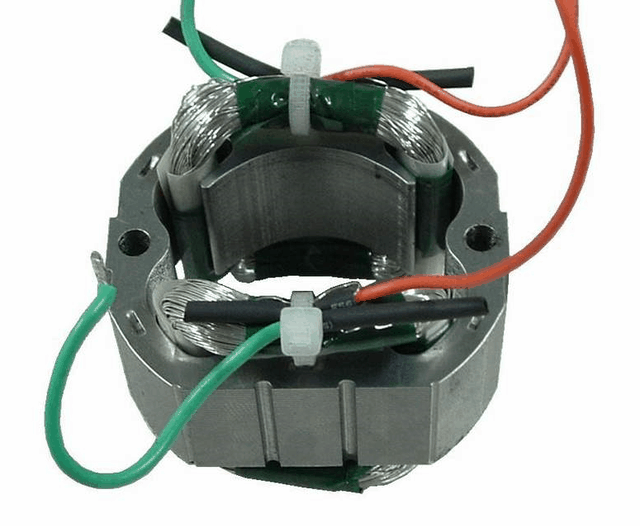

1. Impregnating paint

Dipping varnish is a kind of insulating varnish used for dipping motor windings. The wound motor winding is immersed in the varnish to fill the gaps and micropores to insulate them from each other, and after curing, a continuous film can be formed on the surface to form a hard whole. Impregnating paint can be divided into two categories: solvent paint and solvent-free paint. The quality must meet the following requirements:

1) Low viscosity, high solid content, good fluidity, easy to penetrate and fill the impregnated material.

2) Good drying performance, fast curing, strong bonding force, can withstand the centrifugal force of the motor rotation after curing.

3) Electrical properties such as heat resistance, moisture resistance, oil resistance and chemical stability meet the requirements.

4) Good compatibility with conductors and other materials.

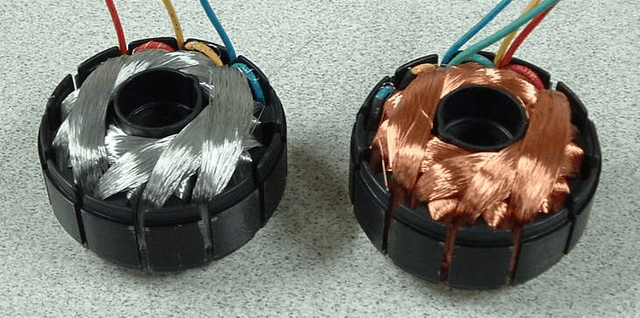

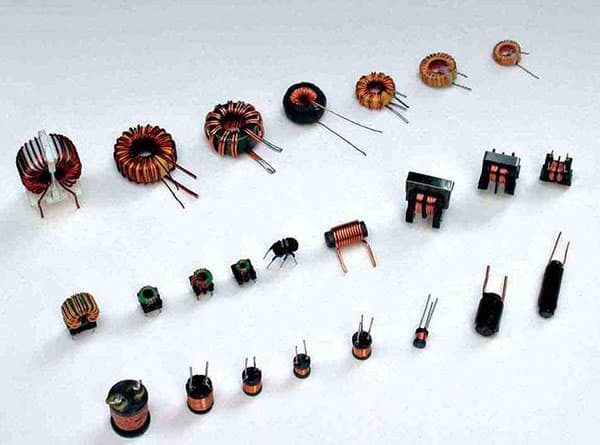

2. Enameled wire paint

Enameled wire paint is a kind of insulating paint used to coat the surface of enameled wire. In order to repair the damage caused by heat, chemical hazards and mechanical force in the process of winding and embedding the wire. The quality requirements are as follows:

1) Good coating performance, can be evenly coated.

2) The paint film has strong adhesion, smooth and tough surface, and can withstand a certain amount of friction.

3) It has good electrical properties, heat resistance and solvent resistance meet the requirements, and has no corrosive effect on conductors

3. Cover paint

Cover paint is a kind of insulating paint used to coat windings and insulating parts that have been immersed to prevent mechanical damage to the equipment insulation layer and corrosion from the atmosphere and chemicals, and to improve the surface insulation strength.

There are many types of covering paints, and different types of covering paints have different ranges of use. According to the type of resin, it is divided into three types: alkyd paint, epoxy paint and silicone paint. Among them, epoxy paint has the advantages of moisture resistance, mildew resistance, good internal drying and adhesion, and high paint film hardness. It is widely used for surface coating of motor parts in hot flash areas; silicone paint has high heat resistance and can be As a covering paint for H-class motor parts; alkyd paint is less used in motors. According to the filler, it can be divided into two types: with filler and without filler. Among them, those that do not contain fillers and pigments are called varnishes, and those that contain fillers and pigments are called enamels. The varnish has good electrical properties and is mostly used for coating the inner surface of insulating parts; while the enamel paint film has high hardness, good thermal conductivity, heat resistance and arc resistance, and is mostly used for coating the surface of windings and metal parts.

According to the drying method, it is divided into two types: air-drying paint and drying paint. Among them, the performance of drying paint is better than that of drying paint, and it is widely used. However, some large equipment and parts that are not suitable for drying are only coated with drying paint.

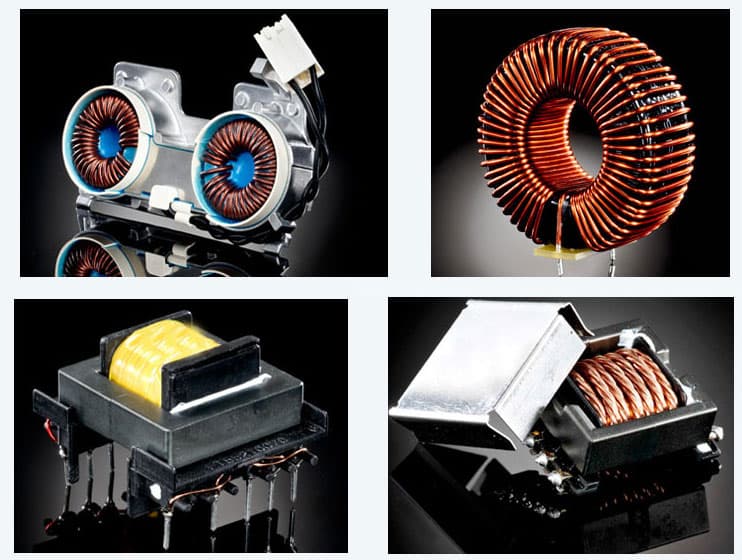

4. Silicon steel sheet paint

Silicon steel sheet paint is an insulating paint used to coat the surface of silicon steel sheets. Its function is to reduce the eddy current loss of the iron core and enhance the corrosion resistance of the silicon steel sheet. Its quality requires thin and uniform coating, strong adhesion, hard, and good electrical performance.

5. Anti-corona paint

Anti-corona paint is an insulating paint used to coat the ends of high-voltage motors windings or on the surface of asbestos tape (or glass tape). Anti-corona paint is generally made of a mixture of insulating varnish and non-metallic conductor. The quality requirements of the anti-corona paint are stable surface resistivity, strong adhesion, good wear resistance, fast drying speed, and easy storage. When coating, it should be formed once with the main insulation.

6. Surface anti-rust paint

The anti-rust paint is applied to the surface of the motor shell for anti-rust and anti-corrosion.