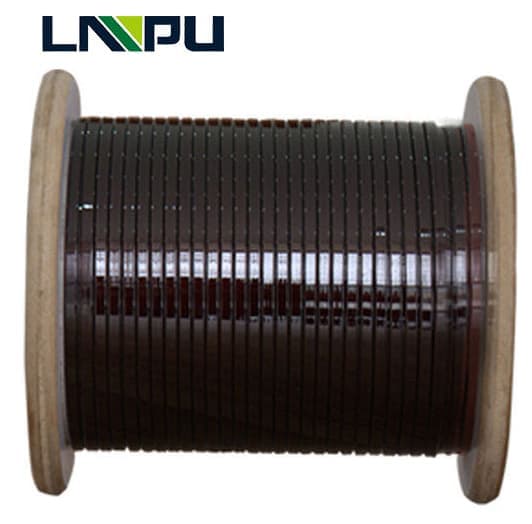

Rectangular Aluminum Magnet Wire

Rectangular Aluminum Magnet Wire

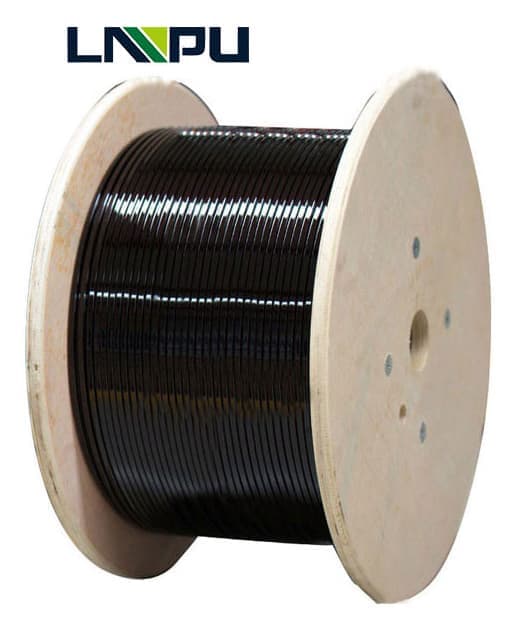

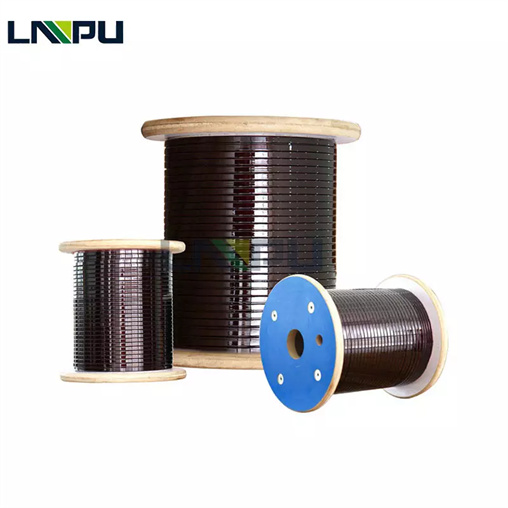

Rectangular: A> 0.8–8mm, B> 2-22.5mm

Wire Enamel: UEW(QA), PEW(QZ), EIW(QZXY), EI/AIW(QZY) ;

thermal class: 180(Class H), 200(Class C), 220(Class C+), 240(Class HC)

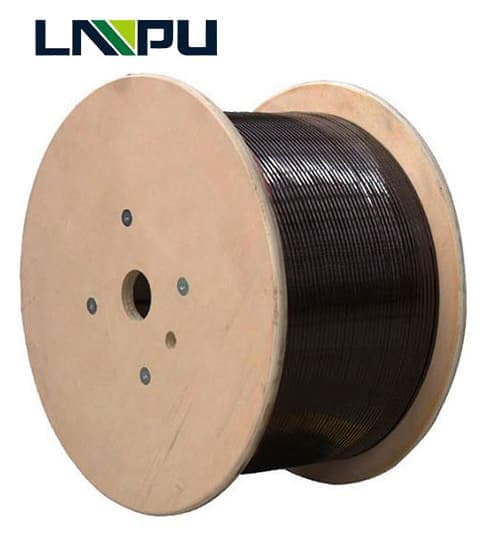

Enamelled Rectangular aluminum Magnet wire are used as the wire in electromagnets that use electricity to generate a magnetic field. Rectangular or Flat Aluminium Wire and Rectangular or Flat Copper Wire /Strip is wrapped in a tight coil. When an electric charge is applied, the wires generate the magnetic field.

Flat Enamelled Aluminium Wire and Flat Enamelled copper wire have a wide variety of applications, including use in automobiles, motors, transformers and industrial machineries.

Round Enameled Aluminium Wire and Round Enameled copper wire are also found in smaller devices and home appliances, such as computers, televisions etc.

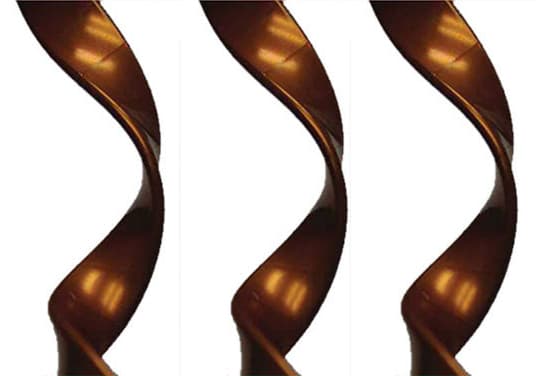

Breakdown voltage of Aluminium Enamelled Winding Wire or Copper Enamelled Winding Wire depends on the thickness of the covering, which can be of 3 types: Grade 1, Grade 2 and Grade 3. Higher grades have thicker insulation and thus higher breakdown voltages.

Other types of insulated conductors such as fiber glass insulated copper / aluminium round & flat wires with varnish, nomex insulated copper / aluminium round & flat wires, kraft paper insulated copper / aluminium round & flat wires, mica insulated copper / aluminium round & flat wires, kapton insulated copper / aluminium round & flat wires, and polyester film insulated copper / aluminium round & flat wires are also widely used across the world for various applications like motors, transformers and reactors.

IEC 60317-13:2010 specifies the requirements of enamelled round copper winding wire of class 200 with a dual coating. The underlying coating is based on polyester or polyesterimide resin, which may be modified providing it retains the chemical identity of the original resin and meets all specified wire requirements. The superimposed coating is based on polyamide-imide resin. The main changes with respect to the previous edition are:

– new requirements for appearance;

– reference to new resistance to refrigerants test in IEC 60851-4