Mechanical properties of enameled winding wire

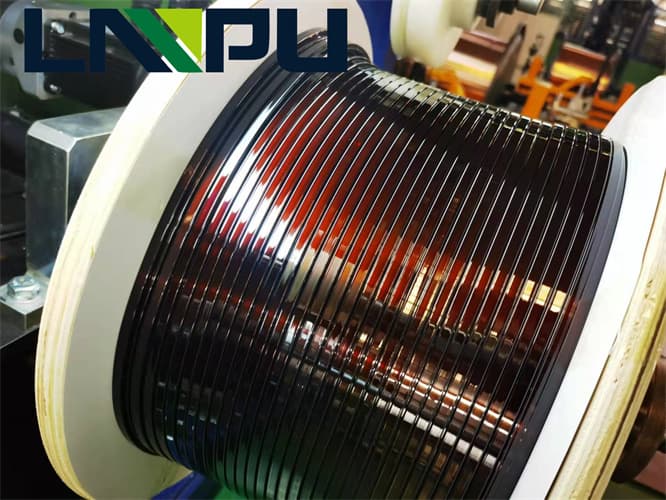

3.1 Elongation:

The standard refers to GB/T6109, inspection method: stretch the instrument

Calculation method: ratio of (length after stretching-length before stretching)/length before stretching;

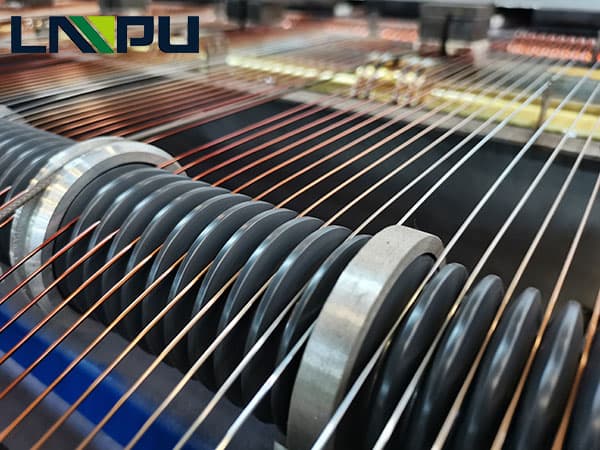

3.2 Snap off:

The standard is to pull at a speed of 2 meters per second to check that the paint film is not cracked,

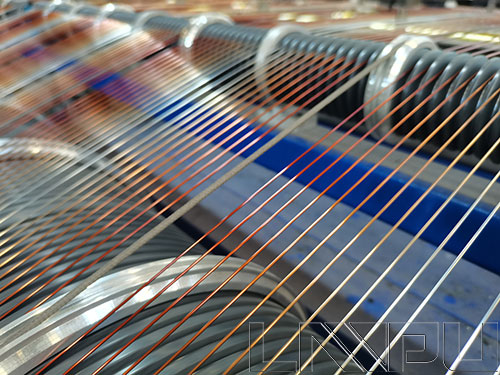

3.3 Round rod winding:

Wrap the enameled wires of different specifications and the corresponding copper rods around ten times to check that the paint film is not cracked. The diameter of the copper rods refers to the requirements of GB/T6109;

3.4 Thermal shock: Put the winding enameled wire in an oven (hanging in the middle of the oven) for 0.5 hours. The temperature of the oven corresponds to the specification requirements of the enameled wire. Refer to GB/T6109. After the drying, check that the paint film is not cracked.