Home » magnet wire » Performance and use of enameled wire

Performance and use of enameled wire

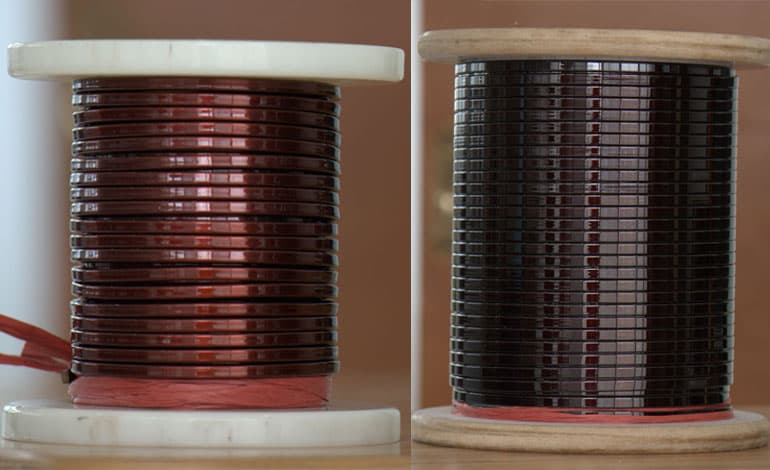

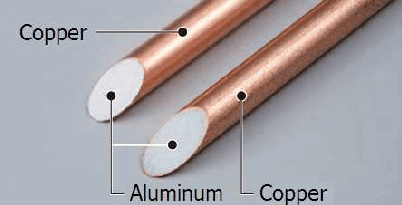

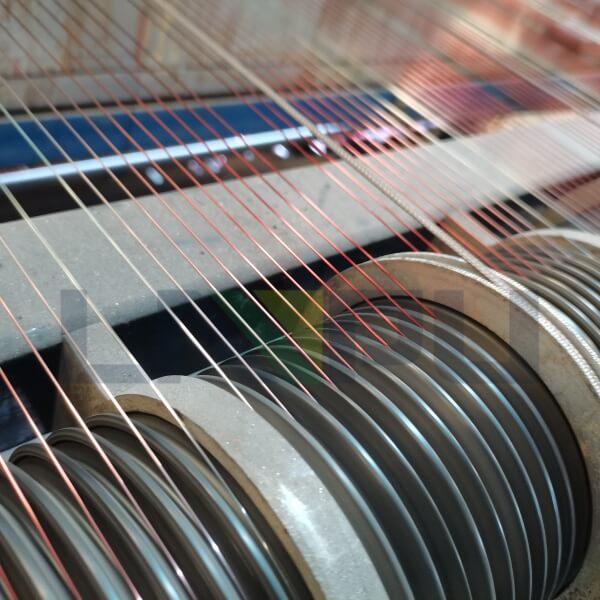

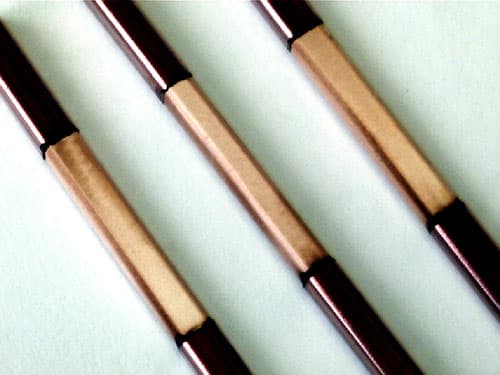

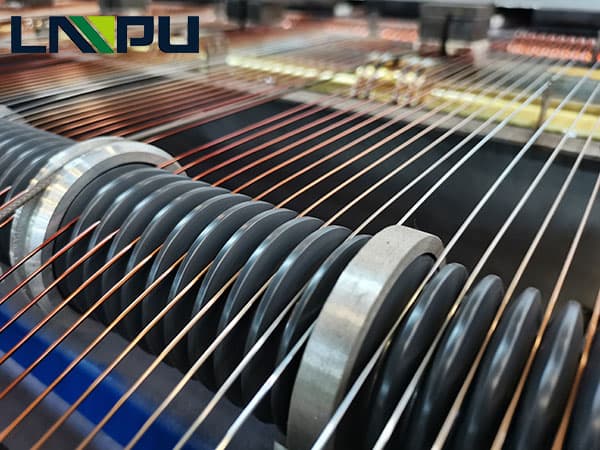

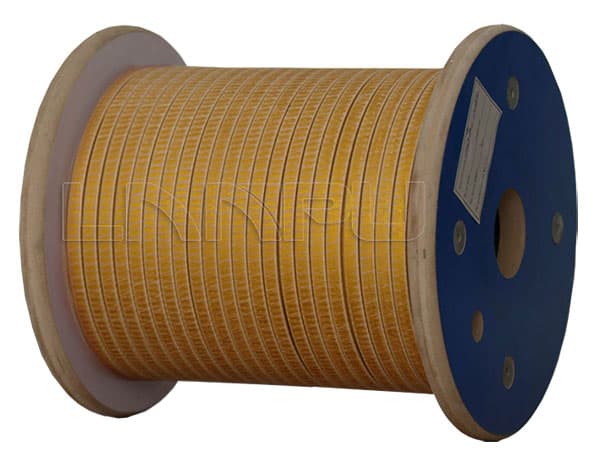

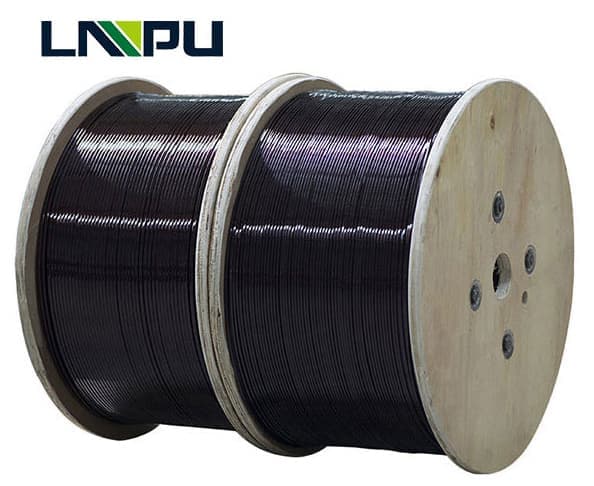

Enameled wires are widely used in industrial production, household appliances and other industries. The main properties and uses of various enameled wires are as follows: Various machines, communication equipment, meters, relays, small transformers, etc.

Contact US

Get Price

Share:

Content

| Types of Enameled wire | Characteristics | Main Application |

| UEW | Solderability | Various machines, communication equipment, meters, relays, small transformers, etc. |

| UEWE | Solderability,Good winding linearity | Small motors, deflection coils, etc. |

| PVF | Water resistant variable pressure oil, excellent heat and humidity resistance | Hydraulic transformer, underwater motor, enclosed motor, etc. |

| PEW | motor, transformer, etc. | |

| PEWN | Good winding linearity¡¢Excellent resistance to water | motor, transformer, etc. |

| EIW | Excellent heat and humidity resistance | Excellent heat resistance H motors, high-voltage transformers, etc. |

| EIWH | Good winding linearity¡¢Excellent heat resistance¡¢Excellent heat and humidity resistance | Special motors, high-voltage transformers, power tools, etc. |

| AIW | Excellent heat resistance, Excellent chemical resistance | Special motors, aircraft accessories, power tools, etc. |

| FBWHC | Self-adhesive | Deflection coil, high voltage transformer, etc. |

Inquiry

More magnet wire