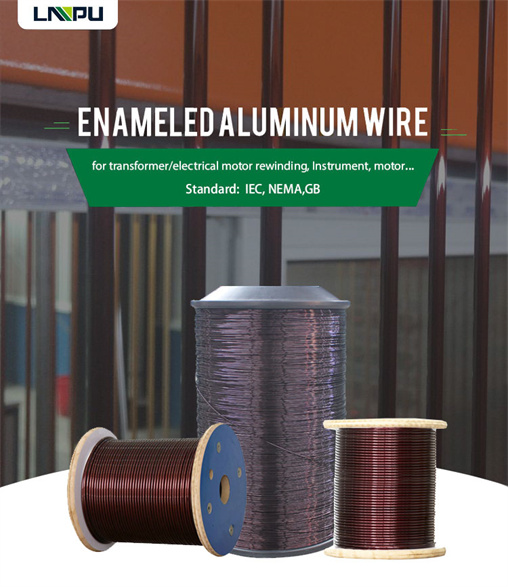

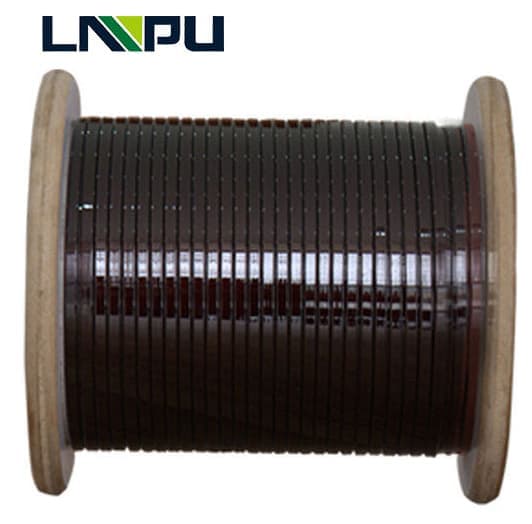

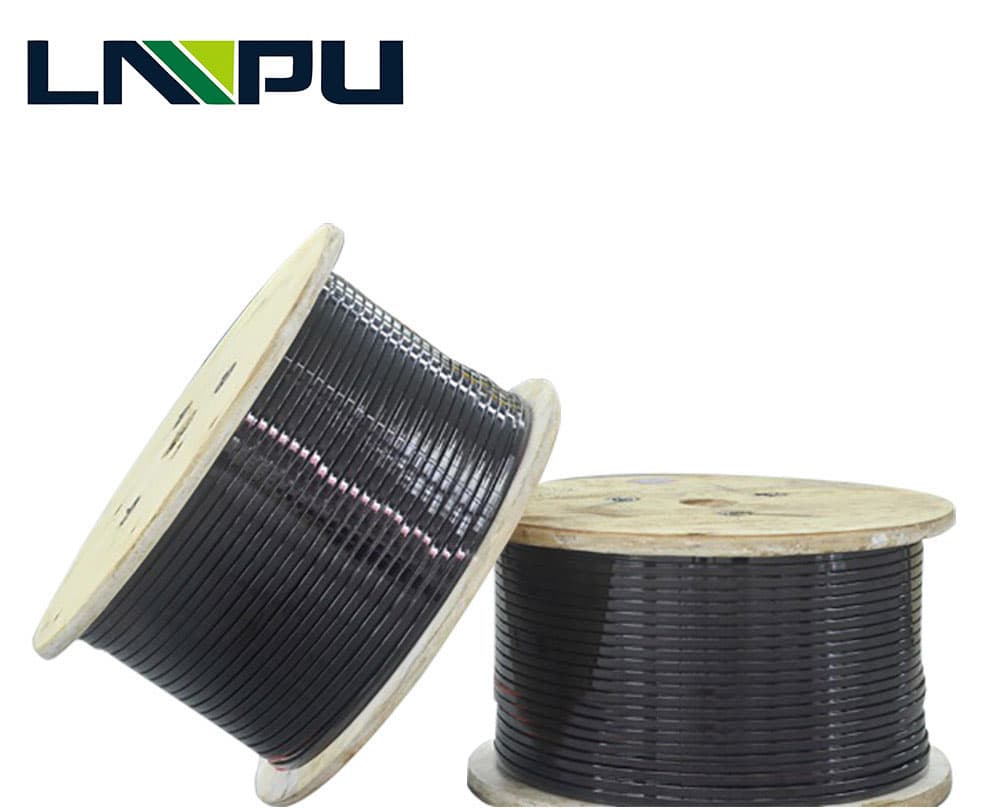

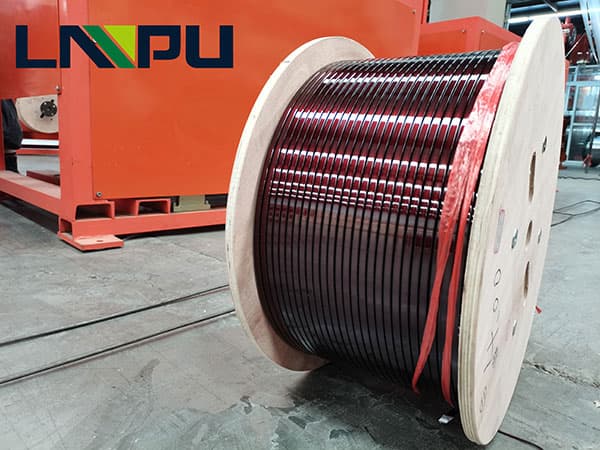

Motor Winding Material Electrical Aluminum Wires Manufacturer

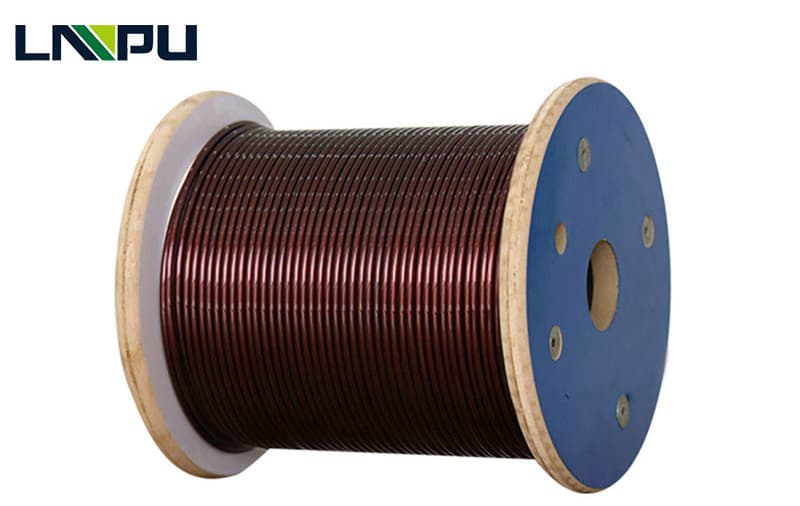

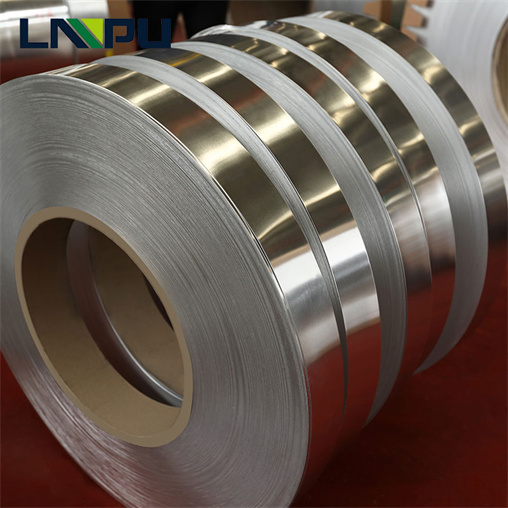

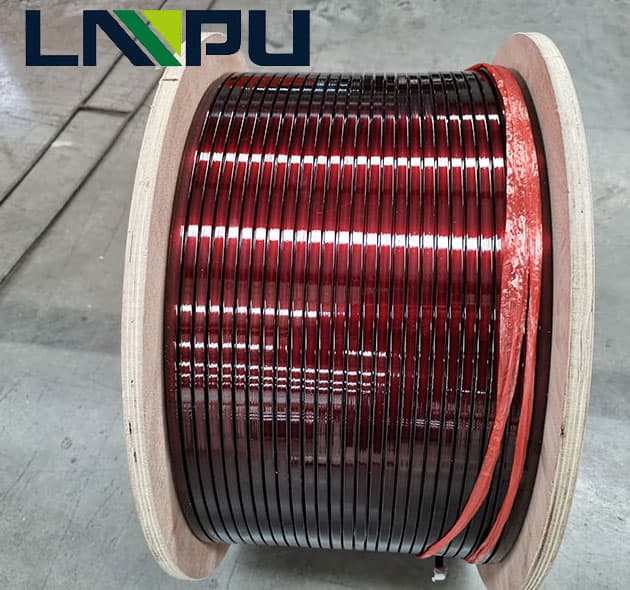

ZhengZhou LP Industry CO.,Ltd is a professional Motor Winding Material Electrical Aluminum Wires Manufacturer, Mainly provide Aluminum /Copper Wire/foils

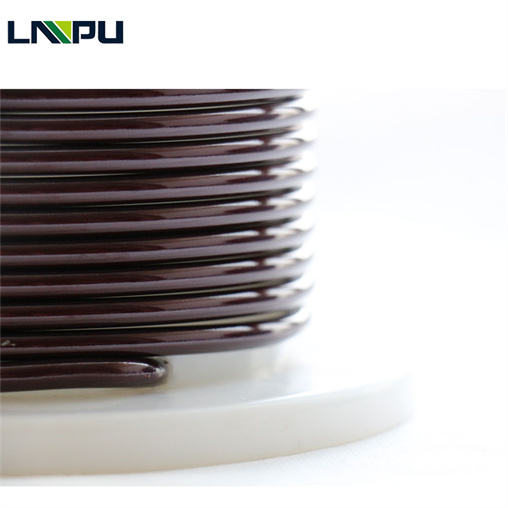

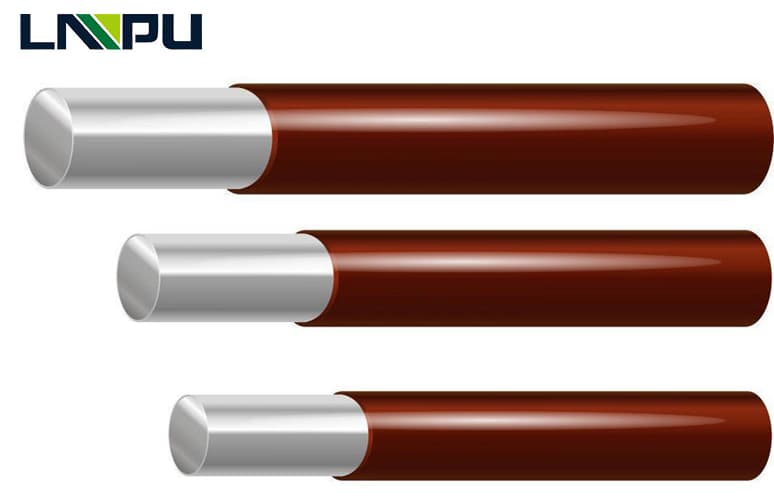

Dimension:0.2–10.0mm,

Rectangular: A> 0.8–8mm, B> 2-22.5mm

Square: 0.4*0.4mm–8*8mm

Foils:Thickness£º0.2–2.5mm, width:60–1250mm

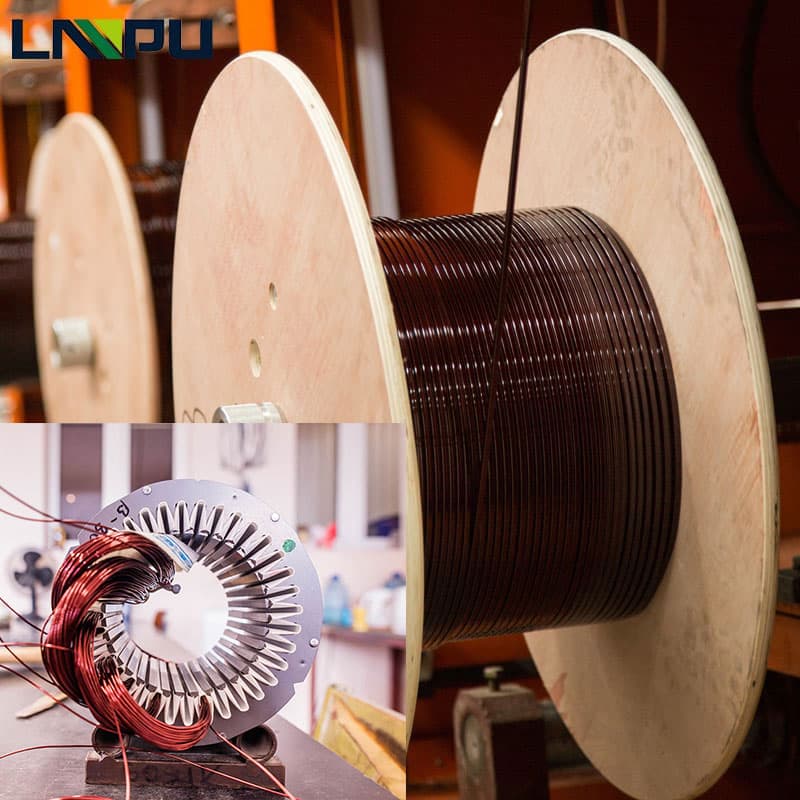

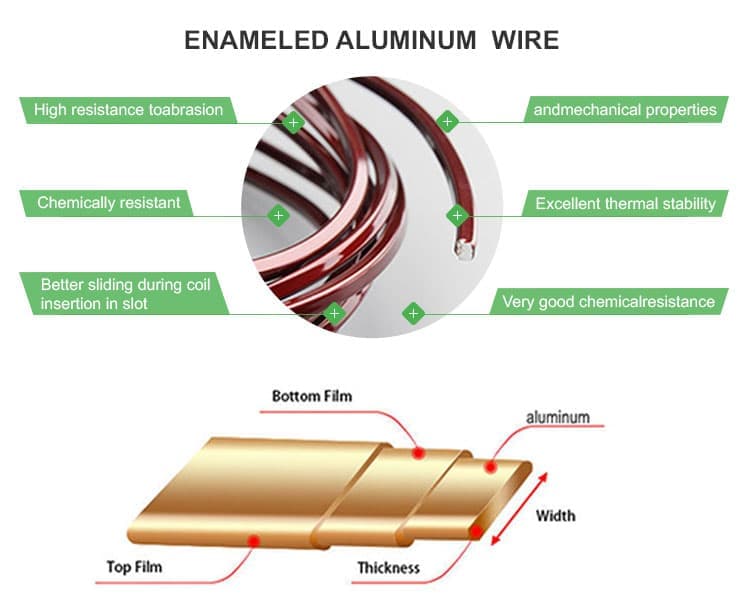

Application: used for transformers, inductors, motors, generators, dry type transformer, Cast Resin Transformers

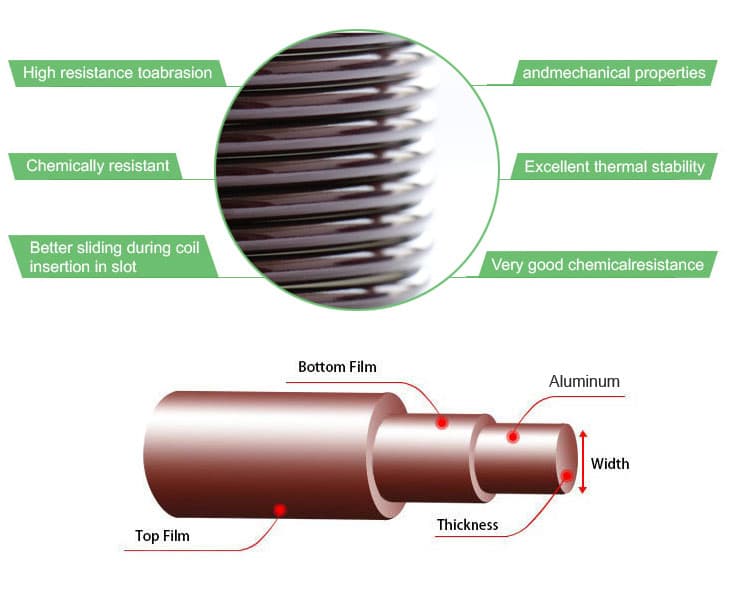

Because the mechanical strength and tensile resistance of aluminum wire are lower than copper wire, the traditional enameled aluminum wire is likely to cause wire breakage when winding. In order to improve the tensile resistance of enameled aluminum wire, current manufacturers Generally, enameled wire paint with higher hardness and toughness is applied to the surface of aluminum wire to improve the overall mechanical properties of the enameled aluminum wire. Although this method can improve the mechanical properties of enameled aluminum wire, the use of high-quality paint film will increase the production cost of enameled aluminum wire, thereby reducing the cost of enameled aluminum wire compared to enameled copper wire. The economic advantage of this makes buyers more inclined to use enameled copper wire. Therefore, the existing enameled aluminum wire cannot simultaneously have the characteristics of low production cost and good tensile performance.