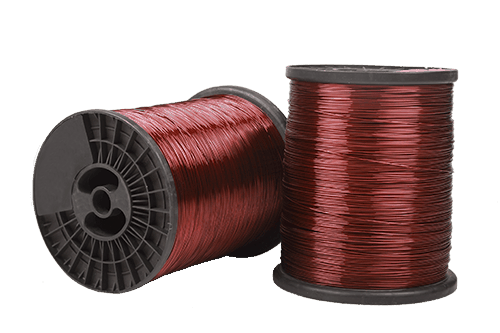

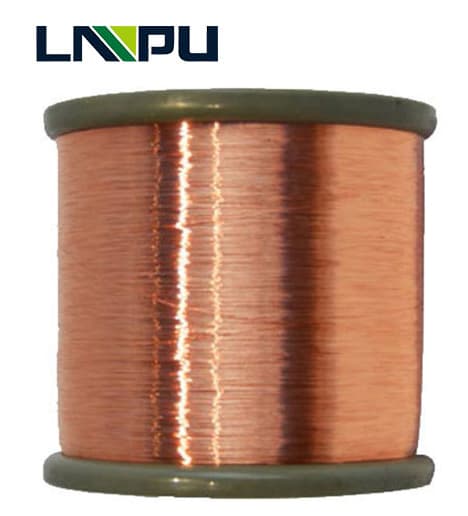

Thermal Class 105 / 133 / 155 Grade Enameled Wire

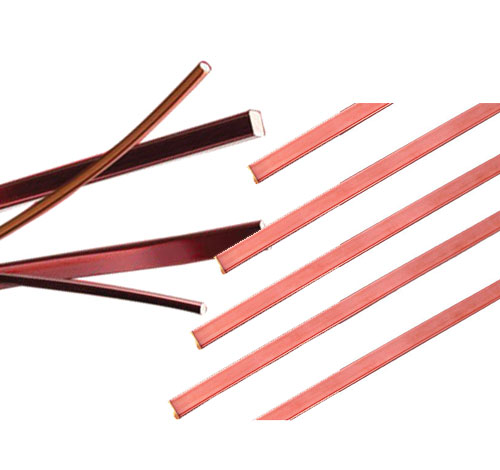

Thermal Class 105 / 133 / 155 Grade Enameled Wire includes

Polyethylene formaldehyde enameled copper wire (PVF)

Polyester enameled copper wire (PEW)

Polyurethane enameled copper wire (UEW).

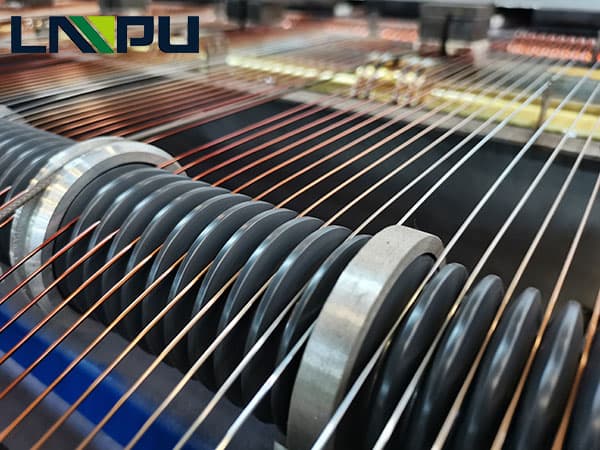

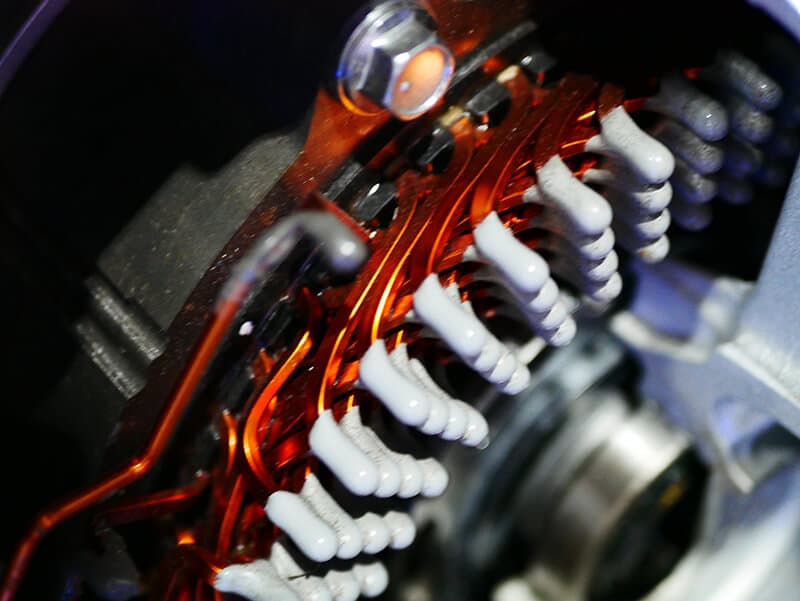

Application: Normally used for Oil-filled transformers, motors, micro motors, transformers and high frequency coils, relays, magnetized coils

1. Polyethylene formaldehyde enameled copper wire (PVF)

Temperature resistance rating: 105 degrees

Insulation description: The insulating layer of PVF is composed of polyvinyl acetal and phenolic resin. It is one of the first synthetic materials used in the manufacture of enameled wire insulating paint, and has been widely used in film insulation since its introduction.

characteristic:

(A) PVF has good winding properties, adhesion, abrasion resistance and solvent resistance.

(B) Compatible with most varnishes or impregnated synthetic materials.

(C) Compatible with transformer oil.

Applications: Oil-filled transformers, motors, etc.

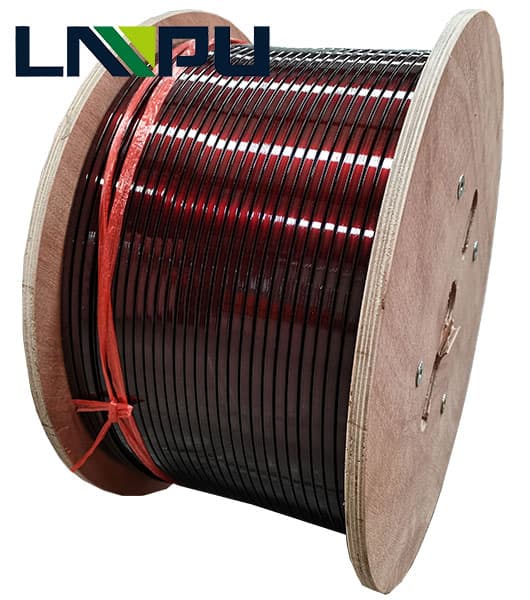

2. Polyester enameled copper wire (PEW)

Extreme temperature resistance: 155 degrees

Insulation description: The insulation layer of PEW is polyester fiber resin, the temperature grade is 155 degrees, and it has good temperature stability and insulation properties.

characteristic:

(A) It has good anti-cracking properties, abrasion resistance, chemical resistance and temperature stability.

(B) Its physical properties, such as windability, abrasion resistance and adhesion, are better than PVF wire.

Applications: motors, micro motors, transformers.

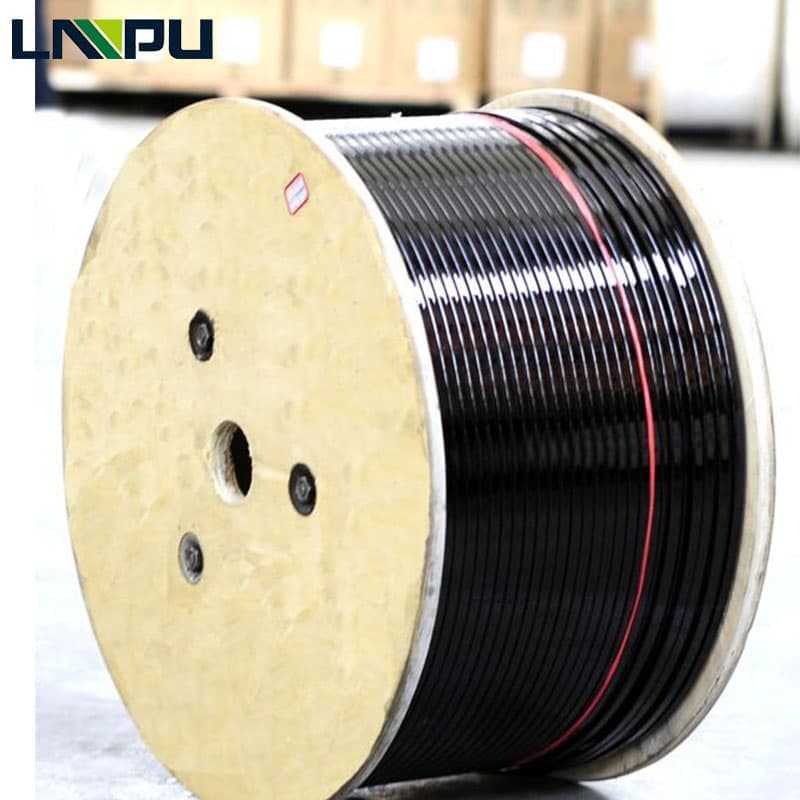

3. Polyurethane enameled copper wire (UEW)

Temperature resistance and so on: 130/155 degrees

Insulation description: UEW’s insulation layer has good direct solderability at 360-400 degrees, and is widely used in coils and motor windings.

characteristic:

(A) It has good direct weldability and can avoid the action of peeling off the film during the winding process, which effectively improves work efficiency.

(B) At high frequencies, it has good ¡®Q¡¯ value (quality factor) characteristics.

(C) It has good adhesion and winding properties.

(D) Generally, it is impregnated with the solvent and hardener used in Van Lishui, which has good solvent resistance.

Application range: high frequency coils and transformers, relays, magnetized coils