Home » enameled aluminum wire » Non-woven Fabrics Wrapped Aluminum magnet wire Strips

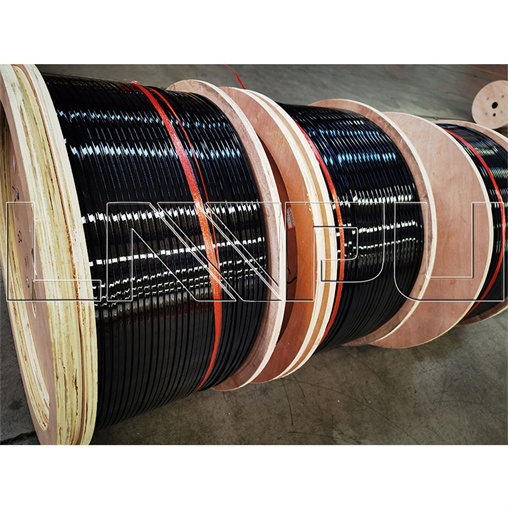

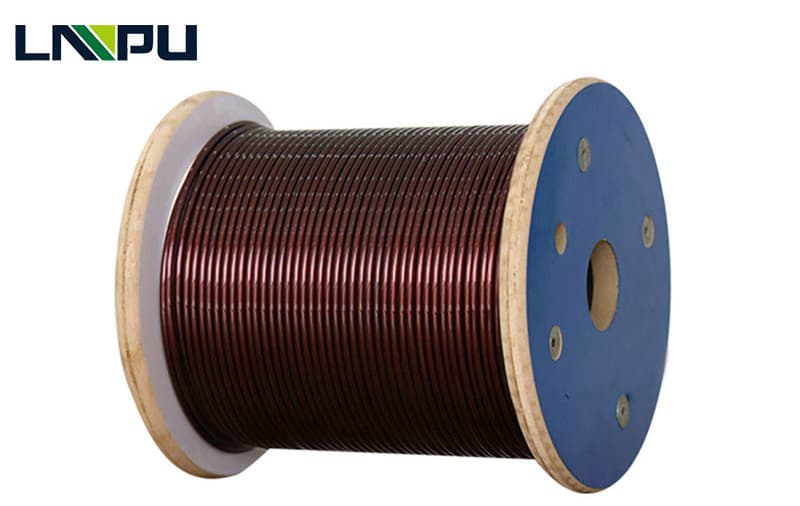

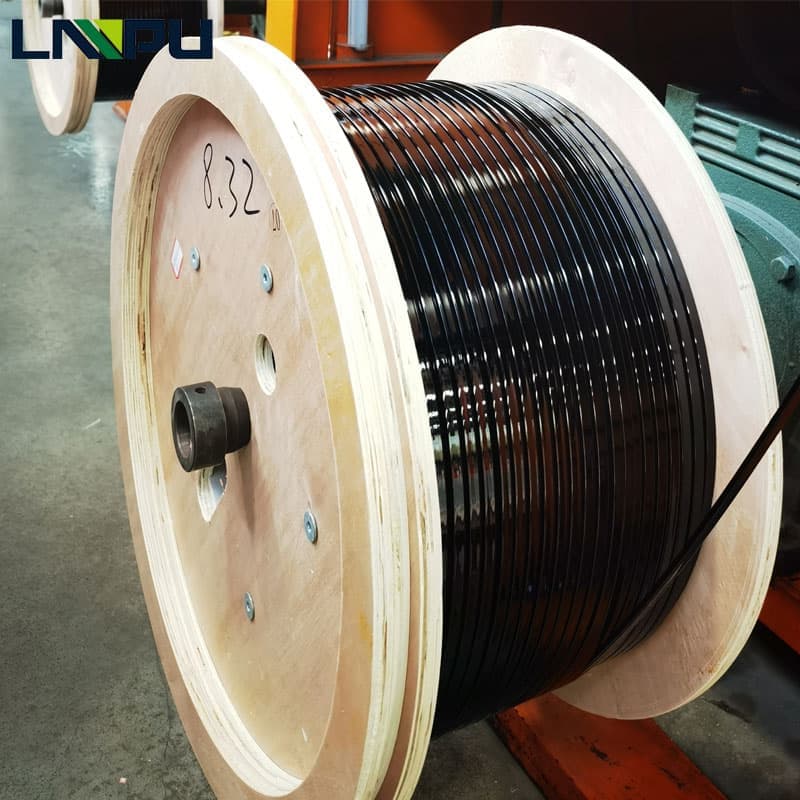

Non-woven Fabrics Wrapped Aluminum magnet wire Strips

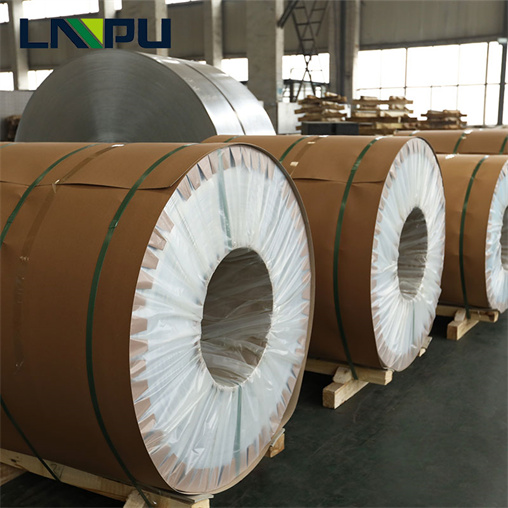

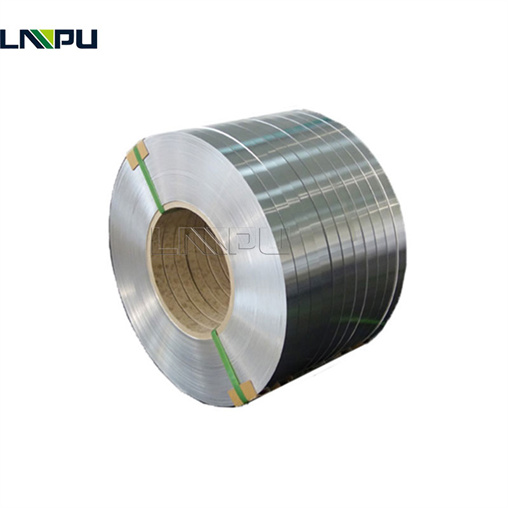

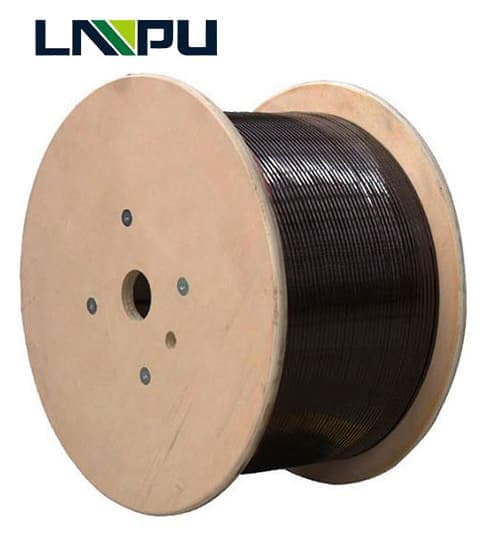

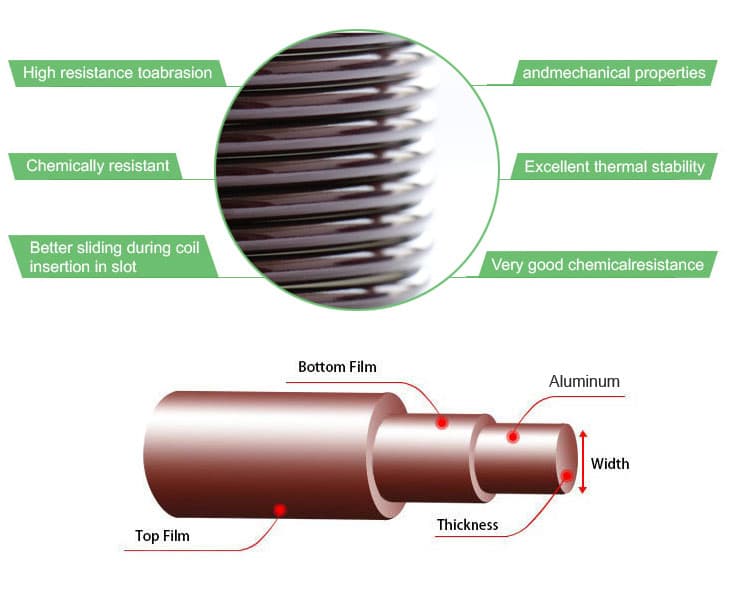

Non-woven Fabrics Wrapped Aluminum magnet wire Strips is made of oxygen free Aluminum rod or electrical round aluminum rod through a certain specification of the die extrusion or drawing after annealing treatment of the wire, and then on the Aluminum / Aluminum magnet wire strips on the 2-3 layer of polyester film or Non-woven Fabrics electrical insulation layer of the winding wire, the product is good, temperature resistance and other grade 130for B grade, mainly used for air core reactor.

Contact US

Get Price

Share:

Content

Conduct Materials:

Aluminum magnet wire strips should follow the standard of GB5584.3-2009, at 20¡æ the conductivity resistivity is not more than 0.028mm2/m.

Product breakdown voltage should follow below table:

| Wrapping type | Insulation Thickness(mm) | Breakdown voltage above | |

| Standard Value | Tolerance | ||

| 2 layers of polyester films | 0.22 | ¡À0.03 | 5000 |

| 2 layers of polyester films+1 layer of non-woven fabrics | 0.33 | ¡À0.03 | 5000 |

| 3 layers of polyester films | 0.30 | ¡À0.03 | 7500 |

| 3 layers of polyesters film+ non-woven fabrics | 0.42 | ¡À0.03 | 7500 |

Inquiry

More enameled aluminum wire