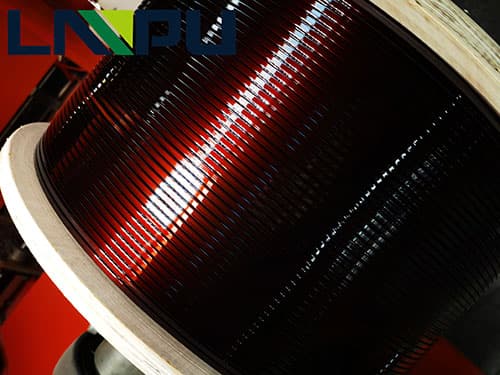

Online inspection of paint film continuity

Paint film continuity testing has used some offline testing methods, such as voltage mercury method, Japanese salt water method, low-pressure electrolyte method, etc., which are not suitable for online testing of enameled wire in the production process.

At present, the online detection system for the continuity of the enameled wire paint film used in most magnet wire manufacturers is a non-contact detection method based on a DC high-voltage electric field sensor. The basic principle is to generate a DC high voltage through a DC high voltage circuit and connect it to a cylindrical metal conductor in the high voltage electric field sensor, so that a high voltage electric field is generated inside the cylindrical metal conductor. Driven by the take-up wheel, The enameled wire passes through the high-voltage electric field at high speed. When the electric field is strong enough, a corona will be generated on the surface of the enameled wire. If the enameled wire with defective paint film passes through it, it will cause local formation between the metal conductor-enameled wire-take-up wheel Leakage current caused by discharge. By dynamically measuring the change of the leakage current of the enameled wire, the defect location and severity of the enameled wire can be accurately measured and recorded.

When this method is used for detection, during the whole process, the enameled wire and the sensor part are non-contact, so there will be no additional damage to the enameled wire, and it is very suitable for online detection of enameled wire running at high speed on the production line. Moreover, the metal conductor in the high-voltage electric field sensor is approximately cylindrical, and the electric field generated is basically the same in all directions, so the detection ability in all directions is basically the same, the detection sensitivity is high, and the situation of missed detection and false detection is not easy to occur.

Of course, the users of magnet wire can only use offline inspection, that is, the paint film continuity tester. Compared with the online inspection tester, because it is only a half-enveloped test, the ability to find defects is slightly weaker. However, in view of the randomness of sampling, it is basically possible to qualitatively determine the compliance of the electromagnetic wire’s performance.