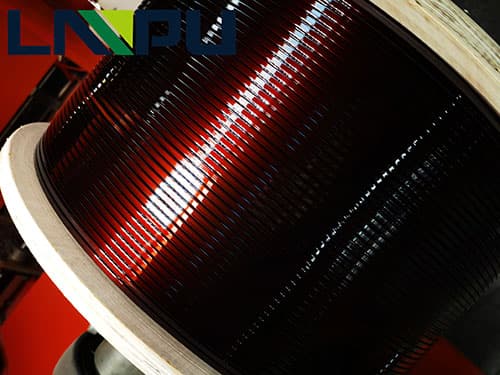

Spooling Enameled wire on the wooden roll

The purpose of collecting and arranging the wire is to continuously, tightly and evenly wind the enameled wire onto the spool. The wire take-up mechanism is required to drive smoothly, with low noise, proper tension and regular wire arrangement. In the quality problems of enameled wire, the proportion of returns due to poor wire collection and arranging is very large, which is mainly manifested in the large wire tension, the wire diameter is thinned or the wire reel burst; the wire tension is small, and the wire reel is broken. Loose lines cause chaotic lines, and uneven lines cause chaotic lines. Although most of these problems are caused by improper operation, it is necessary to take necessary measures in the process to bring convenience to the operators.

The take-up tension is very important, which is mainly controlled by the operator’s hand feeling. According to experience, some data are provided as follows: the thick wire of about 1.0mm is about 10% of the non-stretching tension, the middle wire is about 15% of the non-stretching tension, the thin wire is about 20% of the non-stretching tension, and the fine wire is about the non-stretching tension. 25% of it.

It is very important to reasonably determine the ratio of the winding speed and the winding speed. Small cable spacing can easily cause uneven lines on the spool. If the line spacing is too small, the next few turns of the wire will be pressed against the first few turns when the wire is taken up, and it will suddenly collapse when it reaches a certain height, making the next loop of wire Pressed under the previous circle of the line, the user will break the line when using it, which will affect the use. The wire spacing is too large, the first batch of wires and the second batch of wires are arranged in a cross shape, the enameled wire on the wire reel has many gaps, the capacity of the wire reel is reduced, and the appearance of the enameled wire is messy. Generally, the center distance between the wires of the wire reel with a smaller core should be three times the wire diameter; for the coil with a larger diameter, the center distance between the wires should be three to five times the wire diameter. The reference value of line speed ratio is 1:1.7~2.

Empirical formula T = ¦Ð(R+r)¡ÁL/2V¡ÁD¡Á1000

T¡ªone-way travel time of the cable (min) R¡ªdiameter of the side plate of the spool (mm)

r¡ªSpool diameter (mm) L¡ªSpool opening distance (mm)

V¡ªLine speed (m/min) D¡ªOuter diameter of enameled wire (mm)