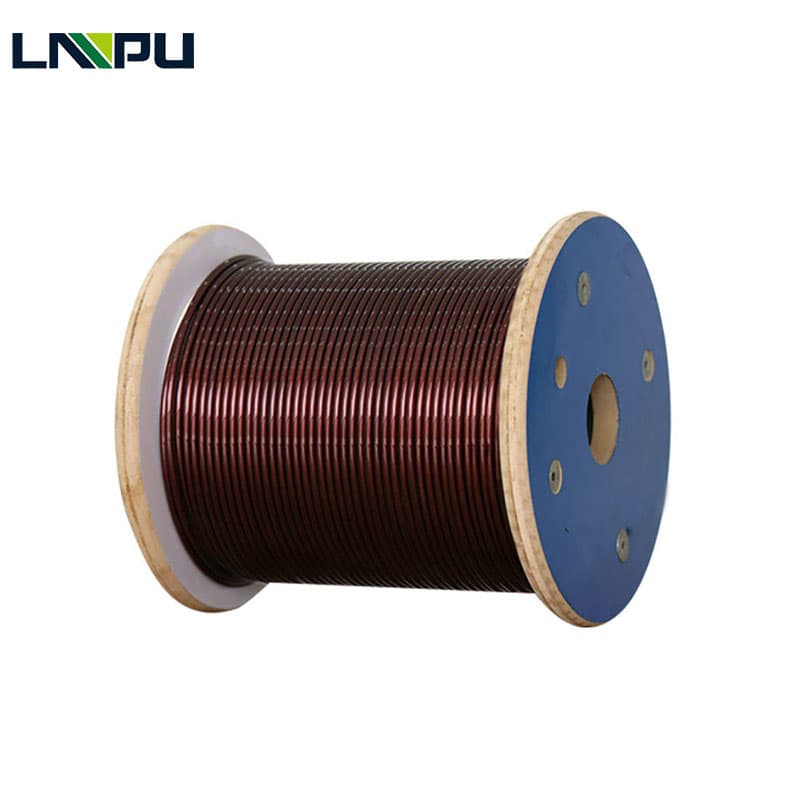

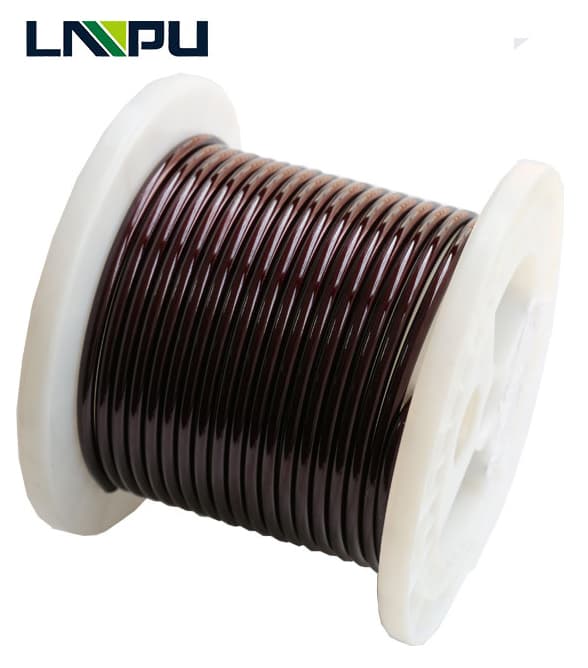

Polyester Enameled Aluminum Winding Wire

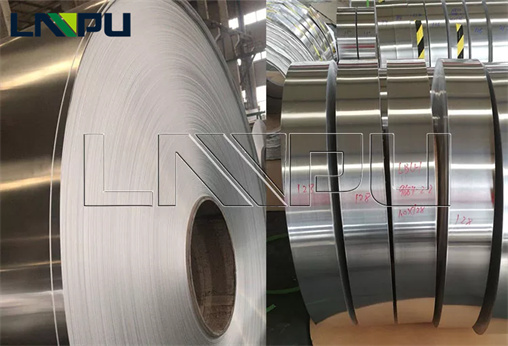

Composition of Polyester Enameled Aluminum Winding Wire

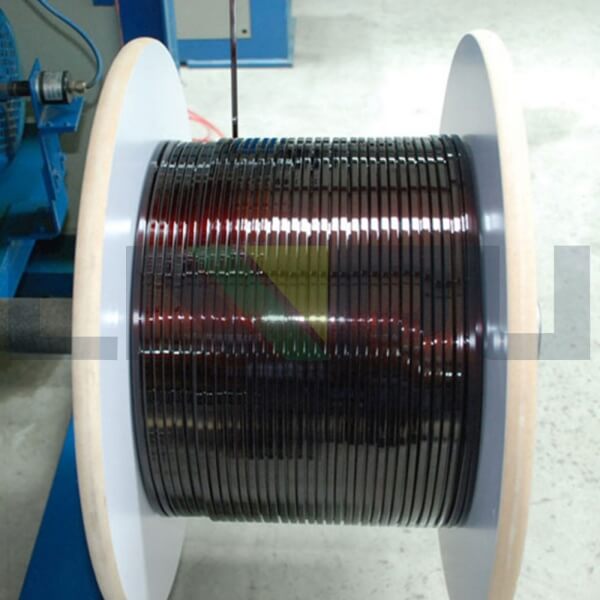

Polyester Aluminum Magnet Wire consists of a conductor and an insulating layer. After the bare wire is softened by annealing, it is painted and baked many times. It is not easy to produce products that not only meet the requirements of the standards, but also meet the requirements of customers. It is affected by many factors such as the quality of raw materials, process parameters, production equipment, and the environment. Therefore, the quality characteristics of various enameled wires are different, but they all have the same four major properties as mechanical properties, chemical properties, electrical properties, and thermal properties.

Introduction of Polyester Aluminum Magnet Wire

Polyester Enameled Aluminum Winding Wire, various enameled wires have different quality characteristics, but they all have the same four major properties: mechanical properties, chemical properties, electrical properties, and thermal properties.

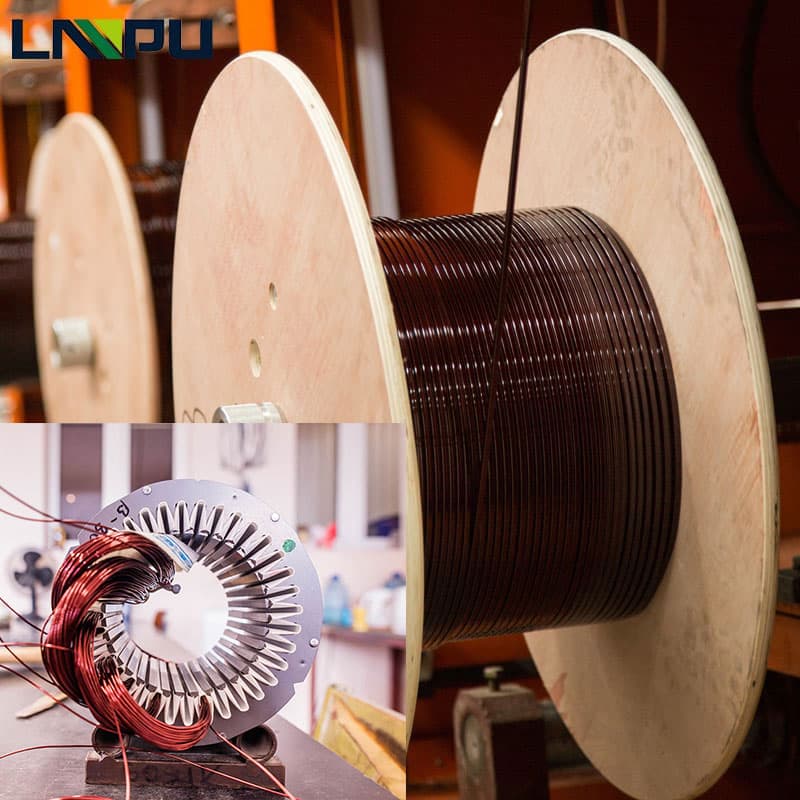

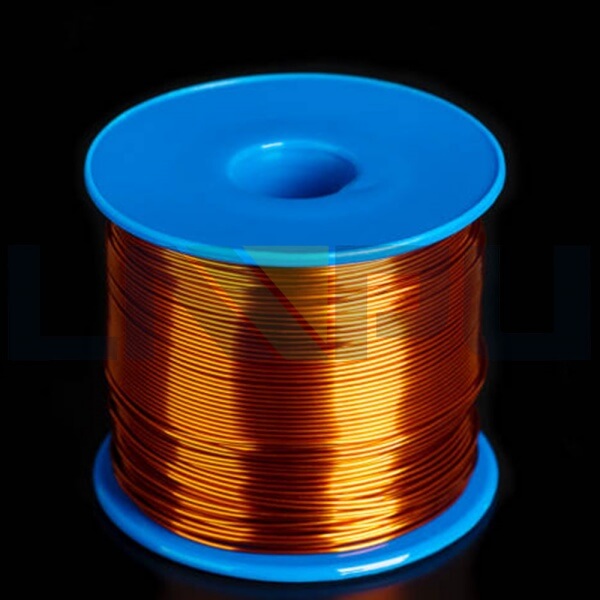

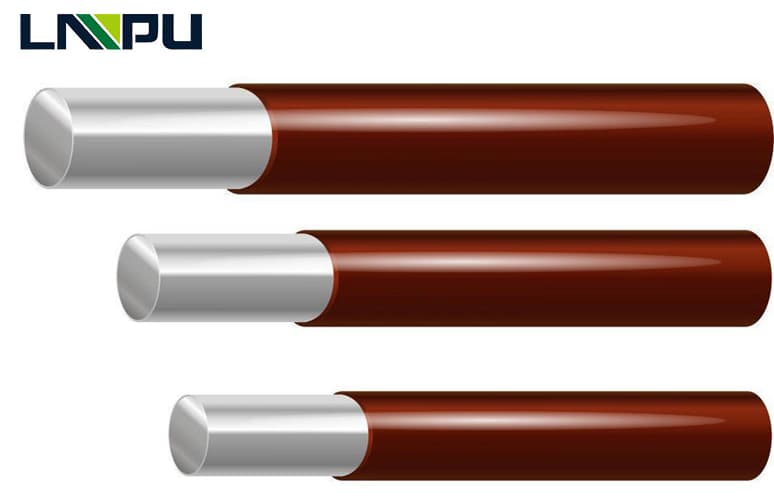

Characteristics and uses of Polyester Enameled Aluminum Winding Wire

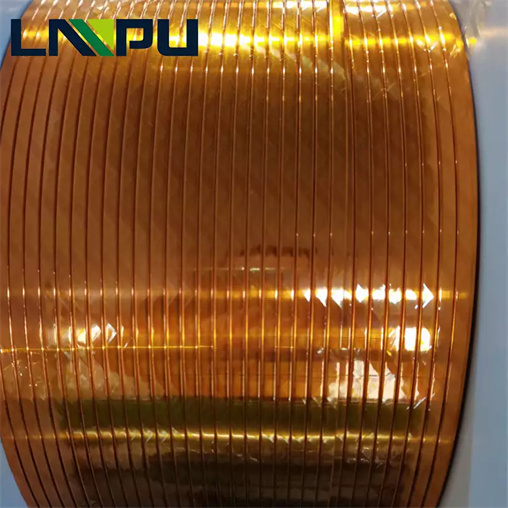

Polyester Aluminum Magnet Wire; thermal grade is 130 and 155. The biggest feature is that it has direct solderability, good high frequency resistance, easy coloring, and good moisture resistance.

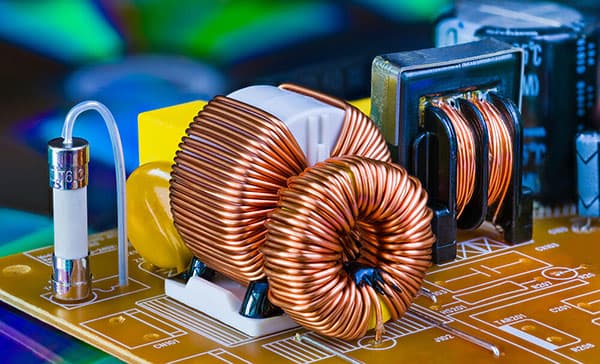

Polyester Aluminum Magnet Wire is widely used in electronic appliances, precision instruments, telecommunications, and meters. Product specifications range from 0.05 to 1.8.