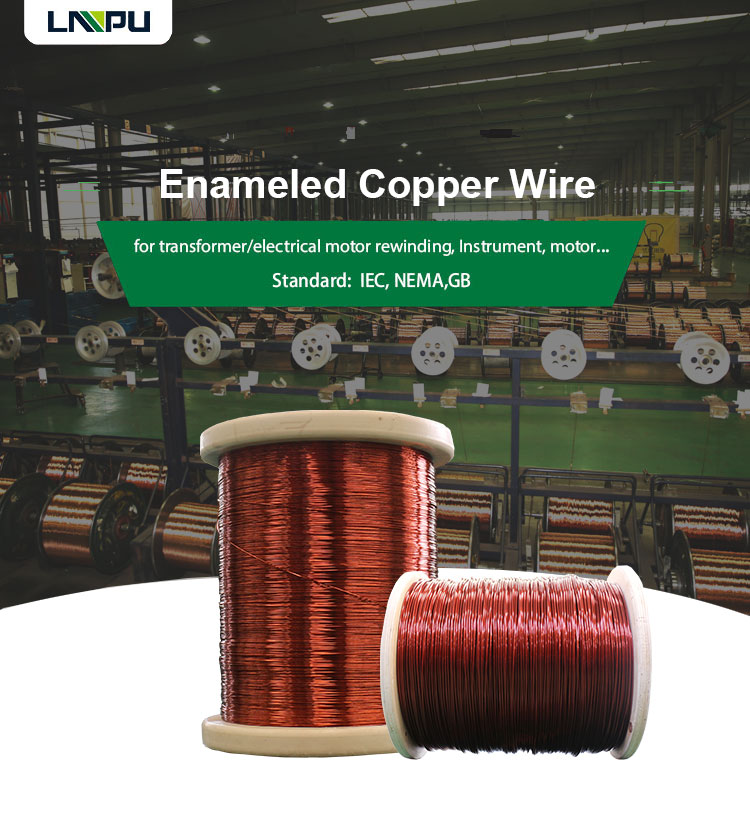

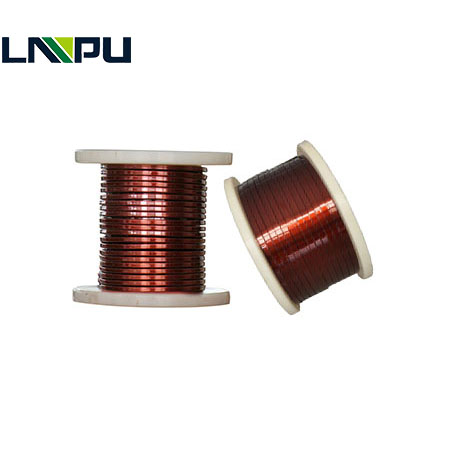

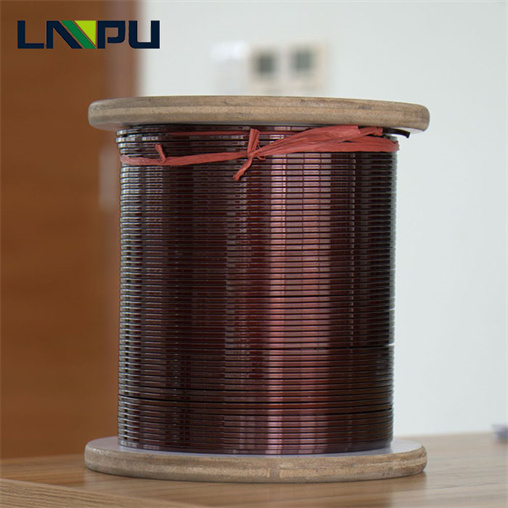

Special Copper Winding Magnet Wire Used For Automotive Sensors

Special Copper Winding Magnet Wire Used For Automotive Sensors

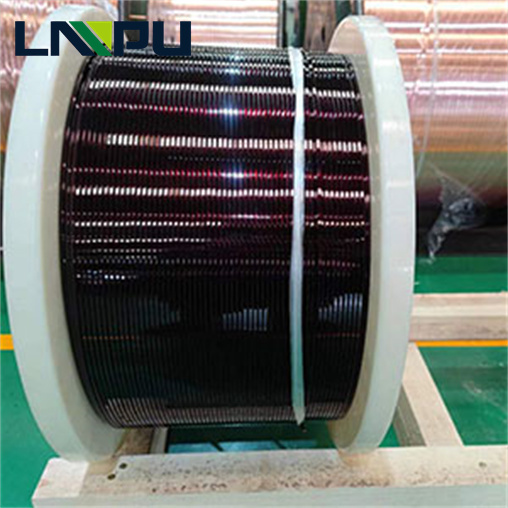

Stranded enameled copper wire (LITZ)

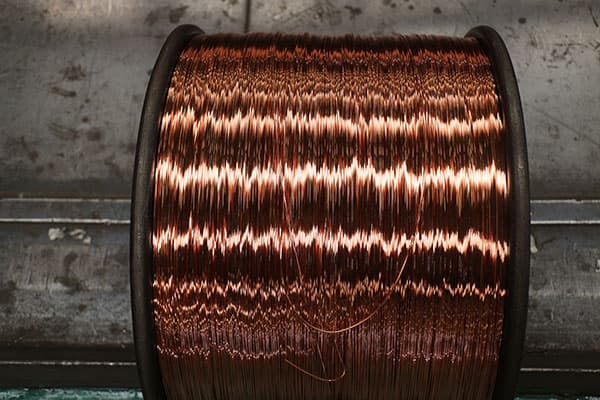

Self-fusing enameled copper wire (R*-SB)

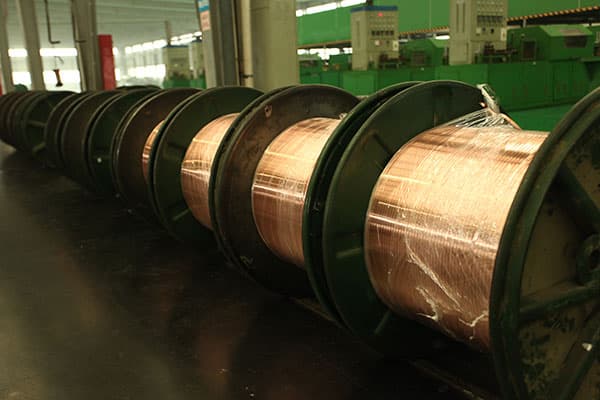

Polyester enameled copper wire with amide imide coating (FEAI)

Used for high-frequency coils, width coils, induction cooker coils, high-frequency power supplies, etc.

1. Stranded enameled copper wire (LITZ)

Temperature resistance and other poles: according to the selected enameled wire wire.

Insulation description: According to different applications, there are a variety of different insulation wire choices, and the advantages of each enameled material are retained.

characteristic:

(A) It can balance the magnetic flux chain and impedance, so that the current is evenly distributed on the conductor, which can reduce the high-frequency power loss caused by the skin effect.

(B) It has good impedance stability, and its AC and DC impedance ratio does not follow the wave.

Application range: high-frequency coils, width coils, induction cooker coils, high-frequency power supplies, etc.

2. Self-fusing enameled copper wire (R*-SB)

R* represents various types of synthetic insulating resins.

Temperature resistance grade: According to the selected bottom insulation wire, there are 130, 155, 180, 200, 220 degrees and other temperature resistance grades.

Insulation description: The composition of R*-SB depends on different applications. There are a variety of different insulating materials. The insulating layer can choose UEW, PEW, EIW, SEIW, EAIW, AlW, and the self-fusing layer has solvent to melt and heat. Melted.

characteristic:

(A) The coil can be shaped according to the fusion layer, and the impregnation and shaping procedure can be avoided.

(B) It has good winding characteristics and can withstand high-speed automatic winding operations.

Applications: Inductors, voice coils, etc.

3. Polyester enameled copper wire with amide imide coating (FEAI)

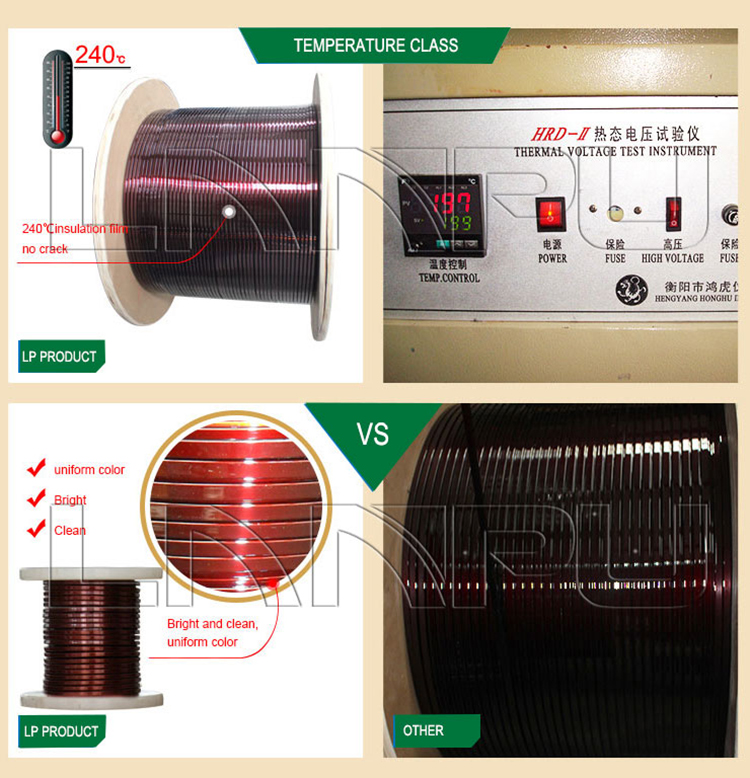

Extreme temperature resistance: 165 degrees

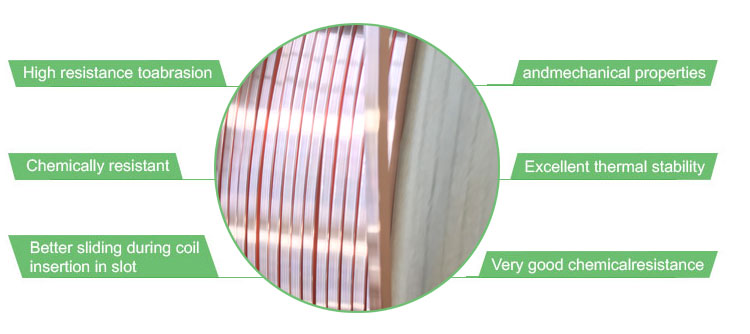

Insulation description: FEAI is double-layer insulation. This combination improves the wear resistance of PEW to obtain the best characteristics. Because the outer layer is self-sliding AI and has excellent winding linearity of nylon coating, it is better than PEW+NY The temperature resistance and mechanical properties of the wire type.

characteristic:

(A) The wire surface is smooth, the wire resistance is extremely low, it is easy to operate, and the coil volume is small and strong.

(B) The temperature resistance is 165 degrees and the wear resistance is excellent, the winding is not easy to break the skin, and the characteristics are far better than the general 155 degrees PEW.

(C) It has excellent winding linearity, suitable for high-speed winding or automatic winding.

Applications: Relays, sealed coils.