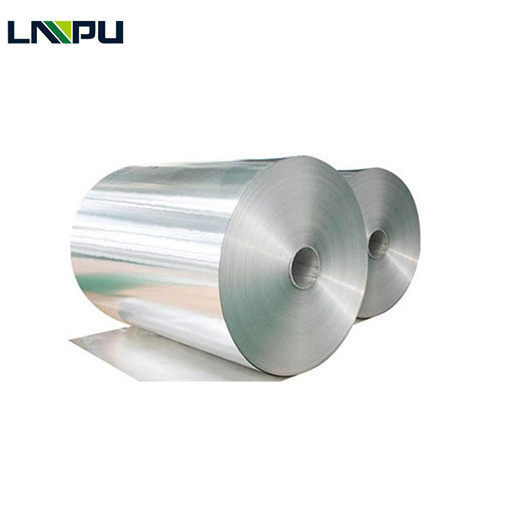

Pure aluminum foils For electrical purposes

According to the aluminum content, the aluminum foil can be divided into pure aluminum foil and aluminum alloy foil. The pure aluminum foil includes 1050,1060,1100 and 1235. What are their properties and uses? Lets have a look together. Take 1050 and 1060 for making comparison.

1050 Aluminum foil

1050 aluminum foil contains 99.5% aluminum, which is of high plasticity, strong corrosion resistance, excellent electrical and thermal conductivity, etc. It is widely used in gaskets, electronic capacitors, food packaging, lunch box materials, and electronic labels,etc.

Its aluminum foil appearance is of clean oil removal, less pinholes, good product shape, and no deformation during cutting. And it has good corrosion resistance and no low brittleness, which is a good choice for the material of low-temperature container.

1060 Aluminum foil

1060 aluminum foil contains 99.6% aluminum, 1060 aluminum foil is of high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. It is an ideal choice for making electronic labels for it has good forming performance and cutting processing performance and good reflection performance on radio waves that speeds up the scanning.

It is also an main bottle cap material. 1060 aluminum foil is used to make caps in a way of aluminum-plastic combination. Because the aluminum-plastic combined part will contact the liquid in the bottle, most of 1060 aluminum foils are applied to the cosmetics industry and pharmaceutical industry.

At same time, the 1060 foils are widely used in cast resin transformer winding.

Welcome to see the aluminum foil in Lanpu.