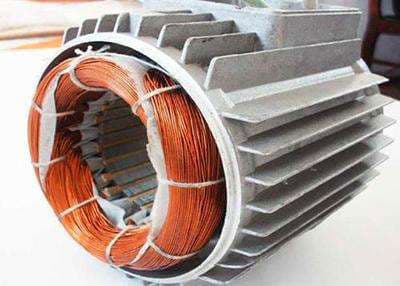

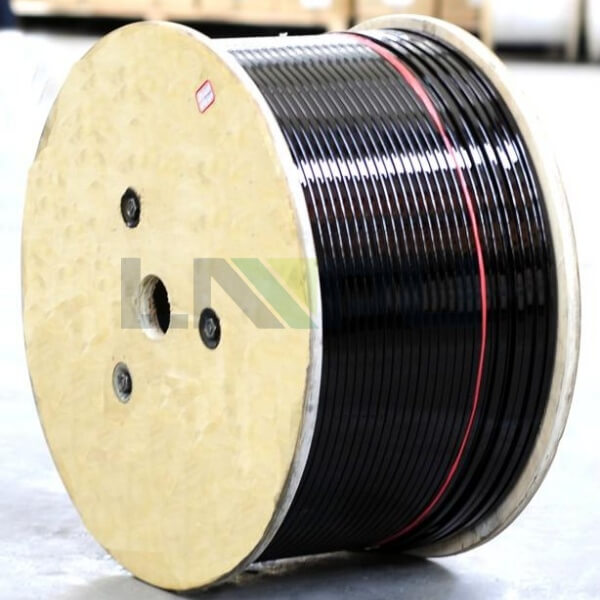

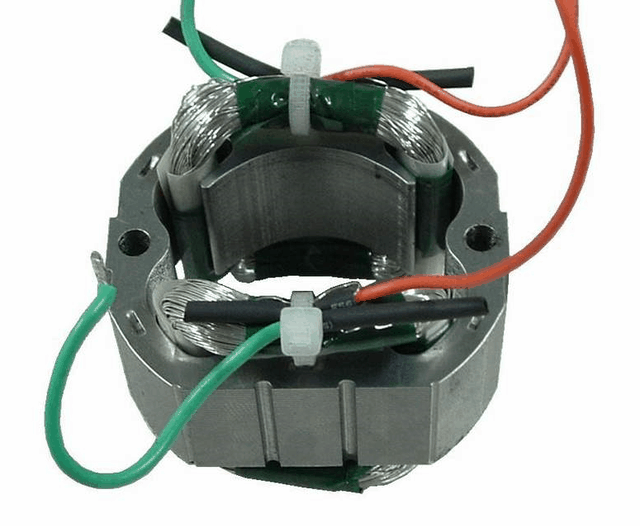

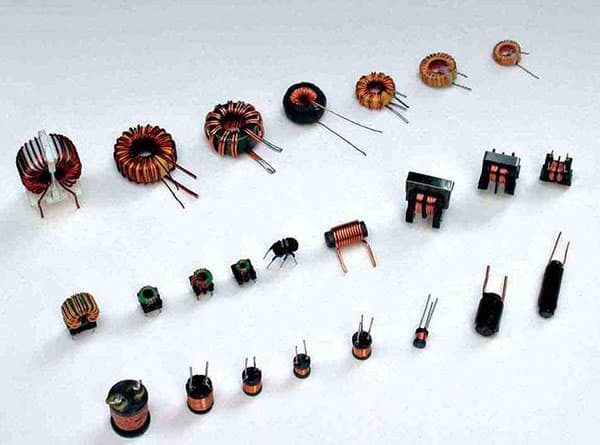

Types and scope of use of enameled wires commonly used in motors

Polyester acid/polyamide composite enameled round copper wire

1. Model: Q(ZY/X)-1/180 Q(ZY/X)-2/180

2. Temperature resistance grade: H grade (temperature index 180)

3. Production specifications: ¦µ0.20-¦µ1.50mm

4. Product implementation standard: GB 6109.10 IEC 317-22 (1990)

5. Main performance: The product has high thermal shock and small surface friction coefficient.

6. use: suitable for long-term working under high temperature motors, coil windings of instrument communication equipment, especially suitable for high-speed winding occasions.

Polyimide enameled round copper wire

1. Model: QY-1 QY-2

2. Temperature resistance grade: C grade (temperature index 220)

3. Production specifications: ¦µ0.06-¦µ2.50mm

4. Product implementation standard: GB 6109.6 IEC 317-7 (1990)

5. Main performance: The product has higher heat resistance, mechanical properties, solvent resistance, and a series of higher than polyester polyester imine.

6. use: suitable for the coil winding of the electric machine that works under the high temperature for a long time, the instrument communication equipment.

Polyester enameled round copper wire

1. Model: QZ-1/130 QZ-2/130

2. Temperature resistance grade: Class B (temperature index 130)

3. Production specifications: ¦µ0.06-¦µ2.50mm

4. Product implementation standard: GB6109.7 IEC 317-3

5. Main performance: This product has excellent mechanical properties, electrical properties, thermal shock properties and solvent resistance.

6. use: suitable for coil windings of electrical appliances, meters and telecommunications equipment.

Polyimide enameled round copper wire

1. Model: QZY-1/180 QZY-2/180

2. Temperature resistance grade: H grade (temperature index 180)

3. Production specifications: ¦µ0.06-¦µ2.50mm

4. Product implementation standard: GB 6109.5-88 IEC 317-8 (1990)

5. Main performance: The product has superior heat resistance, mechanical properties and solvent resistance.

6. use: suitable for the coil winding of motors, meters, and communication equipment that work for a long time under high temperature.

Polyurethane enameled round copper wire

1. Model: QA-1/130/150 (UEW)

2. Temperature resistance class: Class B (temperature index 130/150)

3. Production specifications: ¦µ0.018-¦µ1.50mm

4. Product implementation standard: GB 6109.4 IEC 317-4 (1970)

5. Main performance: The product has excellent direct welding performance, high frequency resistance performance, low dielectric loss under high frequency conditions, and the product can be dyed in a variety of colors for special needs.

6. use: This product is suitable for electrical machinery, instrumentation, communication equipment, and coil windings in high-frequency environments.

Polyimide/polyamideimide composite enameled round copper wire

1. Model: Q (ZY/XY)-1/200 Q (ZY/XY)-2/200

2. Temperature resistance grade: H-C grade (temperature index is 200)

3. Production specifications: ¦µ0.20-¦µ1.50mm

4. Product implementation standard: GB 6109.11-90 IEC 317-13 (1990)

5. Product performance: The product has higher thermal shock performance and smaller surface friction coefficient, and has high-quality refrigerant resistance and better solvent resistance.

6. use: especially suitable for use in motor windings of sealed refrigeration systems.