UL Qzy-2 Class 155 28 Gauge Aluminum Enameled Copper Wire Price

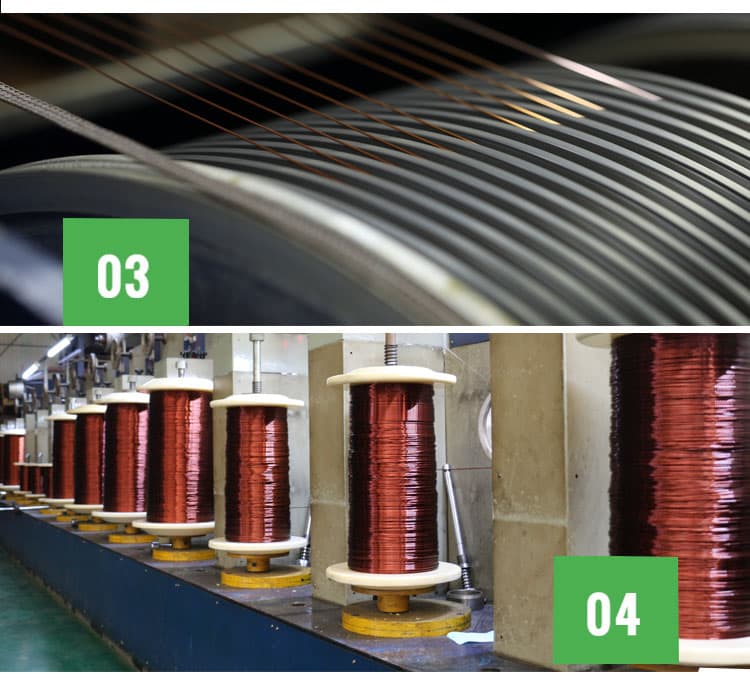

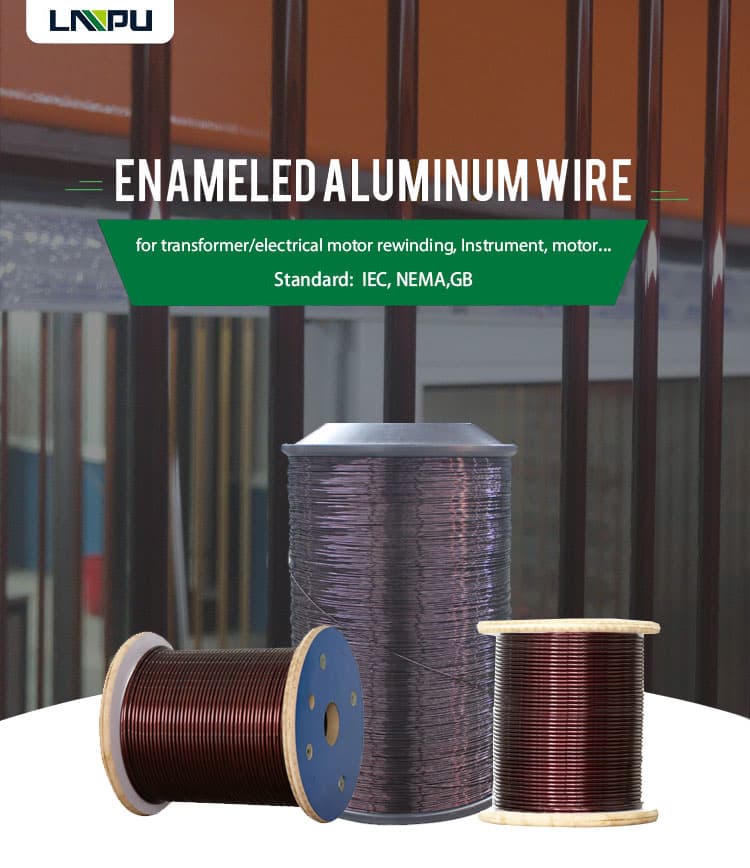

Product Name:enameled aluminum copper wire

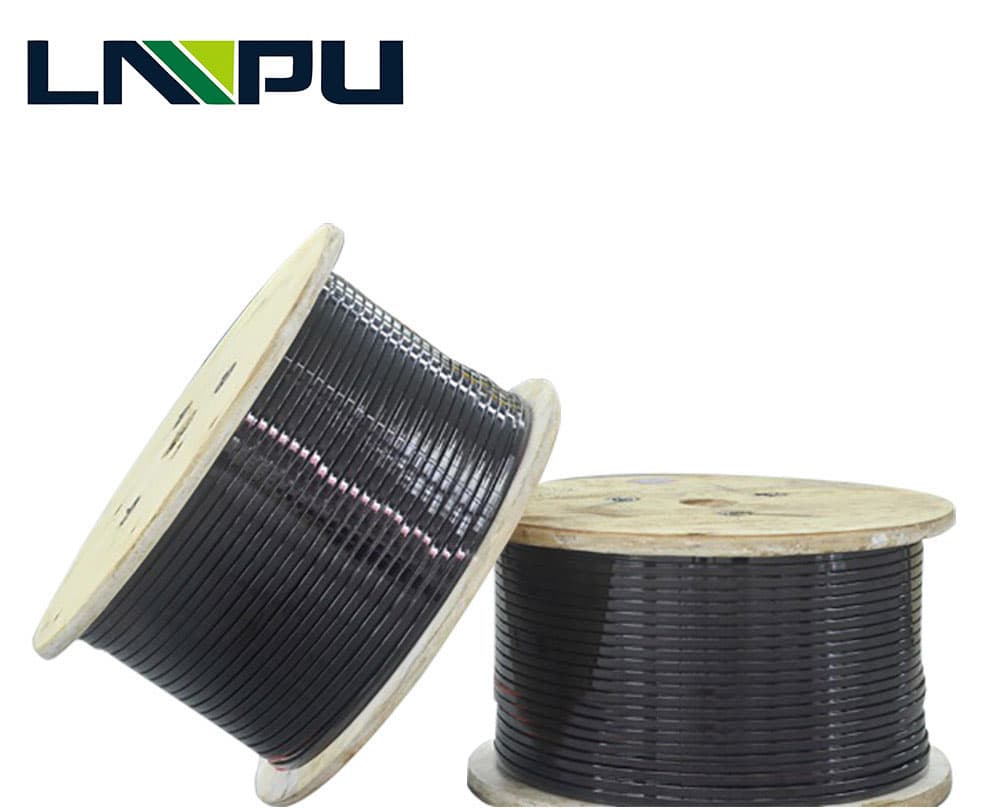

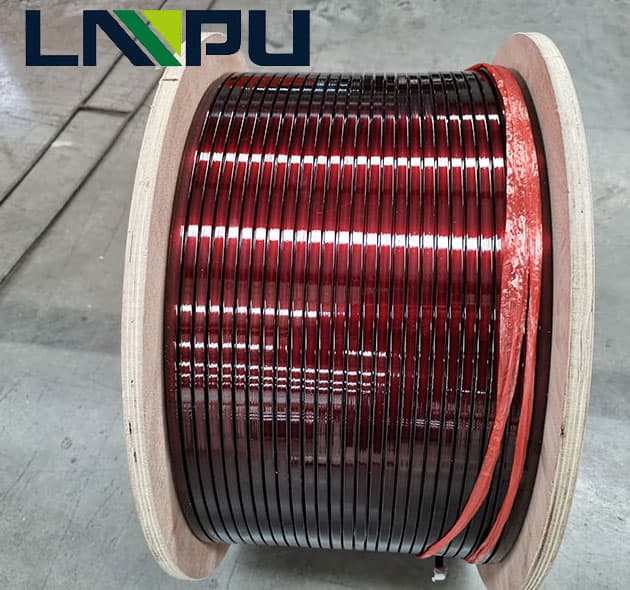

Type: flat wire

Round Dimension:28 Gauge

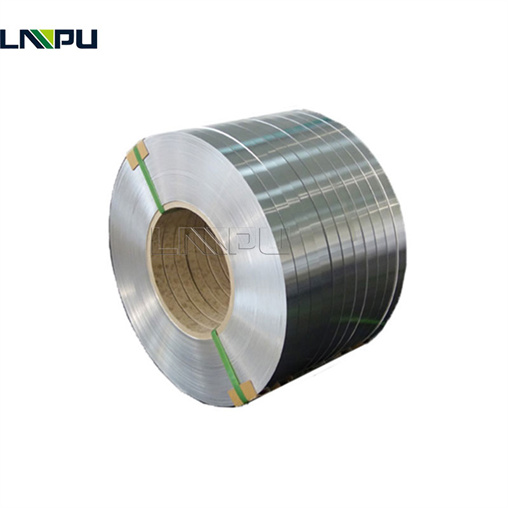

Conductor Material:Aluminum

Application:used for transformers, inductors, motors, generators, dry type transformer, Cast Resin Transformers

Certificate:UL,RoHS

Insulation Materilas: QZ

Thermal Class:155¡æ

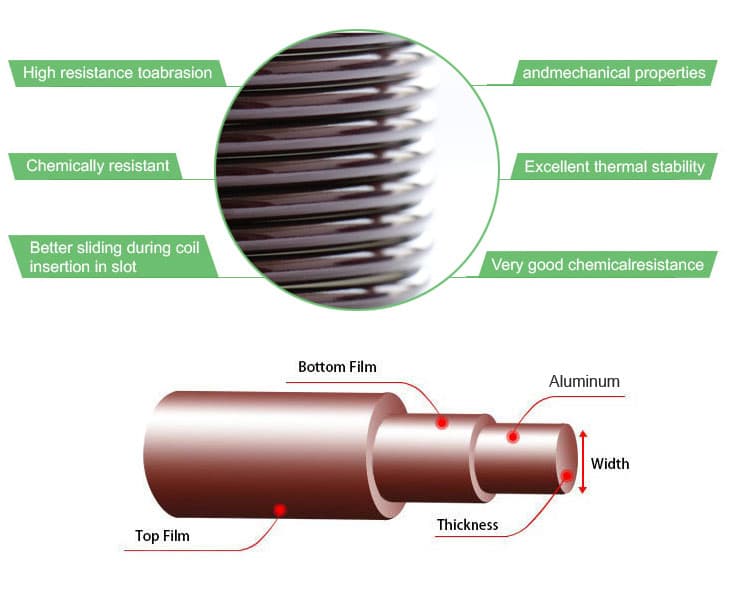

Copper-clad aluminum enameled wire is a new type of electromagnetic wire that uses copper-clad aluminum material as the inner conductor.

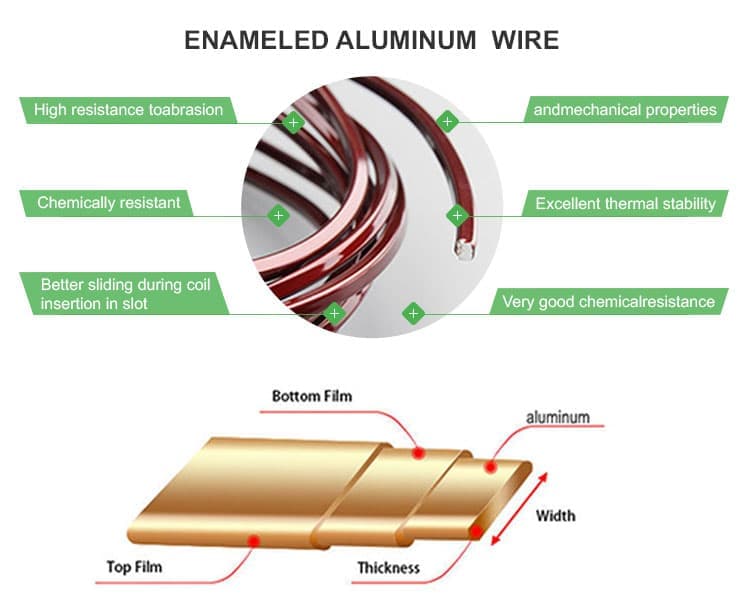

advantage

Its characteristics are between copper and aluminum, combining the excellent electrical conductivity of copper and the light weight of aluminum.

Features

1. DC resistivity: The DC resistivity of copper clad aluminum wire is about 1.45 times that of pure copper wire; when the resistance value is the same, the weight of copper clad aluminum wire is about 1/2 of that of pure copper wire.

2. Good solderability: copper-clad aluminum wire is concentrically coated with a layer of pure copper, so it has the same solderability as pure copper wire without special treatment like aluminum wire; at the same time, copper The aluminum-clad wire has a thick copper layer to ensure that the soldering performance of the product will not be affected when the paint is scraped;

3. Light weight: The density of copper-clad aluminum wire is 1/2.5 of pure copper wire of the same wire diameter, which is very effective in reducing the weight of the coil; using Shenzhou copper-clad aluminum wire to replace copper wire can save at least 30% of the cost.