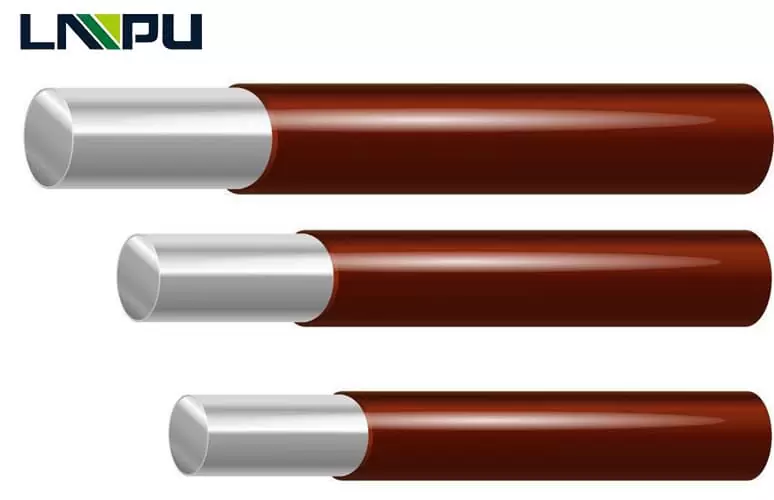

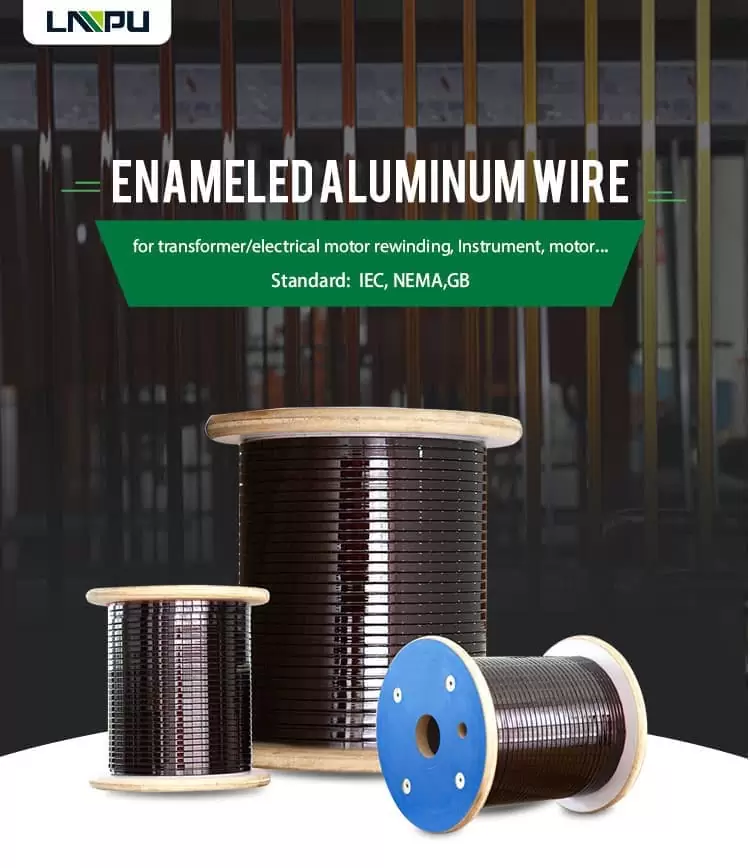

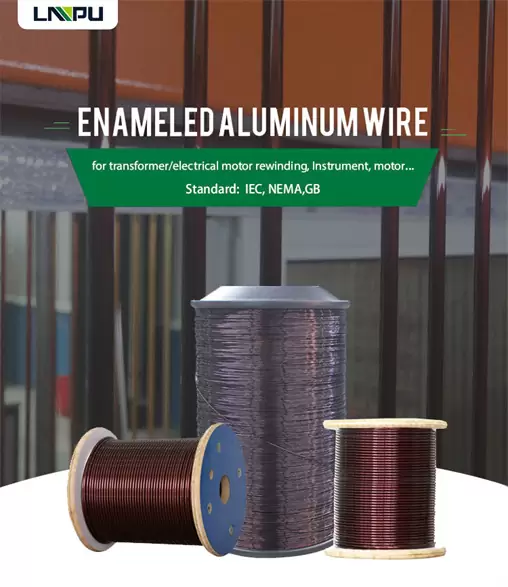

Solderable Self-Bonding 0.14Mm Enameled Aluminum Winding Wire

Product Name:Solderable Self-Bonding Winding Wire

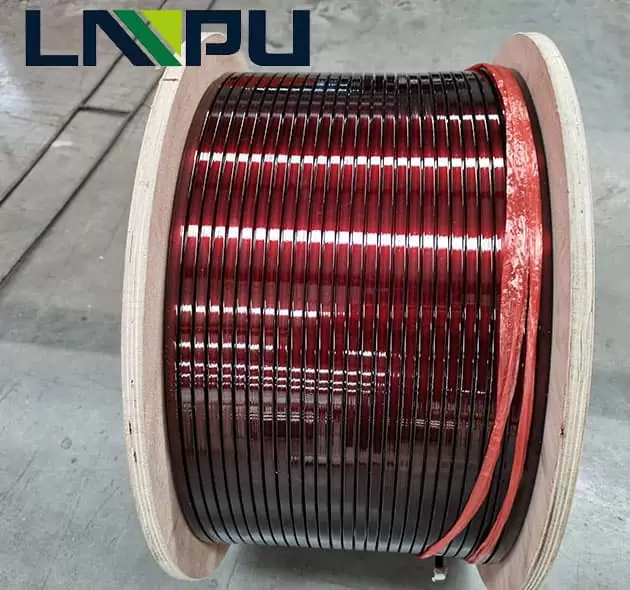

Type: flat or round wire

Round Dimension:0.14

Conductor Material:Aluminum

Application:used for transformers, inductors, motors, generators, dry type transformer, Cast Resin Transformers

Certificate:UL,RoHS

Insulation Materilas:UEW, QZ, QZY, EIW, etc.

Thermal Class:105¡æ, 120¡æ, 140¡æ, 155¡æ, 180¡æ, 200¡æ, 220¡æ, 240¡æ

As a special type of enameled wire, Solderable Self-Bonding 0.14Mm Enameled Aluminum Winding Wire, because of its special processing performance makes the manufacture of the coil simple and easy. The wound coil can be bonded and formed after heating or solvent treatment, so it is very popular, and it is widely used in the manufacture of various complex shapes or skeletonless electromagnetic coils. The application of self-adhesive enameled wire also brings significant social and economic benefits, which can simplify the coil forming process, improve work efficiency, save energy, and improve environmental pollution, which is conducive to industrial production.

The self-adhesive enameled wire almost all adopt a composite layer structure, that is, a self-adhesive paint (self-adhesive layer) is applied to the general enameled wire (baseline). At present, foreign countries attach great importance to composite enameled wire, which has many varieties and good performance. Since the composite enameled wire is made of two layers (or three layers) of lacquer coating of different materials, compared with a single-coated enameled wire of the same material, the composite wire has the respective properties of two different materials and overcomes the The lack of performance caused by the same material. In the composite layer self-adhesive enameled wire structure, the baseline is the main insulation part of the whole wire. In a certain sense (except for the composite effect), it guarantees the insulation performance of the self-adhesive enameled wire; the self-adhesive layer is mainly to meet the coil forming process. Need, it has a bonding effect and protects and enhances the baseline (the influence of the composite effect on the comprehensive performance of the enameled wire