Selection and application of copper wire drawing fluid for enameled wire

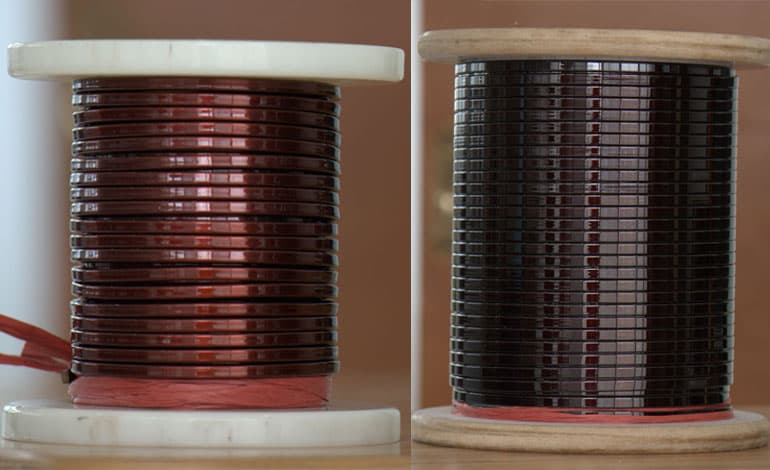

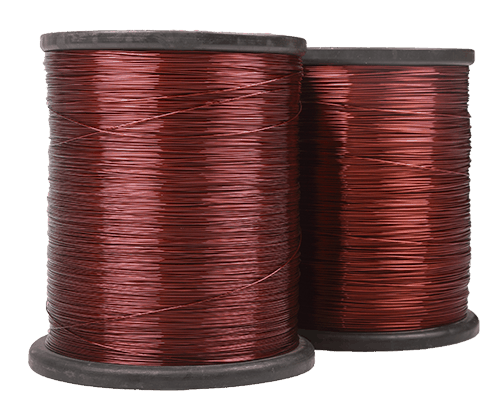

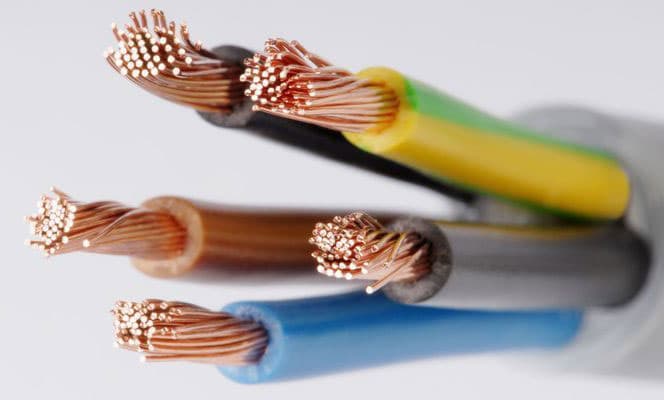

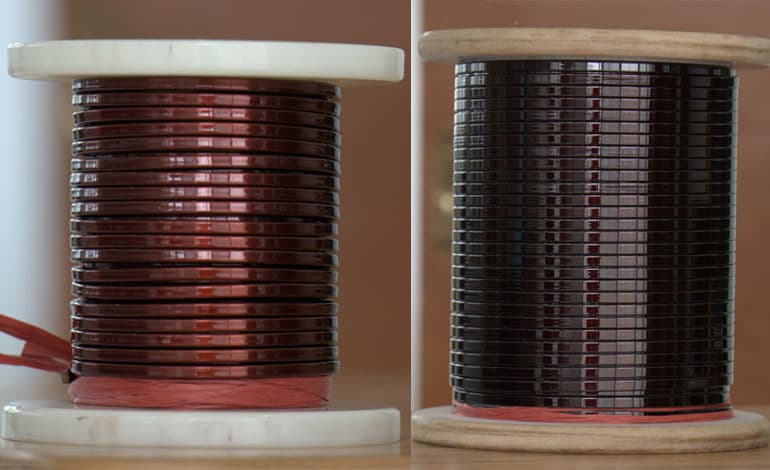

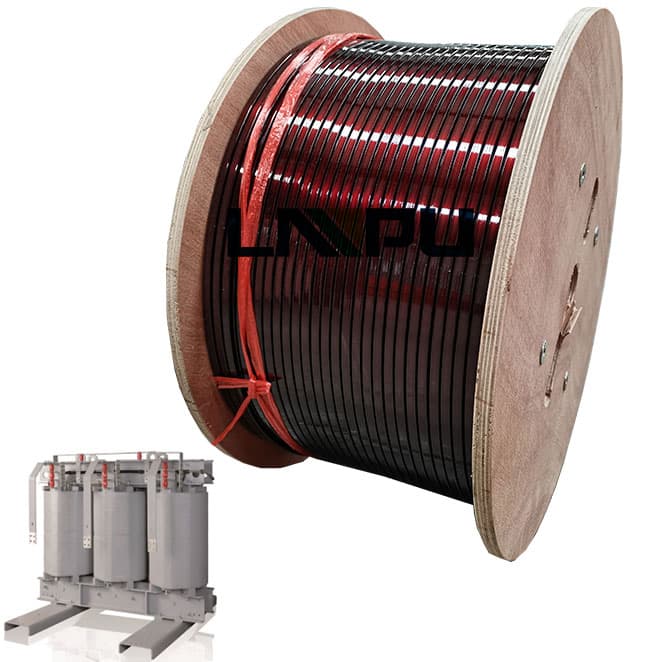

The wire drawing metal processing technology can form fine lines on the surface of the metal material, which makes the metal more textured, and is used as a decoration by users and is well-loved. In the production process, the drawing lubricating fluid is indispensable in the drawing metal processing technology. It is widely used in the lubrication of the middle drawing, small drawing and micro drawing of enameled copper wire. So how to choose this kind of drawing fluid?

First of all, we have to observe the sedimentation of the drawing liquid. A good enameled wire copper drawing liquid has a good sedimentation property, can keep the drawing system clean, and is easy to clean and remove pollutants, which is conducive to the secondary recycling of the drawing liquid. Secondly, the oil film of the good drawing fluid is thin, and ultrasonic cleaning is easier to clean, especially when making enameled copper wire. The poor drawing fluid is not only thicker, not easy to clean, and has poor sedimentation properties. Impurities are easy to accumulate, causing the enamel to fail to go up. Therefore, a good drawing fluid has a stable lubricating effect, and the oil film strength is relatively high, which can reduce friction and reduce power consumption.

At the same time, we should also pay attention to the use of enameled wire copper wire drawing fluid:

First, the concentration of enameled wire copper wire drawing liquid. Before use, pour one-third of the water in the wire drawing liquid into the oil tank. We need to adjust the appropriate concentration of the wire drawing liquid, which will help eliminate the adhesion of copper powder during the processing and keep the wire drawing liquid clean. Maintaining the stability of the drawing fluid not only makes the drawn copper wire beautiful, but also facilitates the recycling and reuse of the drawing fluid.

Second, the replacement of enameled wire copper wire drawing fluid. In use, the stability of the drawing fluid will not remain unchanged. With the evaporation of water and the precipitation of residual substances, the salt on the copper wire will change the composition of the drawing fluid, so we need to check the drawing fluid regularly. , Measure its conductivity, so as to determine whether to replace the drawing fluid.

Choosing a good copper wire drawing fluid for enameled wire can improve the work efficiency in the metal wire drawing process, and can also improve the quality of processing. Due to quality problems, bad copper wire drawing fluid for enameled wire will not only delay the work efficiency of the drawing process, but also affect the quality of processing. , Affecting customer service satisfaction, and more importantly, using bad wire drawing fluid will damage the machine, causing machine failure and shortening the service life of the machine. So when choosing enameled wire drawing fluid, don’t just consider the price factor, we should choose the one with good quality that suits us.