The enameled wire has a quality problem with multiple ends

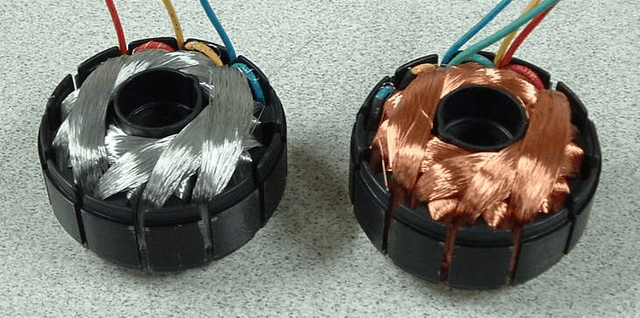

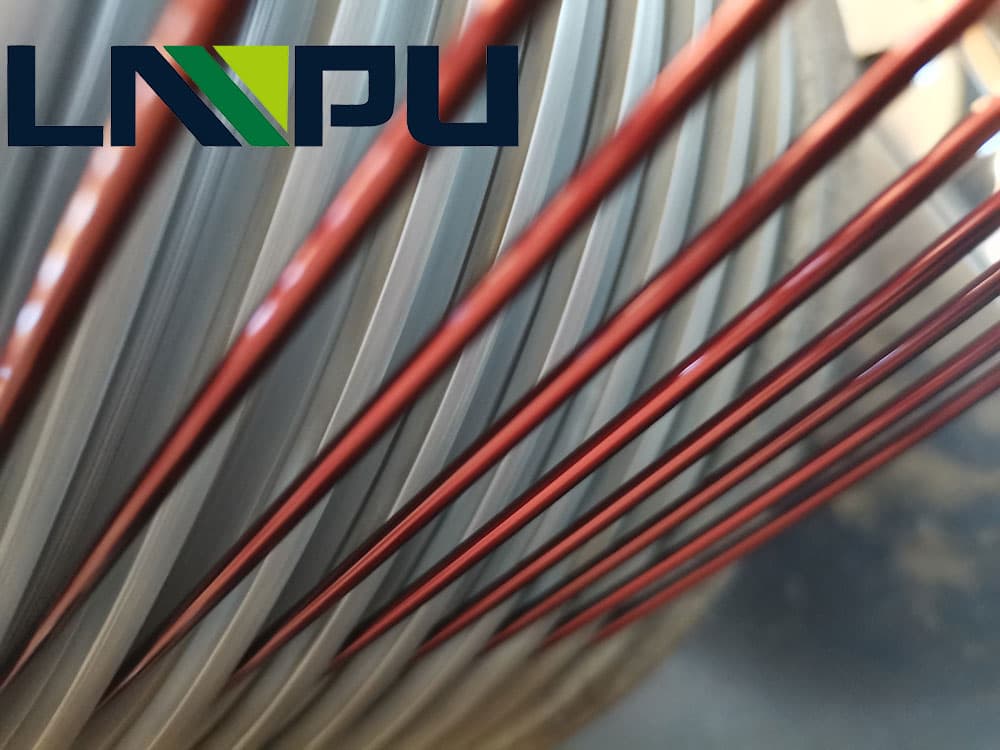

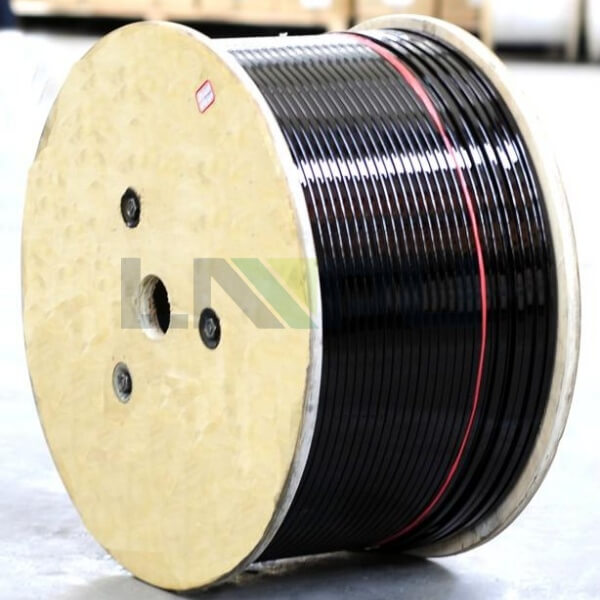

It is often seen in the electronics industry that when returning goods, the quality reason is “multi-threaded”. This is really wrong to the enameled wire factory. Because the current production machines of enameled wire are single-end pay-off and single-end take-up, there is no multi-end.

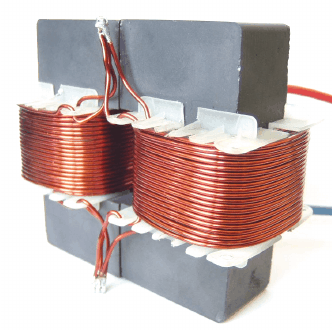

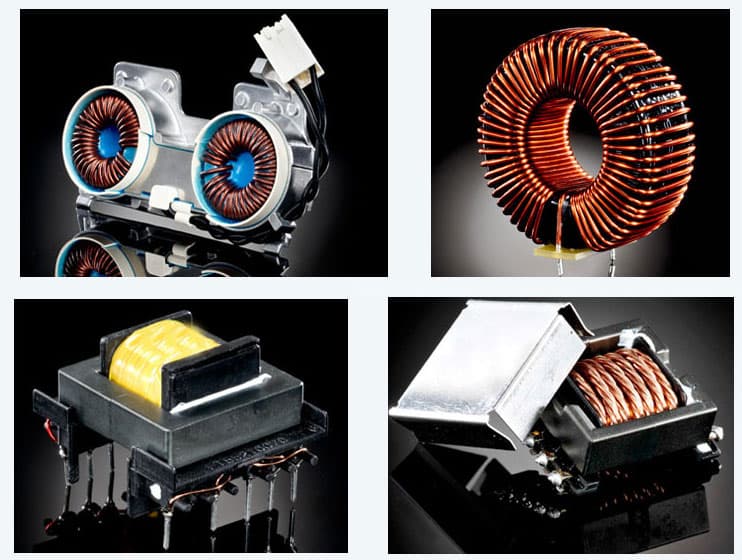

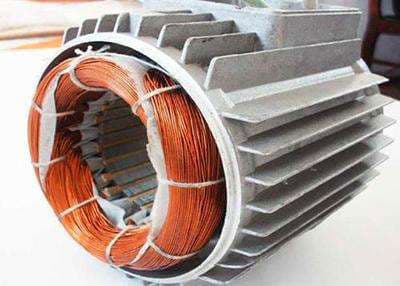

In fact, most of the “multi-threads” are produced by users-electronics factories. During the laying-out process, the machine should be stopped every few minutes to replace the transformer skeleton. When the machine is stopped, the pay-off tension of some machines is not in place. Due to inertia, the upper coil collapses and presses the lower thread. When the machine is turned on again, the thread is pressed and the thread breaks. The initial chaotic line was formed.

If the thread cannot be used normally after the thread is broken, the spool must be removed from the winding machine for processing. Of course you can continue to use the processed one. However, in the process of dealing with the chaotic thread, if one thread is accidentally broken, it becomes three heads, and two threads are broken, it becomes five heads… In this way, the axis cannot be processed. The manufacturing process is returned to the warehouse, and the warehouse is returned to the production plant in the name of multiple threads. This is the process of “multi-thread” production and return.

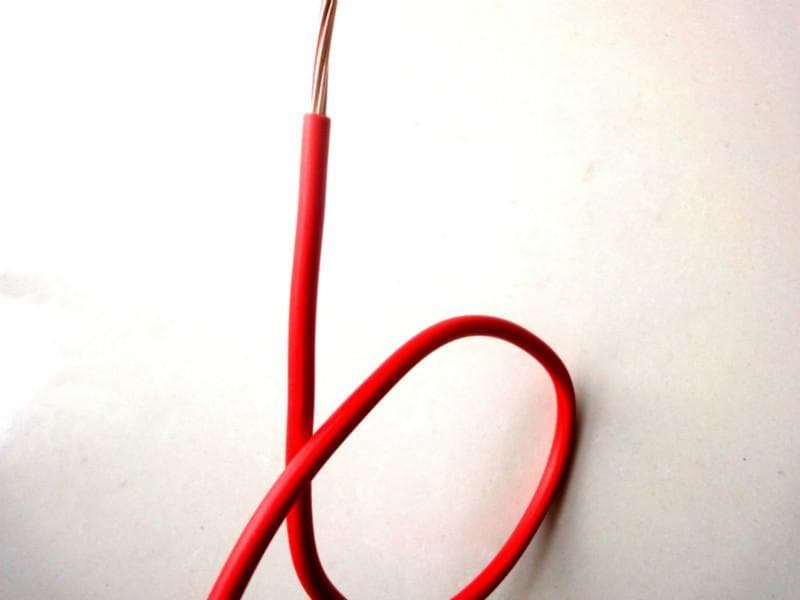

In fact, multiple thread ends are easy to handle: use a sharp blade to pick and break a few turns of thread, grab the broken thread and pull it up. Until a head appears.

Note: ¢Ù The method of reversing the thread can be handled in the same way.

¢Ú The customer’s line breaking and disorder during the laying-out process may also be related to the product line not being closely related — when the product line is being loosened.

¢Û In some production plants, enameled wire segments are added to the light shaft to reduce costs, which can also be regarded as a special multi-thread head. In the 1974 national standard, it is allowed to add a line segment, but it must be marked. In most enameled wire factories, there is only one line segment on one axis.

¢ÜIn the enameled wire production process, two or more wires in the oven are combined together, which is the actual waste wire. If the operator forgets to remove the waste wire from the machine, it can also be regarded as a special multi-thread end. But this probability is about one in a million.

¢Ý Multi-threads with unchanged weight are mainly caused by the thread not being tightly tied when leaving the factory, and the thread breaking and pressing the thread during transportation.