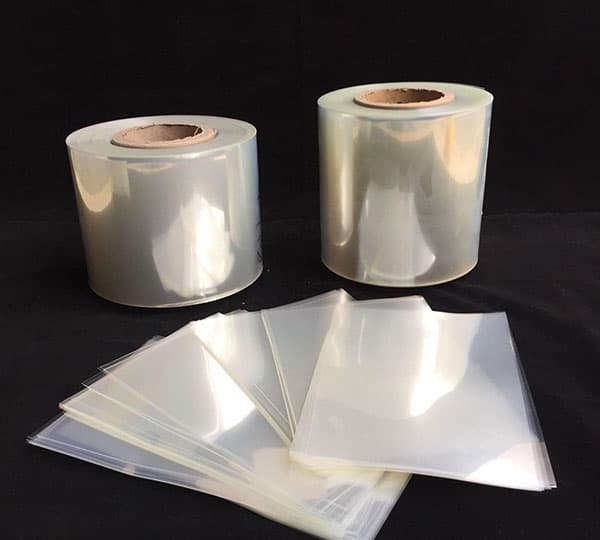

PET film

PET film is a more comprehensive packaging film. It has good transparency and luster; it has good air tightness and fragrance retention; it has medium moisture resistance, and its moisture permeability decreases at low temperatures. PET film has excellent mechanical properties, and its toughness is the best among all thermoplastics. Its tensile strength and impact strength are much higher than ordinary films; it has good stiffness and stable dimensions, and is suitable for secondary processing such as printing and paper bags. . PET film also has excellent heat resistance, cold resistance and good chemical resistance and oil resistance. However, it is not resistant to strong alkalis; it is easy to be charged with static electricity, and there is no proper anti-static method. Therefore, attention should be paid when packing powdery articles.

In addition to the excellent physical and mechanical properties of ordinary polyester film, the film also has excellent optical properties, such as good transparency, low haze, and high gloss. It is mainly used for high-end vacuum aluminized products. The film is mirror-finished after aluminizing, which has a good packaging and decoration effect; it can also be used for laser anti-counterfeiting base film, etc.

Transfer film is also called thermal transfer film. The characteristics of this transfer film are high tensile strength, good thermal stability, low thermal shrinkage, smooth and clean surface, good peelability, and can be used repeatedly. It is mainly used as a carrier for vacuum aluminization, that is, after the PET film is placed in a vacuum aluminizing machine for aluminum plating, glue is applied to compound with the paper, and then the PET film is peeled off, and the aluminum molecular layer is transferred to the surface of the cardboard through adhesion. The so-called aluminized cardboard is formed.