The application trend of enameled copper clad aluminum wire in the motor industry

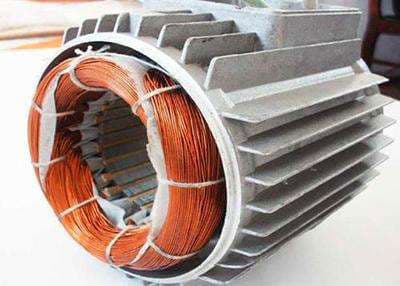

The conductive properties of pure metal materials are ranked. Among them, the material with the best conductivity is silver (Ag), followed by copper (Cu), after copper, it is gold (Au), and then aluminum (Al). Analyzed from the application level, silver and gold are precious metals and cannot be used in large quantities when the unit price is too high. Copper is the best choice for moderate price and good performance, and it is the main force used in the current industry. It is widely used in electrical related industries, such as enameled coils used in motors, whose internal conductors are made of copper. Although aluminum is the cheapest material among them, the difference in its electrical conductivity is an unacceptable conductor material in applications where high efficiency is the premise.

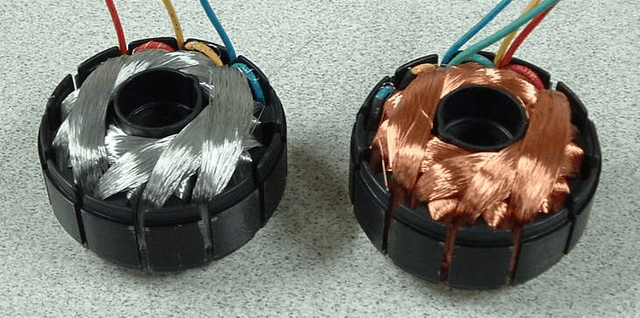

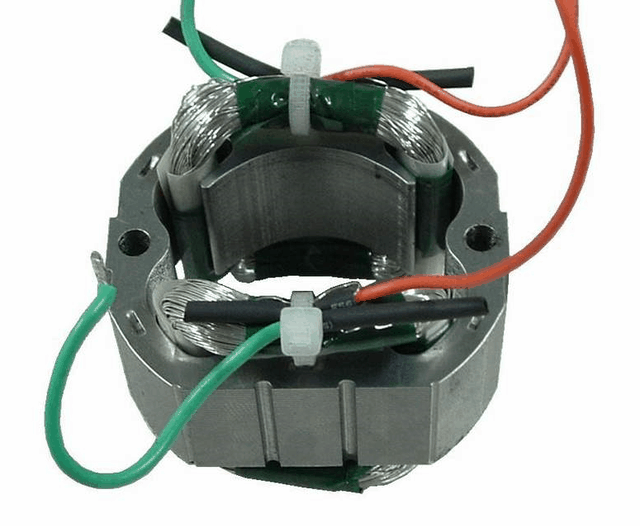

The biggest difference between enameled aluminum wire and enameled copper wire for single-phase induction motors is also caused by the poor conductivity of aluminum. Therefore, the wire diameter of enameled copper wire has to be reduced to 0.12. The same motor specifications as enameled aluminum wire can be reached by about mm. On the contrary, if the single-phase induction motor that originally used enameled copper wire is changed to enameled aluminum wire, the wire diameter must be somewhat larger. To increase, it can reach the specifications required by the original motor. Therefore, the motor will need more space to accommodate the increased wire diameter, but this more space is often the most difficult to provide among the motors.

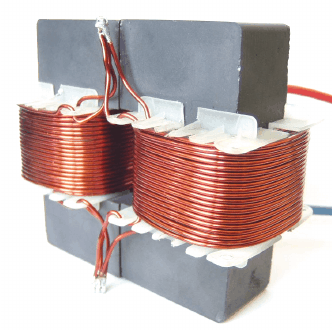

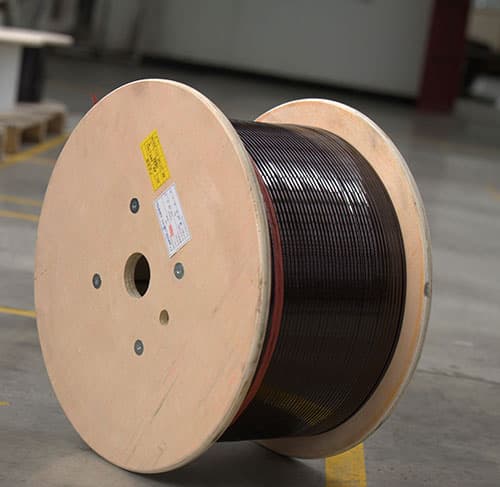

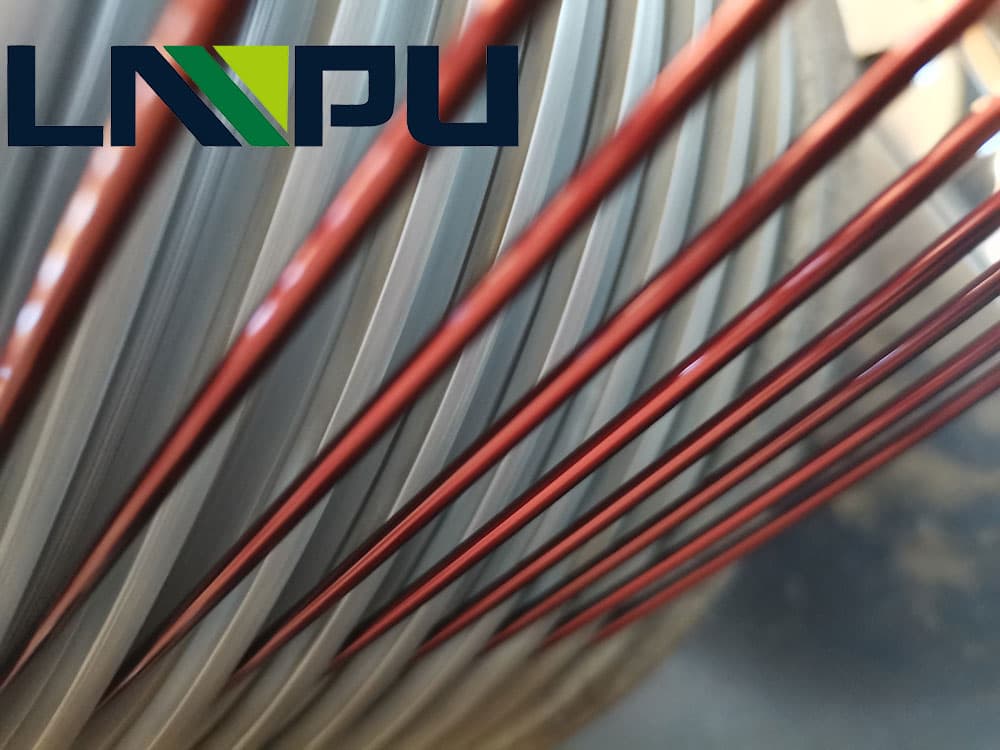

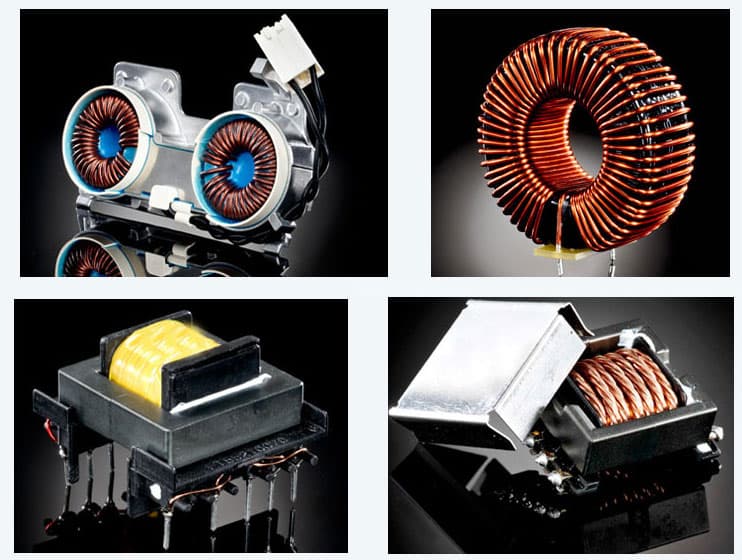

Aluminum has poor welding performance and poor ductility and other material properties that are not easy to use. Therefore, a layer of copper is coated on the periphery of aluminum to effectively improve these defects and characteristics, resulting in composite copper-clad aluminum This kind of composite copper-clad aluminum wire is the core material of coaxial cable and radio frequency cable. Because it has better carrier performance than pure copper wire, it is widely used in electrical connectors, core components of home appliances, coils, and network signals. In the field of high-tech technology such as mark.

With the rapid development of cable television networks and the Internet, the demand for copper-clad aluminum wires has increased day by day, and the skyrocketing international copper prices in recent years has caused the demand for alternative wires for copper wires to grow multiple times. The price of copper is always higher than 3 times that of aluminum. Under the incentive of higher prices, copper-clad aluminum wire has also begun to emerge. Its weight is only 40% of copper, and the purchase cost is only 60% of copper. The use of copper-clad aluminum wire can save nearly 30% of the cost compared with traditional copper wire. This amazing advantage has caused many fields that were not suitable for copper-clad aluminum wire to start studying how to use this composite wire.

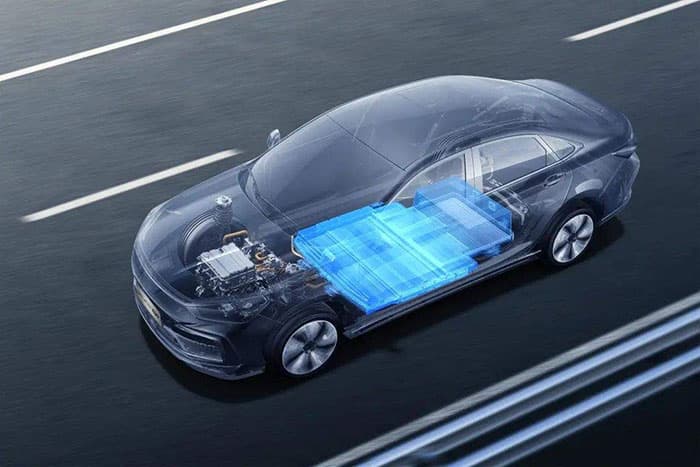

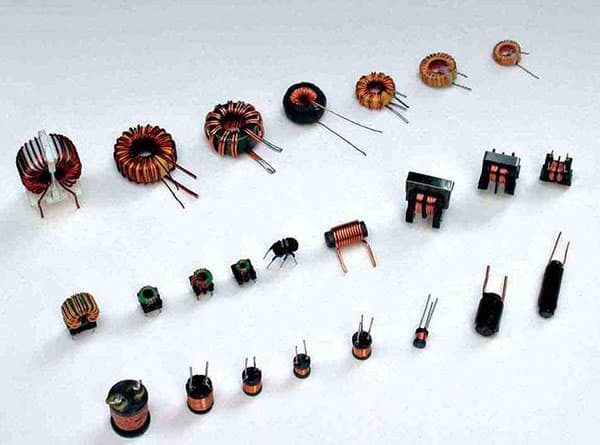

The motor is a mechanism that converts electrical energy into kinetic energy, and its power supply efficiency directly affects the mechanical kinetic energy. Therefore, under the consideration of the efficiency of energy conversion and the economic cost, enameled copper wire has become the best choice among motors. For the sake of cost reduction alone, choosing enameled aluminum wire to wind the motor coil will not only reduce the material cost, but also reduce the overall weight of the motor at the same time, which can greatly improve the competitive advantage of the product. However, the introduction and use of enameled aluminum wire in motors has not been welcomed as expected. This is not only due to the impact of poor conductivity, but also the tensile strength of aluminum wire is insufficient in terms of production, causing the coil to fail. Solid and easy to disconnect. Due to the difference in the material of enameled aluminum wire spot welding, special solder is needed for processing. There have been cases of detachment at the welding point due to poor spot welding and the skin effect of the current, and the thermal conductivity of the aluminum wire is also It is worse than copper wire, which will make the temperature rise and high temperature inside the motor. Various reasons make the motor gradually reject the enameled aluminum wire.

Conclusion

The motor¡¯s incompatibility for enameled aluminum wire, enameled copper clad aluminum wire has become a new generation of high-quality choice. Its inner layer has the characteristics of aluminum, which greatly reduces the weight and cost, while the outer copper part keeps In order to improve the strength and spot weldability of the copper wire, this composite performance has greatly improved the acceptance of use, and the copper-clad aluminum wire has also been formally introduced into the motor industry.