The Difference Between Vibrating Motor Enameled Aluminum Wire And Enameled Copper Wire

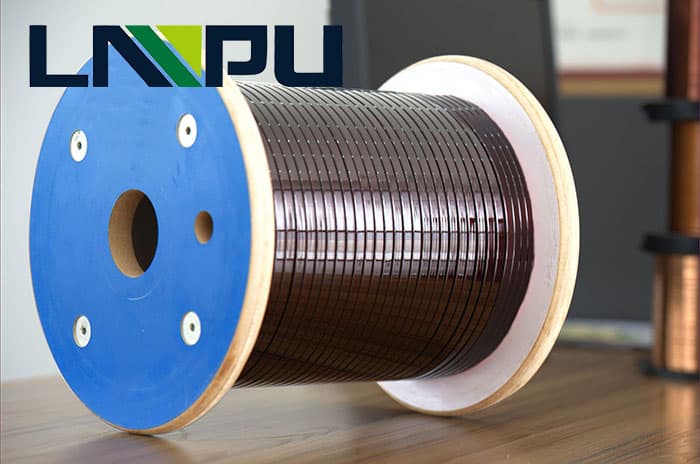

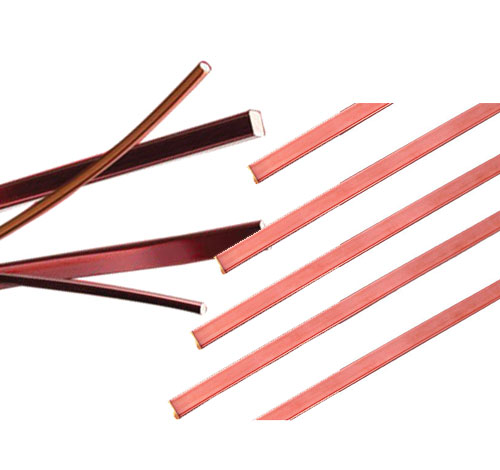

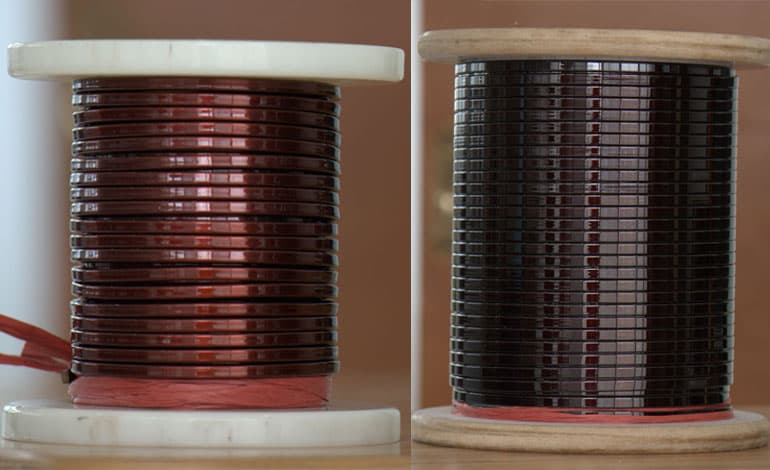

The difference between enameled aluminum wire and enameled copper wire of vibration motor: the resistivity of copper wire is 0.017, and the resistivity of aluminum wire is 0.028. The cross-sectional ratio of copper wire and aluminum wire interchange is 0.79:1, and six square copper wires are equivalent to ten square aluminum wires. The diameter of the aluminum wire is thicker than that of the copper wire, and the same aluminum wire of the stator slot will not fit.

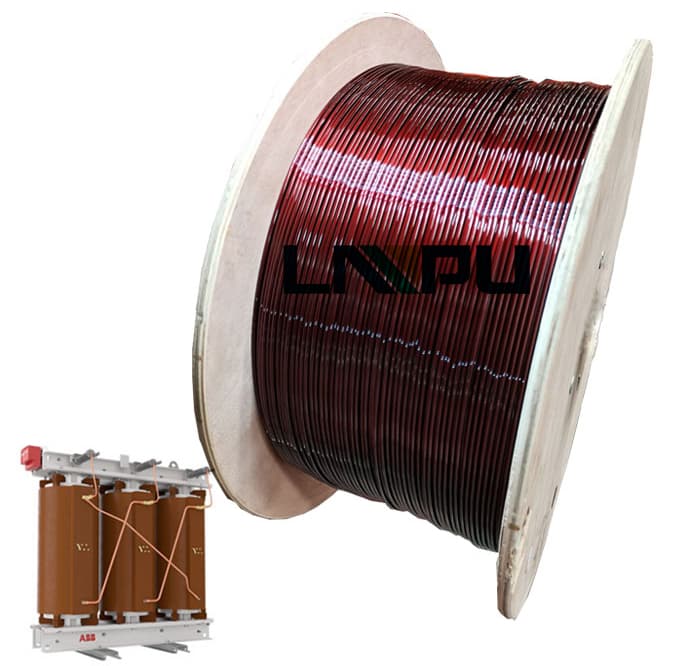

The amount of current passed per unit area is also different. Copper wires can pass 5-8A per square millimeter, while aluminum wires are much less, about 3-5A.

In addition to the different cut-off amounts and materials of copper and aluminum wires, the main differences are: aluminum wires are lighter in weight, relatively cheaper, and have poorer mechanical strength. Aluminum wires are extremely susceptible to oxidation at the end of the wire, and after the end of the wire is oxidized Temperature rise and poor contact will occur, which is a frequent point of failure (power failure or disconnection). In addition, aluminum is not easy to weld, has low strength, low melting point, is easy to oxidize, rises in temperature, and consumes a lot.

According to: p=I*I*R, it is known that under the same current situation, the large resistance R consumes more power, so the aluminum wire is not as good as the copper wire.

Why do some vibrating motor manufacturers using copper wire use aluminum wire? As we all know, the price of aluminum is much lower than that of copper. Some vibration motor manufacturers use enameled aluminum wire as the winding material of the vibration motor in order to reduce costs. Obviously, the use of enameled aluminum money will cause many problems in the vibration motor: if aluminum is used instead of copper, in order to maintain the same efficiency, it is necessary to enlarge the stator slot shape, increase the cross-sectional area of ??the wire, and increase the length of the core, which will lead to the deterioration of the silicon steel sheet. Increase in dosage. Because the resistivity of aluminum is higher than that of copper, the stator loss of aluminum wire motors will increase greatly. If the volume of the vibration motor is kept constant, the efficiency of the motor will inevitably decrease, and the temperature will increase, which is serious. It will affect the service life of the vibration motor and seriously damage the interests of customers.