What are the differences between copper wire motor and aluminum wire motor?

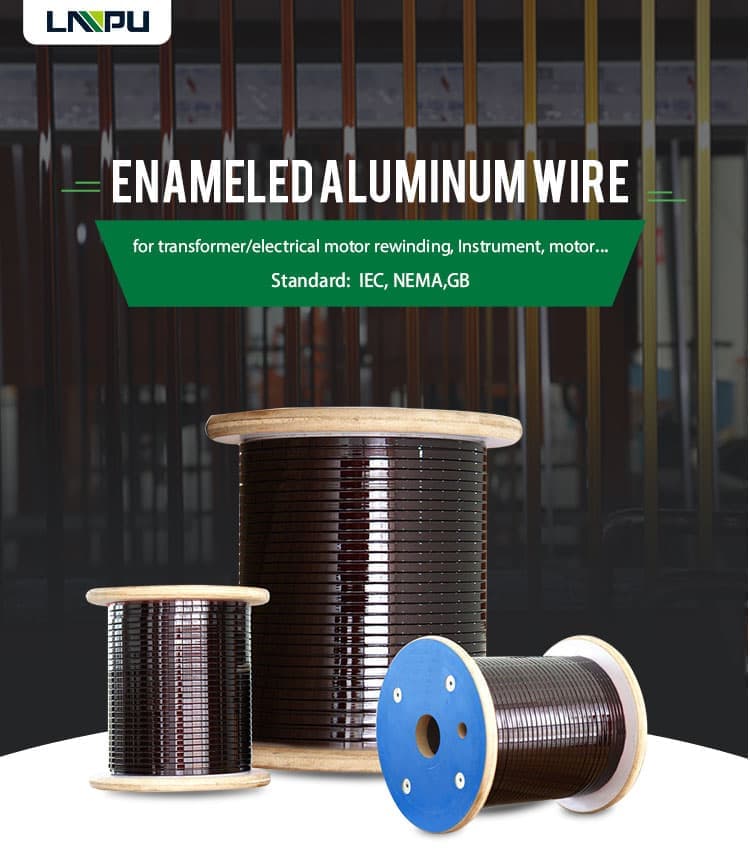

Nowadays, there are a lot of arguments that aluminum wire is used instead of copper wire in the market, and the aluminum wire motor that matches it also emerges as the times require. What are the differences between copper wire motor and aluminum wire motor? How to identify it? In fact, it is easy to distinguish from the principle of its metal.

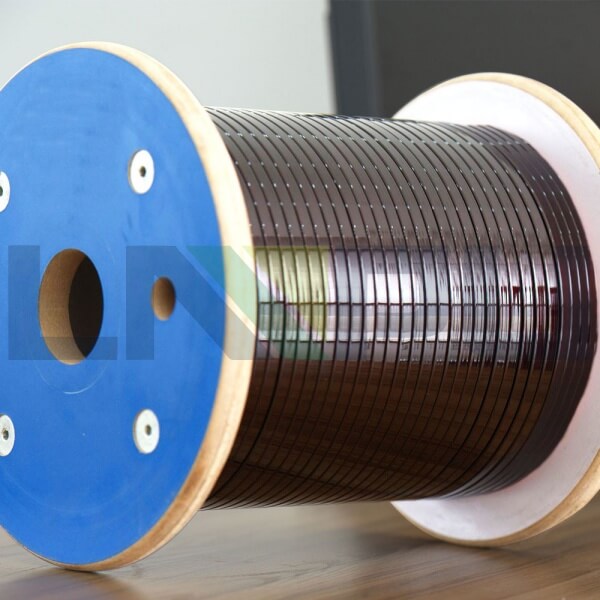

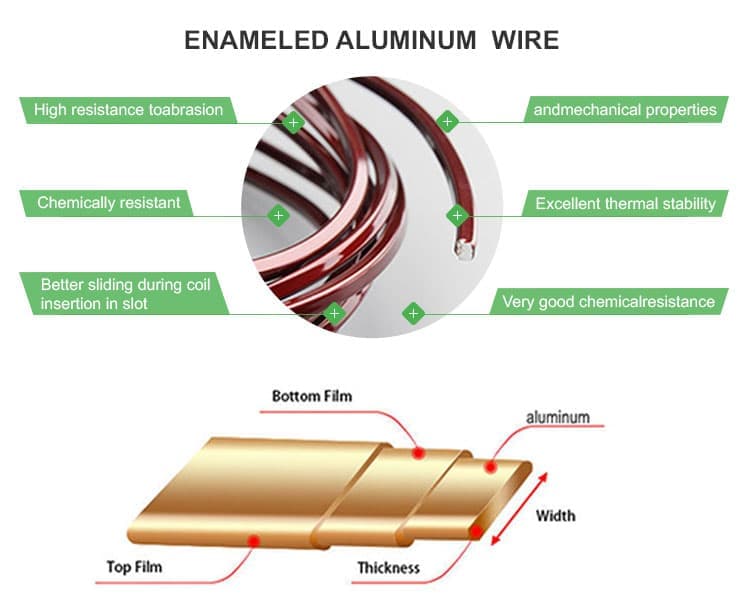

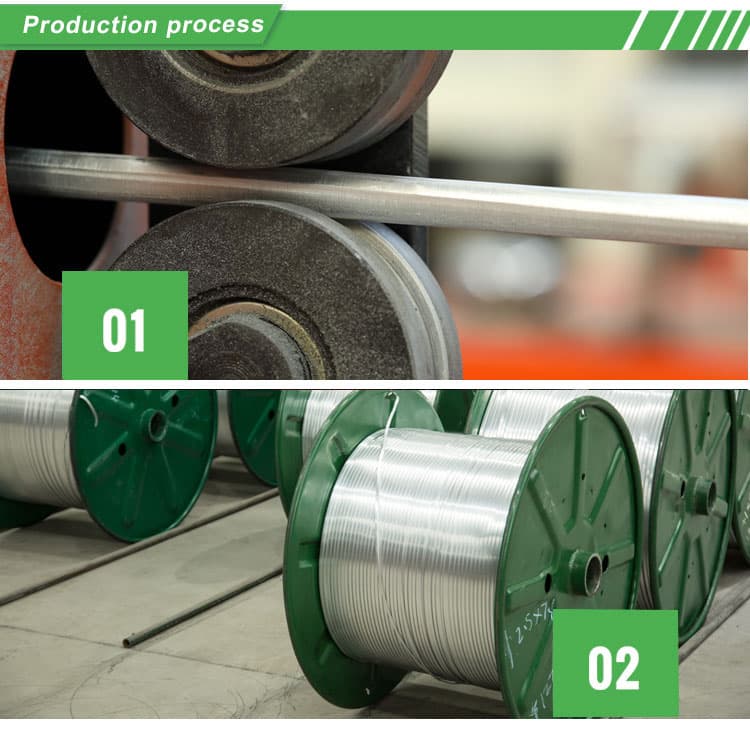

1. Because the resistance of aluminum wire with the same area is higher than that of copper wire, it is necessary to increase the cross-sectional area of aluminum wire if the same current is to be obtained in the operation of the motor.

2. Because of the different physical properties of different metals, aluminum wires can not have as good tensile properties as copper wires, and the same power motor aluminum wires are thicker than the relative.

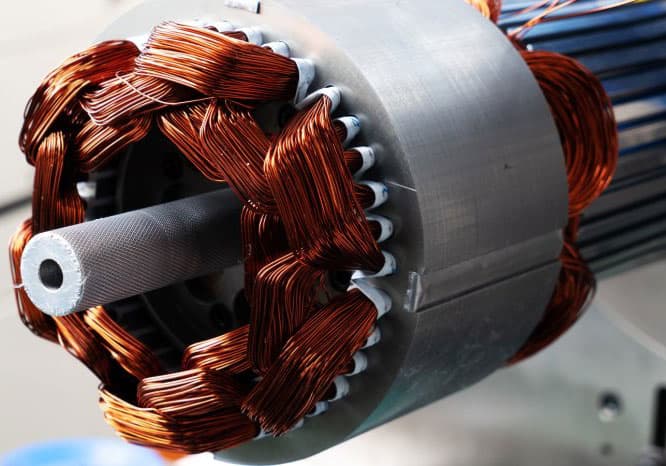

3. in order to get the same working ability, the diameter of the aluminum wire will be thickened and the winding will increase. The original design of the slot can not be satisfied enough to be fully embedded. Enlarging the groove needs to increase the outer diameter and thickness of the stator.

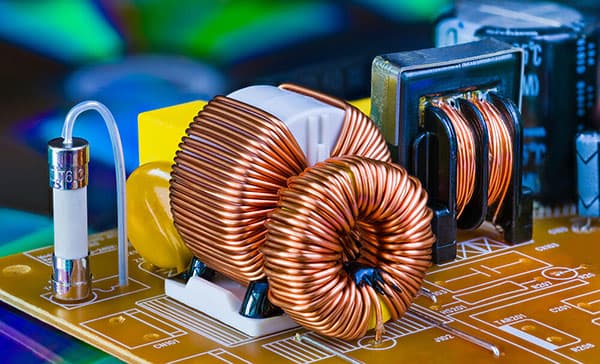

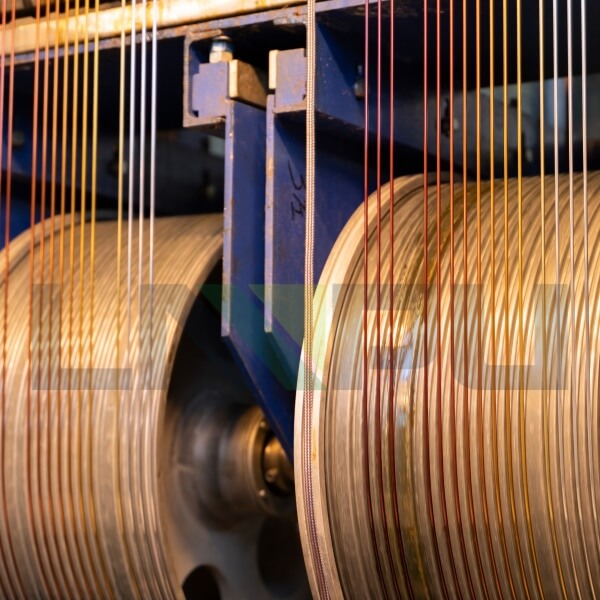

Intuitively, we can easily distinguish whether the motor is made of copper wire or aluminum wire by the appearance, and we can get satisfactory results by simple measurement.