Skills To Identify CCA Wire

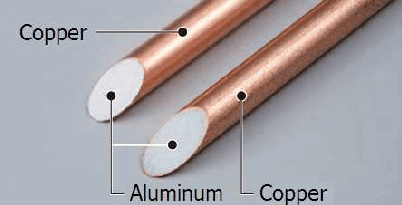

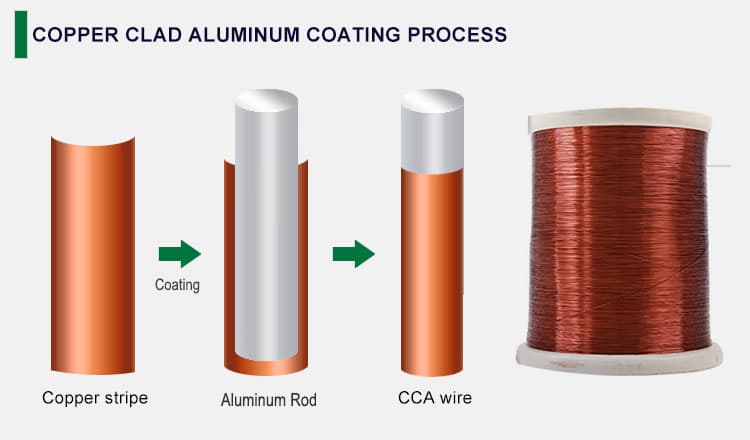

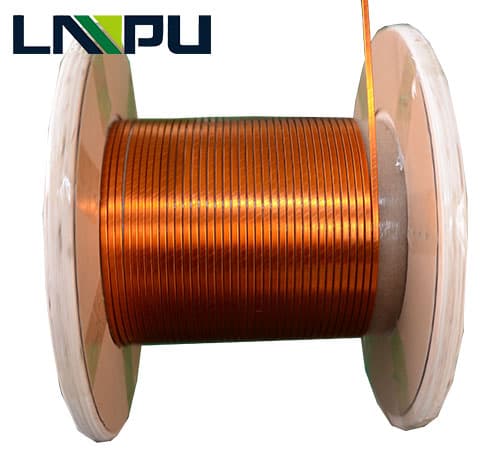

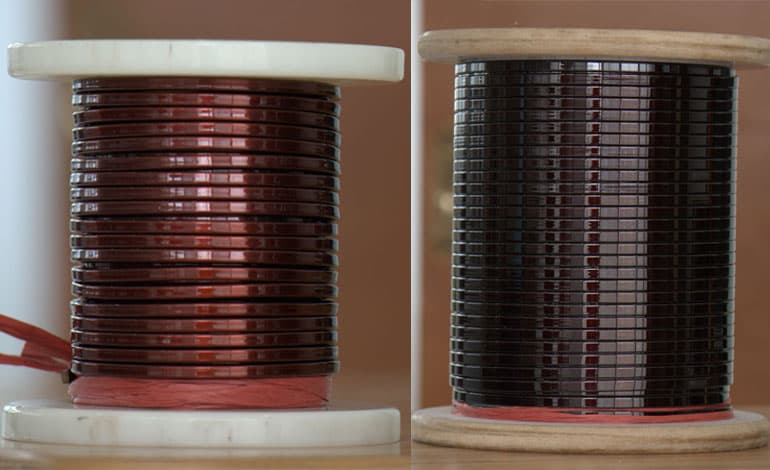

Copper-clad aluminum wire refers to a wire with aluminum core wire as the main body and a certain proportion of copper layer plated on the outside. It can be used as a conductor for coaxial cables and wire and cable conductors in electrical equipment. The aluminum wire has a small specific gravity, but its welding performance is not good. Therefore, the copper-clad aluminum wire is wrapped with a copper layer on the aluminum wire. This copper-clad aluminum wire can not only take advantage of the small aluminum specific gravity, but also improve the welding performance.

Therefore, you found some Category 6 cables on the Internet, and the price is almost half of what you pay for the brand. It claims to comply with TIA-568-C, includes the UL Listing Mark, and even has an ETL verification legend printed on the cable. Before you get too excited, you may need to make sure that the cable is not made of copper-clad aluminum (CCA).

It is cheaper than using solid copper wire, and cables made with CCA conductors are not worth the risk at all. Not only are they not compliant with the standards, they usually do not have a valid UL safety list under National Electric Not Worth the Savings or RiskCode (NEC).

What about the UL mark on the box? If the cable is manufactured with CCA and claims to comply with the standard, it may be a counterfeit cable, which means that the UL mark may not be authorized. UL listed cables have received the safety list because they have passed strict flame propagation tests to reduce the spread of fire. If the UL list is false, then security may also be false.

Heat balance method

Although the biggest concern surrounding counterfeit CCA cables should be security risks, these types of cables can significantly reduce network performance—especially as PoE is increasingly used for slave phones, laptops, and Wi-Fi access points. All devices to the video surveillance camera are powered, digital displays and even LED lights.

The resistance of aluminum cables is about 55% higher than that of copper cables of the same diameter. This means that more heat is generated in the CCA wire cable and the voltage available to the terminal equipment is lower. Therefore, not only the terminal equipment may not be able to obtain the required power, but the increase in heat in the cable bundle will also cause the insertion loss to increase, because the signal attenuates more in proportion to the temperature.

It’s not just heat that causes the problem. When transmitting power, it is separated between each conductor of a pair of conductors. If the resistances of the two conductors are equal, the unbalanced DC resistance (the difference in resistance between the two conductors) is zero, and the current is evenly divided to achieve a common mode current. However, this is rarely the case with CCA cables.

Although good process and termination consistency is important to prevent DC resistance imbalance, changes in diameter, concentricity (roundness), profile, and smoothness in CCA cables can lead to a higher risk of imbalance, which makes Ethernet The waveform of the data signal is distorted. The result is greater errors, retransmissions, and even invalid data links.

Versiv kit configurator

How will you use Versiv?

Stroll around

This is why you test it

There are some techniques for identifying CCA cables, including scratching the conductor to reveal the silver aluminum under the copper coating, and even weighing the box because aluminum is lighter than copper.

If the cable is already installed and the customer is not satisfied with the performance (especially if the CCA cable is not a problem), cutting the cable and scratching the conductor is not the preferred method. And there are reports that ballasts are placed in cable boxes or counterfeiters use heavier CCA versions to match the weight of real copper cables.

Then comes the test. Not only is it important for verifying standard compliance and application assurance, but it may also help to detect CCA cables. Analyzer can test DC resistance imbalance, verifying that the two conductors in a pair have the same resistance to enable common mode current and effectively support PoE, while avoiding distortion of the data signal transmitted on the same pair.

When testing the CCA cable, found that the DC resistance imbalance was clearly out of specification. The data showed that regardless of the link length, the CCA could not pass the DC resistance imbalance. In addition, as the number of devices running Gigabit Ethernet and PoE at the same time continues to increase, and the power provided through PoE increases, field testing of DC resistance imbalance becomes more important-for all cables. Click here to learn more about the importance of DC resistance imbalance in testing PoE applications.