The hazards of pinholes on enameled wires

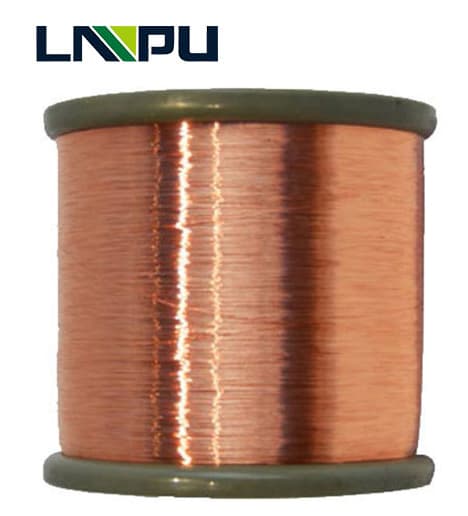

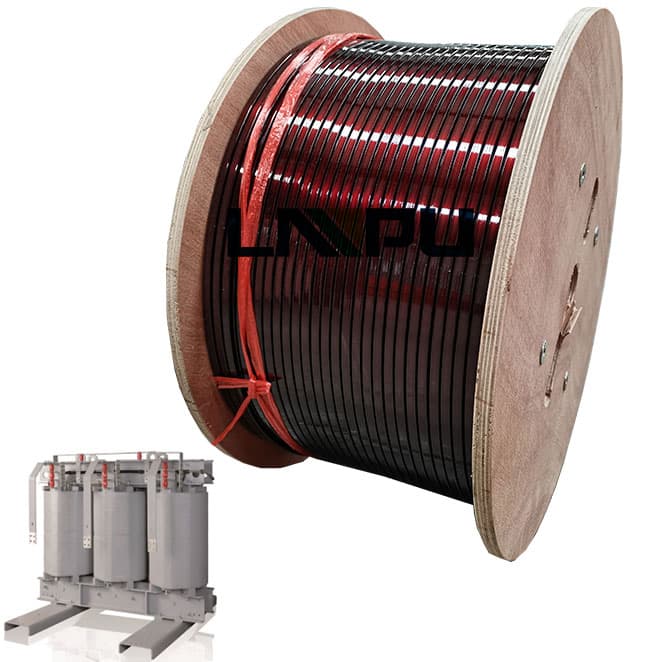

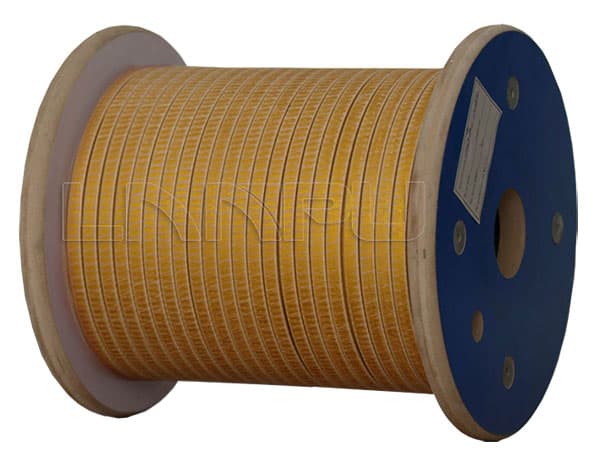

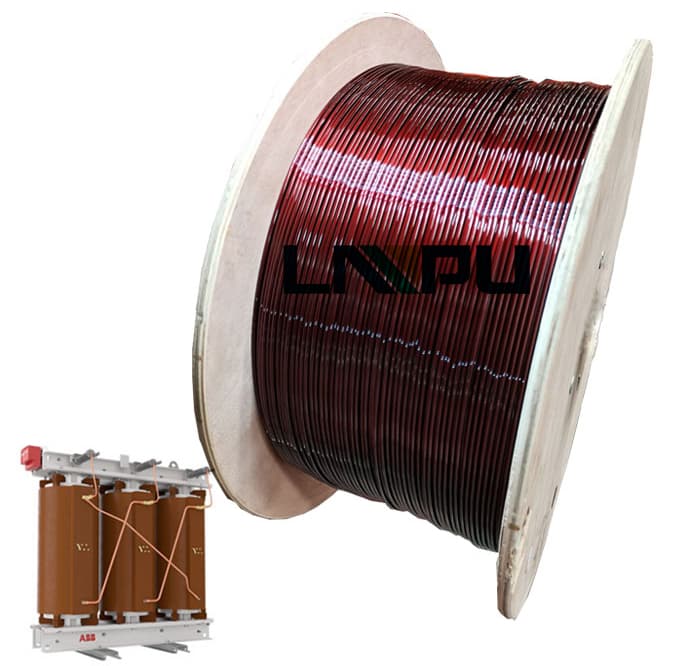

Enameled wire is the most widely used electromagnetic wire in the production of low-voltage products. A key performance requirement of this electromagnetic wire is the continuity of the paint film, which is to check the number of pinholes in the paint film under a certain length. When checking the number of pinholes, use a professional paint film continuity tester. The fewer the number of pinholes, the better the paint film integrity of the magnet wire.

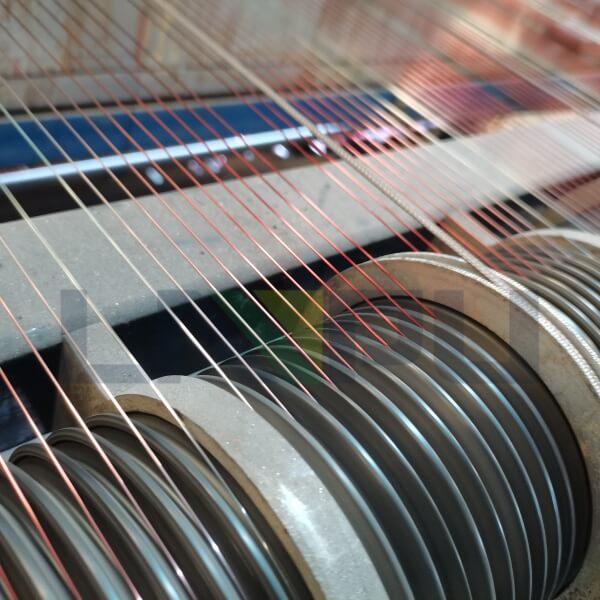

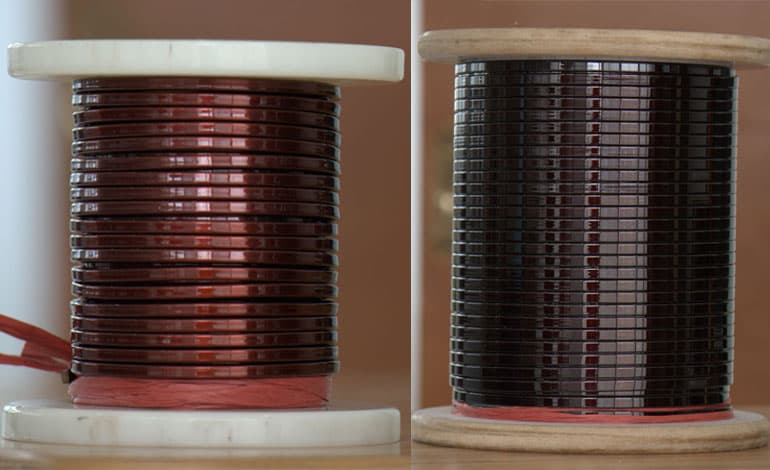

The detection of pinhole defects is based on the principle of high-pressure leakage. The electromagnetic wire is in contact with the concave wheel applied with high voltage in a semi-enveloped manner. When the thickness of the paint film is insufficient or there are serious bare copper defects, the instrument will record the specific Number of defects.

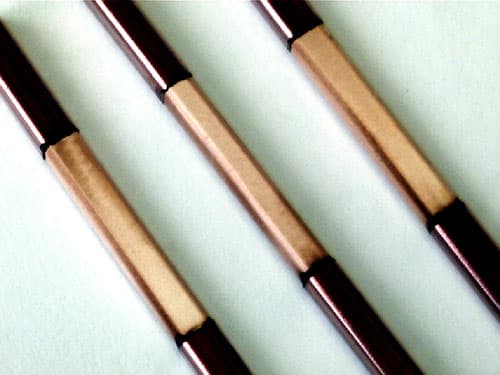

The reasons for this defect can basically be attributed to two categories. One is the unsuitability of copper materials, that is, the molding core has more burrs, which may be caused by the raw material itself or the drawing process; the other may be It is caused by uneven painting, impurities in the paint, the quality of the paint itself, and drying after painting.

As a motor manufacturer, you should pay special attention to this performance, because this kind of defect can easily lead to inter-turn faults in the motor, which seriously affects the service life of the motor.