Polyimide Film Covered Aluminum Wire Production

Polyimide Film Covered Aluminum Wire Production Process

One step :

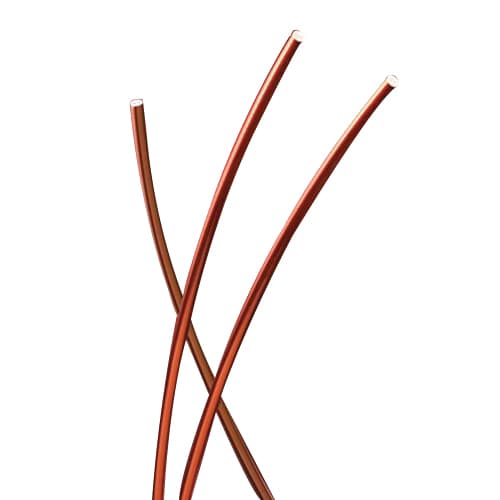

Take the pure aluminum material drawing into the aluminium rod wire;

Two step :

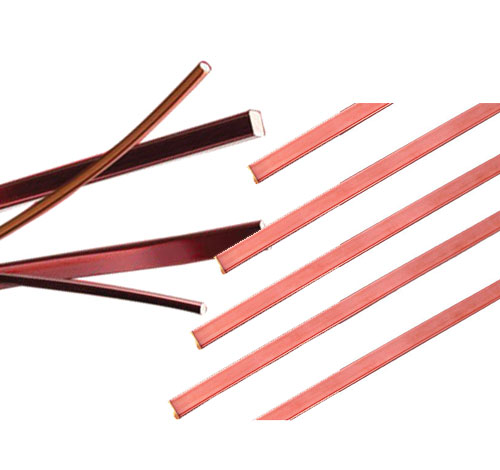

Through the extrusion production line, take the aluminum rod wire into extruding and coarse drawing operation, then becoming the requirement specification of Bare aluminium wire;

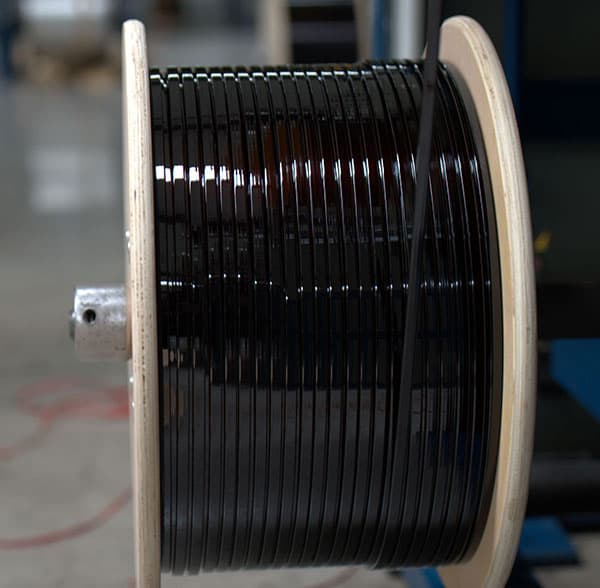

Three step :

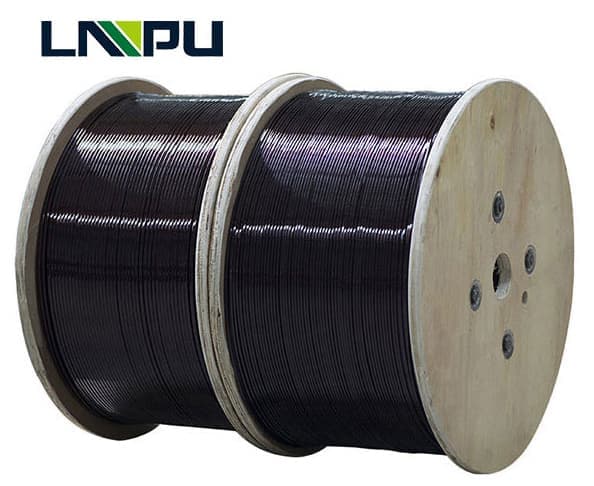

Take up the Bare aluminum wire conductor, and inspection the bare wire coil products;

Four step :

After annealing the alumium wire coil , cleaning and pay-off the wire coil, ready to next operation;

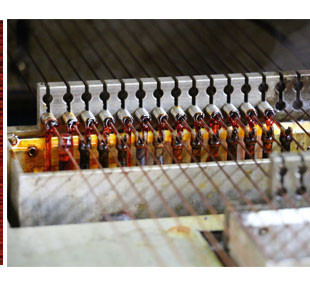

Five step :

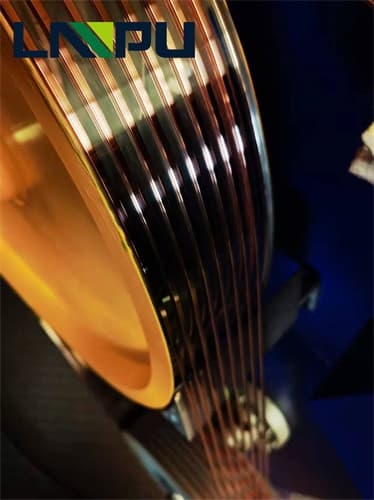

Taking into straightening and Tension levelling operation, varnish treat the surface of wire, and then for the glass fiber covered;

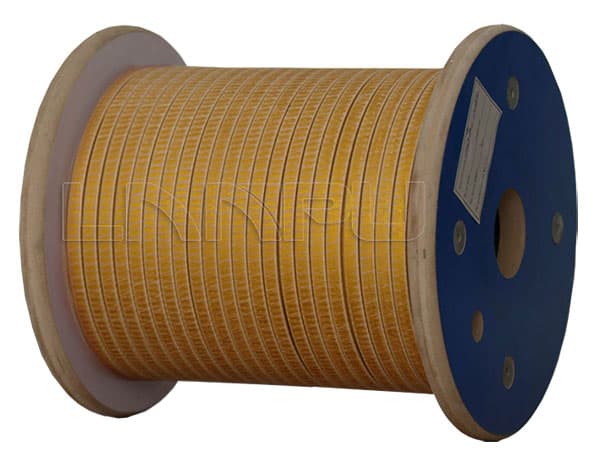

Six step :

And then for baking the fiberglass wire , pulling the finished wire, and take-up the fiberglass wire products.

Polyimide film aluminum wire is a multi-layer polyimide & fluoropolymer dispersion-coated film. The fluoropolymer coating functions as a heat-fusible layer for bonding to magnet wire conductors.