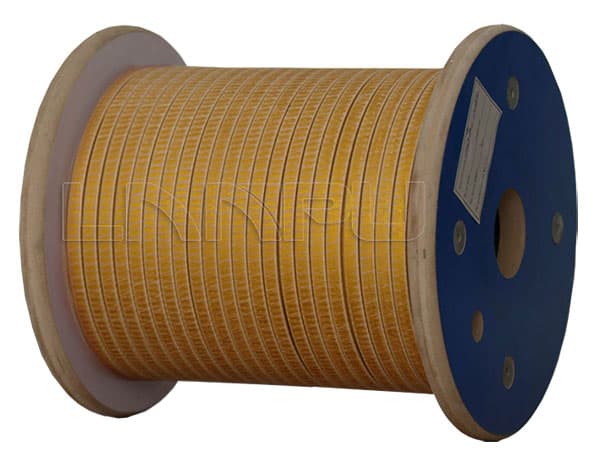

Three-layer insulated wire

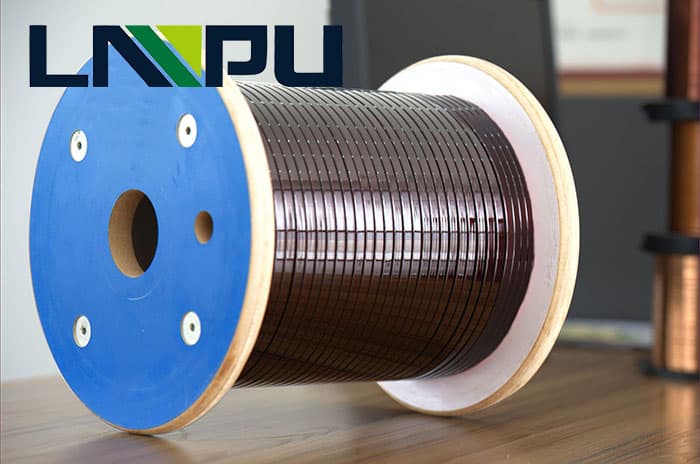

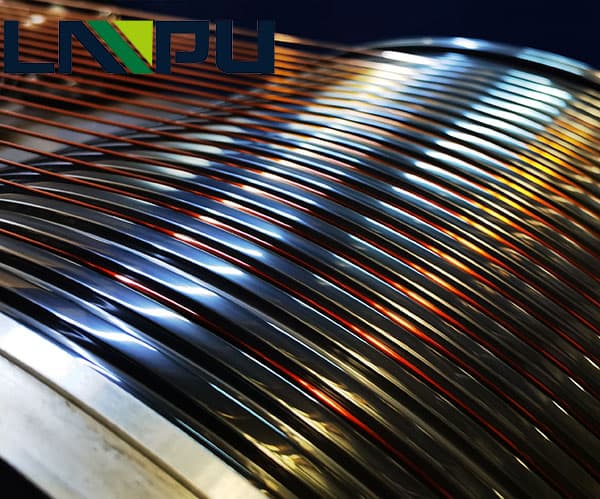

Three-layer insulated wire structure

High-frequency transformer triple-insulated wire is a high-performance insulated wire, so as the name suggests, this wire has three insulation layers with a core wire in the middle.

The first layer The first layer is golden yellow polyamine film, its thickness is a few microns, but it can withstand 3KV pulse high voltage

The second layer is a spray paint coating with high insulation,

The third layer is a transparent glass fiber layer. The total thickness of the insulating layer is only 20-100um. Its advantage is high insulation strength, and any two layers can withstand a safe voltage of 3000V AC, and the current density is large.

How to use general three-layer insulated wire

The storage conditions for the three-layer insulated wire are an ambient temperature of -25 to 30 degrees Celsius, a relative humidity of 5% to 75%, and a shelf life of one year. It is forbidden to store three-layer insulated wires under high temperature, high humidity, direct sunlight, and dust environment. For the three-layer insulated wire that has exceeded the storage period, it must be tested again for insulation breakdown voltage, withstand voltage, and windability before it can be used.

Pay attention to the following precautions for winding: The three-layer insulated wire relies on the film to strengthen the insulation. If the film is severely deformed or damaged due to mechanical or thermal stress, the safety standards cannot be guaranteed; there must be no burrs on the transformer frame, the corners of the contact wires should be smooth (chamfered), and the inner diameter of the outlet mouth should be 2~3 times the outer diameter of the wire; the end of the cut wire is very sharp, do not get close to the wire film.

Special equipment such as three-layer insulated wire stripping machine, adjustable stripping machine and other special equipment are required to peel the film. Its characteristic is that it will peel off while melting the film, so the wire will not be damaged. If an ordinary wire stripping machine is used to strip the insulation film, the wire may be thinned or even broken.