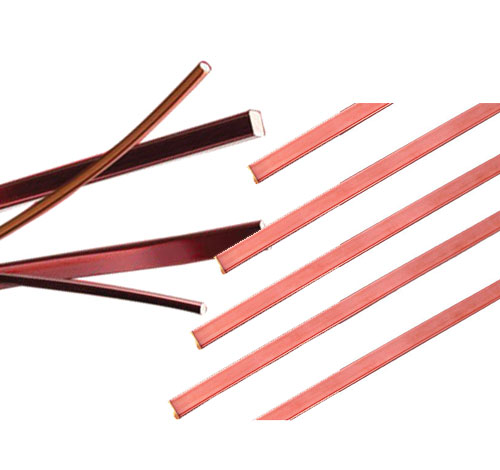

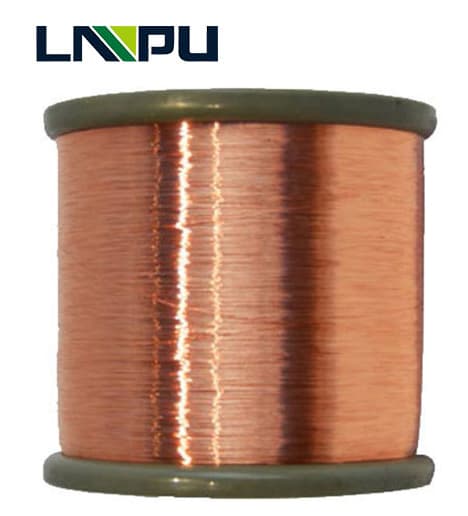

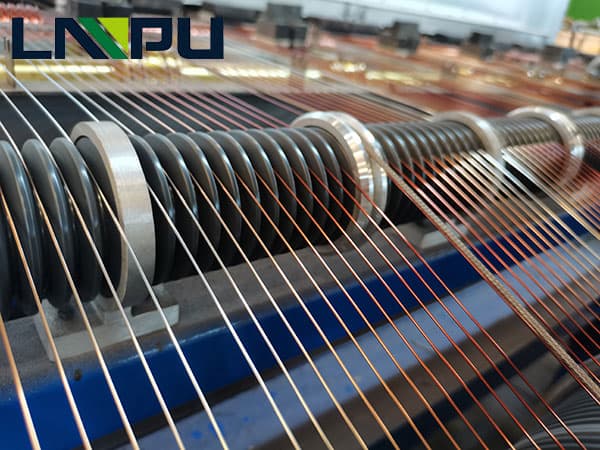

Poor soldering tin of enameled wire

Poor soldering is mainly manifested in that the paint film after soldering will not melt off after the soldering, which causes the phenomenon of poor soldering.

Question:

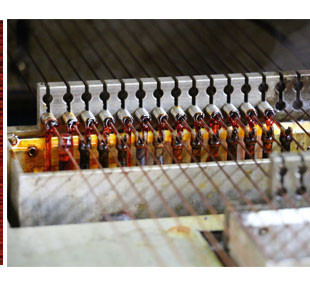

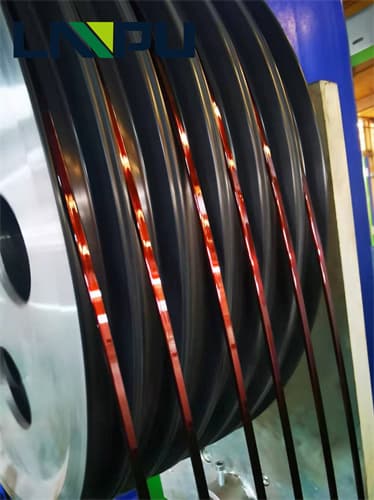

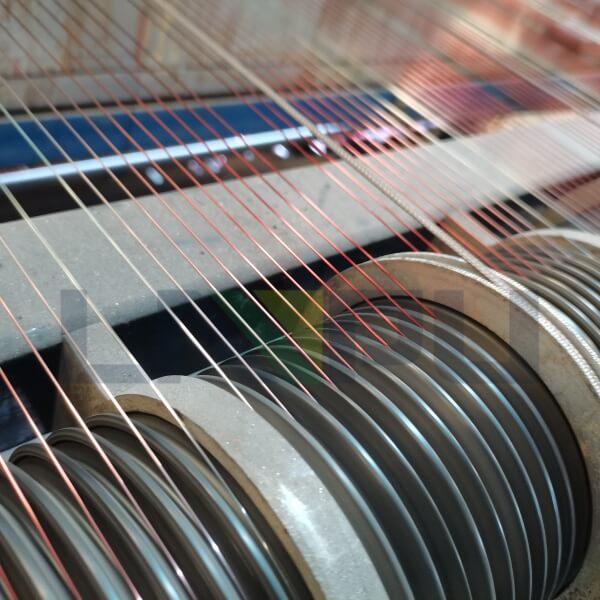

Manually adding flux to repair soldering, the effect is not ideal; the liquid level of the solder in the picture above is sufficient, and the amount of flux is also a little more than usual. This product has 6 pins to be welded, only the wire of this winding cannot be welded. At the same time, the product produced on the same day cannot be welded on this wire. Semi-automatic soldering furnace, temperature 440¡æ, soldering tin 1.3S; enameled wire paint film is UEW (polyurethane).

Answer1

1. Look at the color, it should be a QA straight wire, but the soldering effect is poor. It is inferred that the raw materials of the enameled wire of this enameled wire are different from the conventional ones, and it may be an unconventional wire.

2. If only the winding is completed and the feet are not hung, the paint remover can be used to remove the paint and then the feet can be tinned. The source is still on the enameled wire itself, let the manufacturer send a copy of data to compare and see if it is any special

Answer2

What is the solder temperature? Is there a test? Is the solder temperature enough? The lower solder temperature can be appropriately increased, and the solder surface is free of dirt and residue. Generally, such a problem with straight soldering wire may be caused by the supplier’s enameled wire temperature resistance paint problem, such as 180 enameled wire and 130 enameled wire solder. difference. You can find the enameled wire manufacturer to analyze and find the reasons for improvement as soon as possible. There is basically no way to solve the products that have been made. Increase the solder temperature and try to see if it works.

Answer3

From the picture, the wire diameter is relatively thick. After tinning, the black one is enameled film. The paint film should be thicker. The tinning time should be increased to 2s. The flux should not be too much. If there is too much tinning, there will be black of. It is best to move down when tinning.