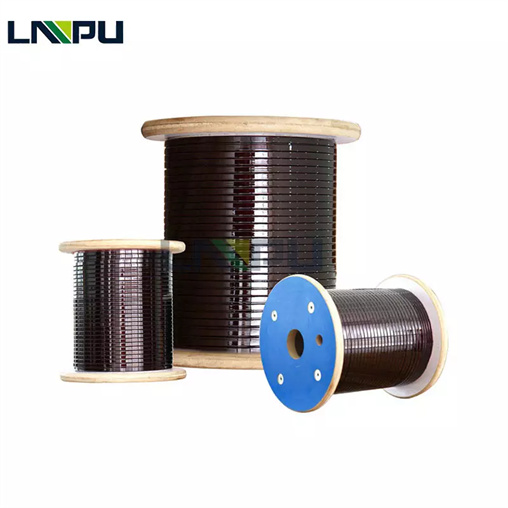

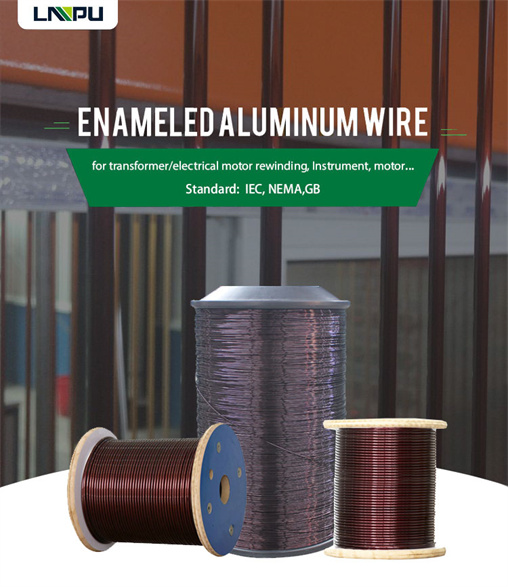

UL Qualified OEM Packing Enameled Aluminum Wire 0.7mm

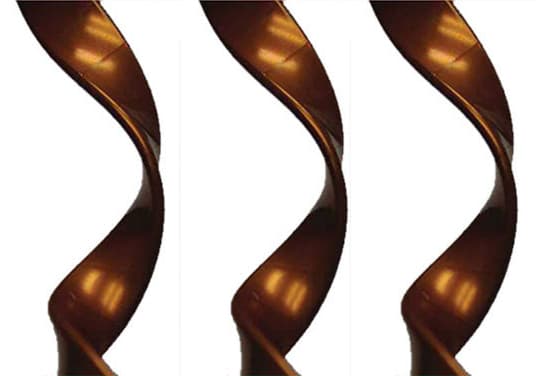

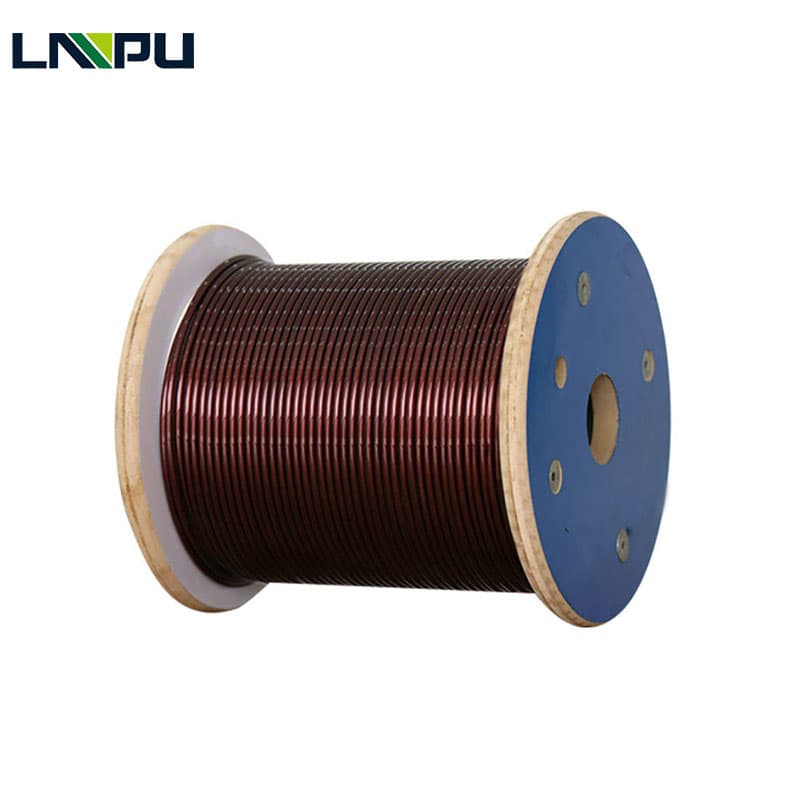

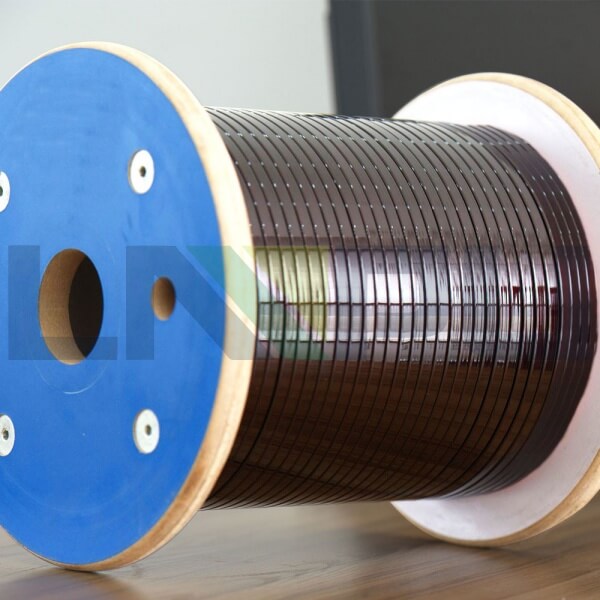

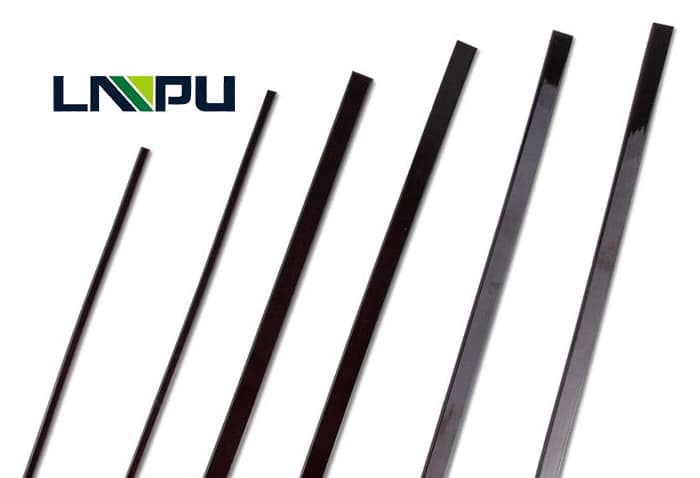

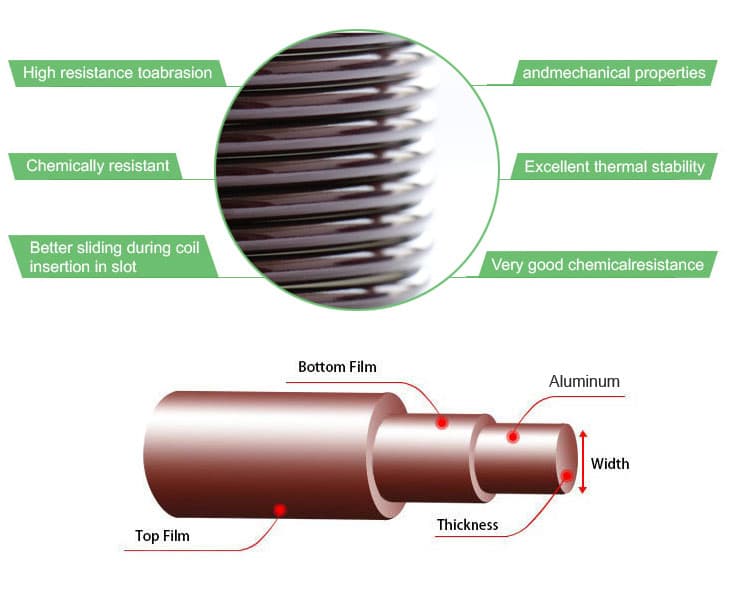

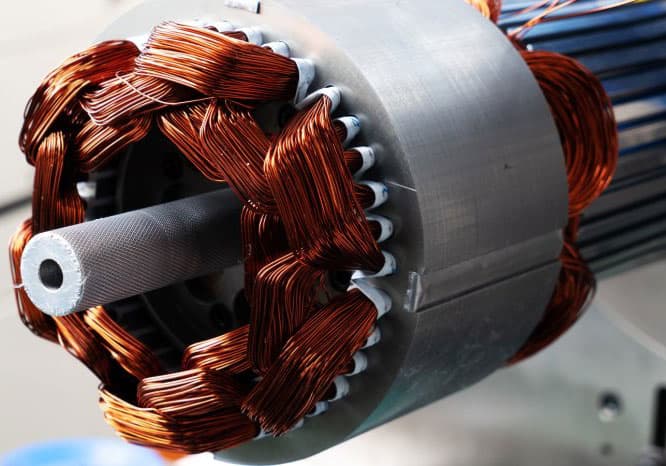

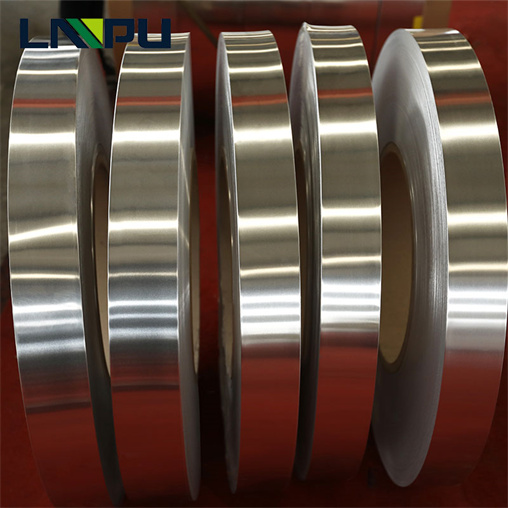

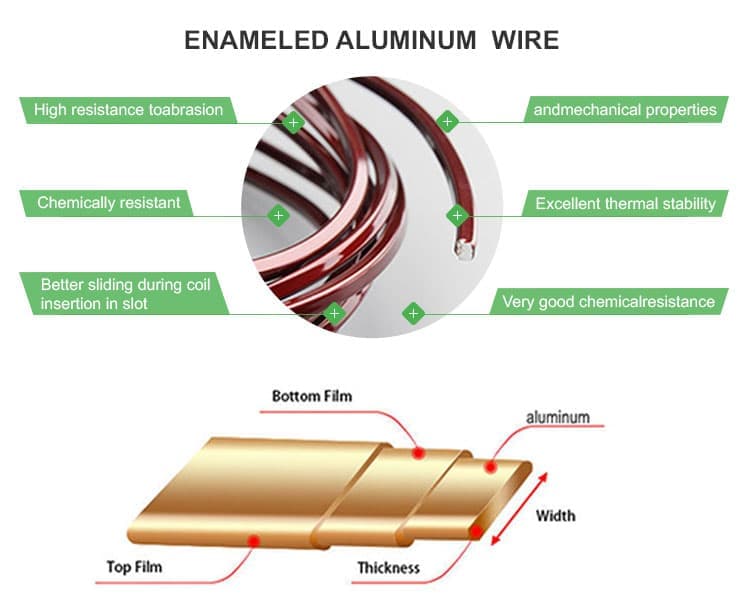

UL Qualified Oem Packing Enameled Aluminum Wire 0.7mm is a wire drawn or extruded from an oxygen-free copper rod or an electrical round aluminum rod through a certain specification die. Winding wire made of insulating varnish for many times. Mainly used in windings of transformers, motors, generators and various electrical equipment. Including 180 grade polyesterimide enameled flat aluminum wire, 200 grade polyamideimide enameled aluminum flat wire, 220 grade polyamide enameled flat aluminum wire.

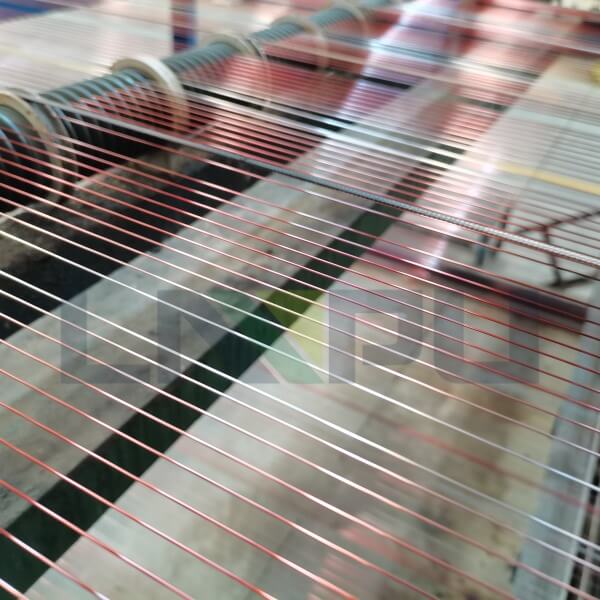

The production of aluminum enameled wire includes the following steps: 1) place the aluminum conductor on a wire drawing machine for drawing, and then draw it into an aluminum round conductor; 2) put the aluminum round conductor through the washing tank and clean it; 3) apply epoxy paint, 4) Apply high temperature polyester paint, polyester imide paint or modified polyester resin paint, 5) apply polyamide imide paint. The invention has the characteristics of simple and reasonable structure, low production cost, strong adhesion, high product yield, high temperature resistance, refrigerant resistance, good surface quality, and good thermal performance.