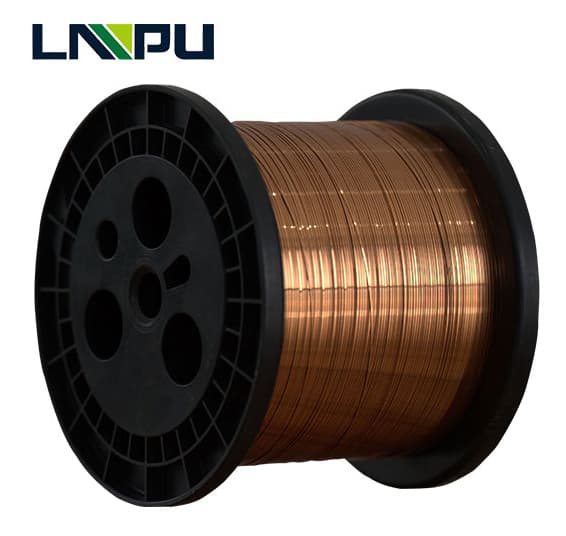

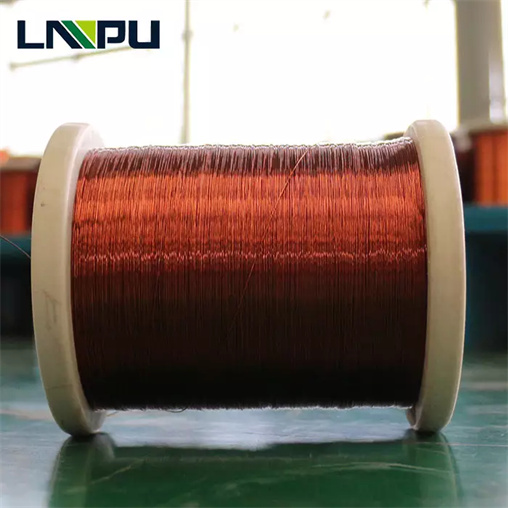

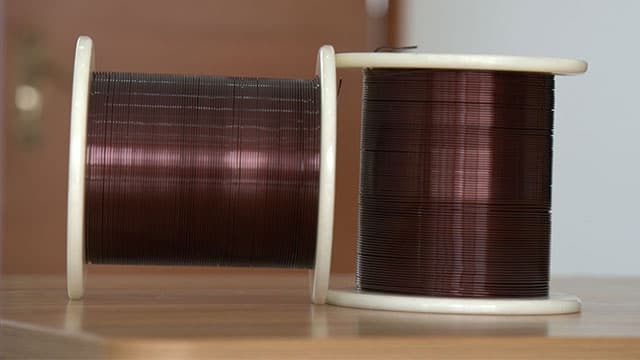

Kapton Insulated Copper Wire For Oil Immersed Transformer

Kapton Insulated Copper Wire For Oil Immersed Transformer has heat resistance, excellent chemical stability, high temperature resistance, toughness, abrasion resistance, flame retardancy, electrical insulation, etc.

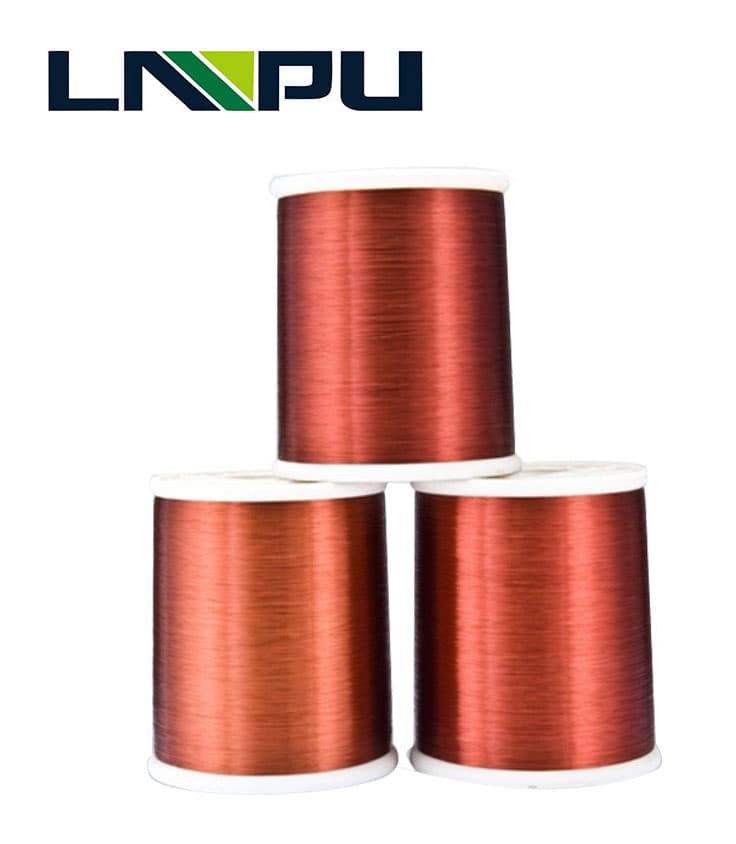

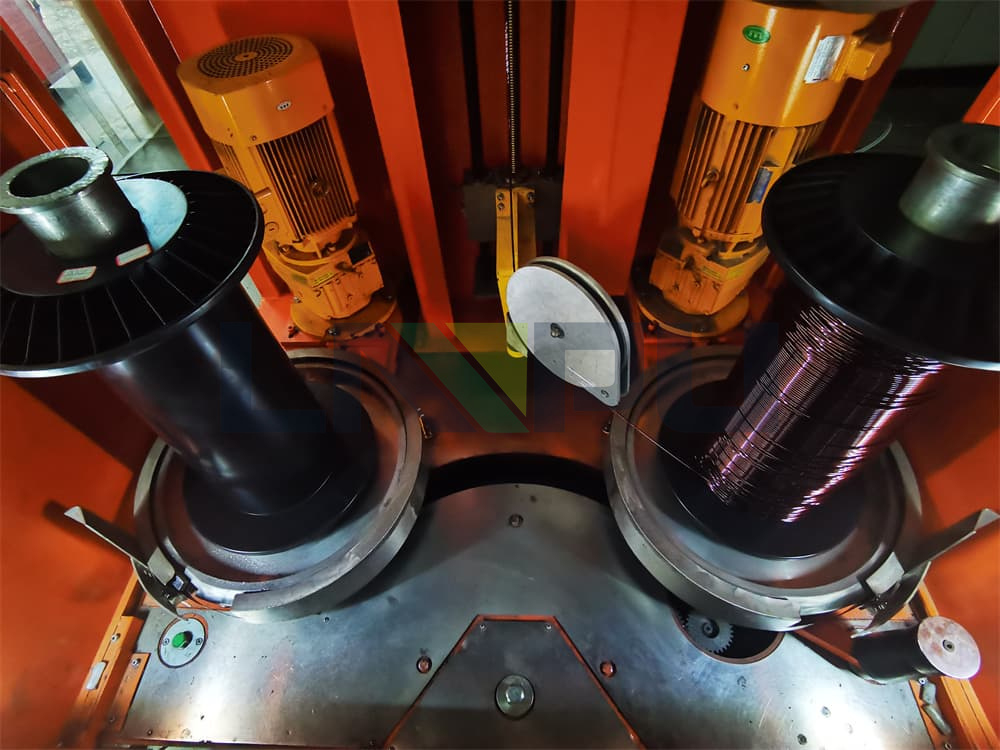

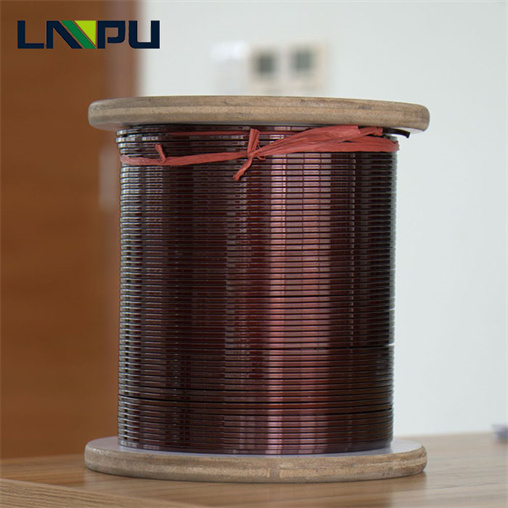

Kapton Insulated Copper Wire can be used as enameled wire paint, motor winding impregnating paint, etc. It is of great significance to the electrical industry. Enameled wire is an important material for small and medium-sized motors and electrical equipment. At present, the requirements for heat resistance and thermal stability of enameled wire insulation are particularly high. Because electrical equipment needs to operate at high temperatures. Improve the reliability of overload and increase the unit power of electrical equipment. The application of polyimide in this area can significantly improve the insulation capacity of the motor.

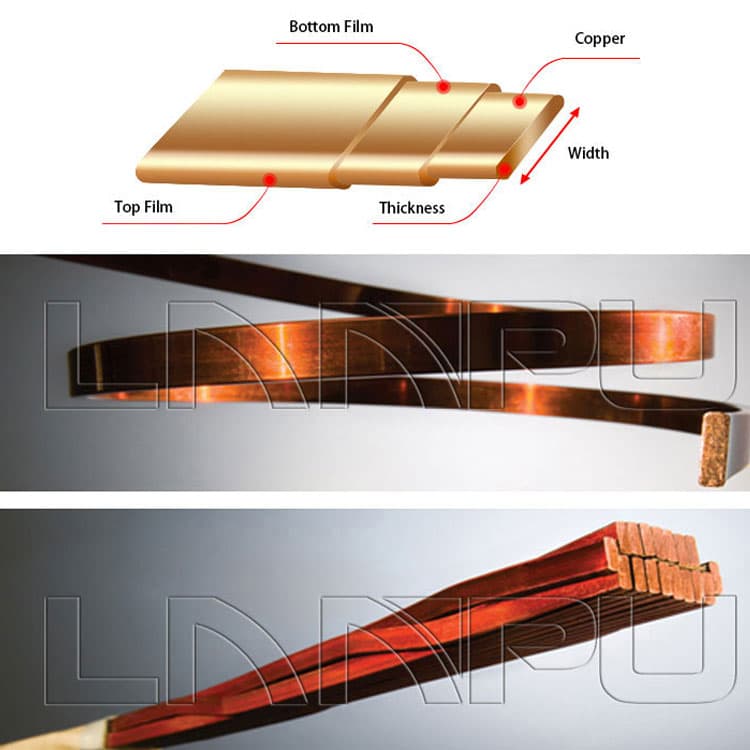

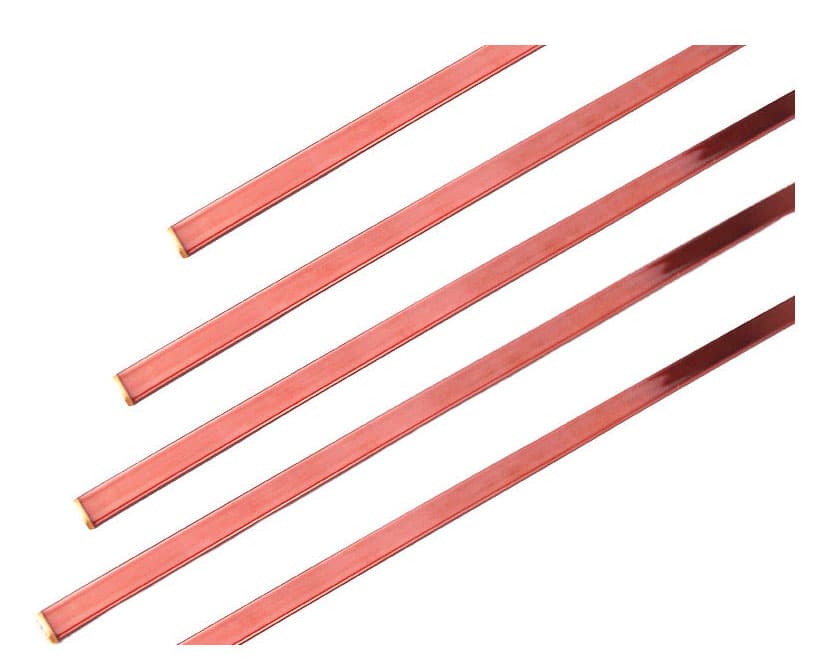

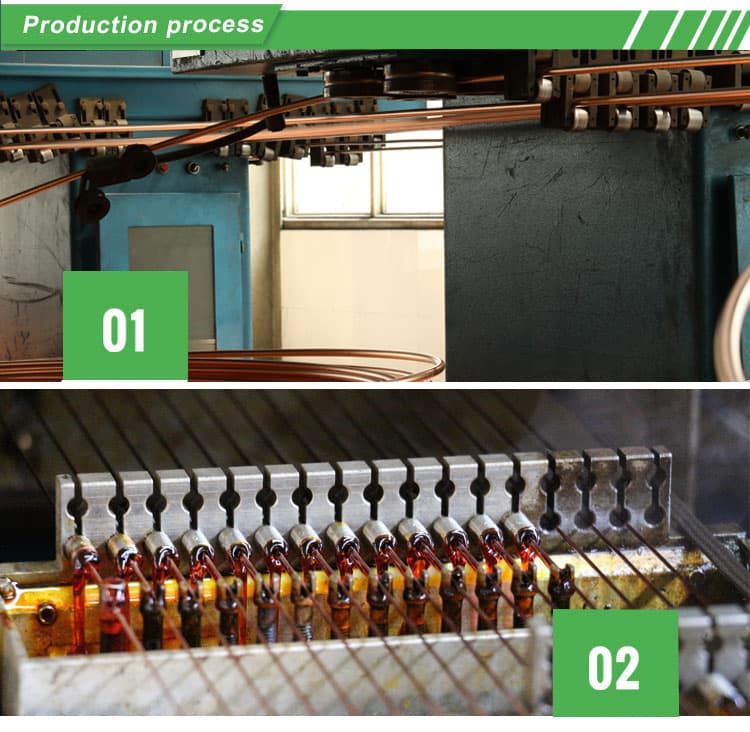

Insulation is a high mechanical strength Kapton Type-F film that is applied and heat treated to minimize trapped gases. Multi-conductor cables are available in either flat ribbon or circular configuration with an outer PEEK (polyetheretherketone) monofilament weave.

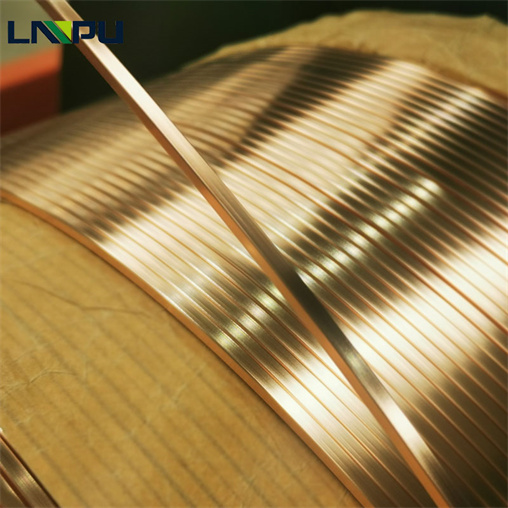

Kapton Insulated Copper Wire, the cross-section of the enameled wire is rectangular, and has a five-layer structure, the length of the rectangle is 1.2 to 1.3 times the width, including an aluminum alloy conductor core, and the outside of the aluminum alloy conductor core There is a copper coating layer, the outside of the copper coating layer is provided with a tin coating layer, the outside of the tin coating layer is provided with a polyimide paint layer, and the outside of the polyimide paint layer is provided with a thermally conductive silica gel layer , The thickness of the thermally conductive silica gel layer is 0.3-0.4 mm. Through the above method, the utility model has a simple and reasonable structure, good heat resistance, a rectangular cross section, and when used, the winding assembly is relatively compact and has good heat transfer and thermal conductivity.