Is the water quality effect on the production of the enameled wire?

Water quality affects the production of lacquer wires?

The production water production water in the lacquered wire has a variety of uses, and like, the requirements for water quality are also different. Depending on the purpose of use, the water quality can be divided into: annealing furnace water seal water, equipment cooling water, lubricant manufacturing water, etc.

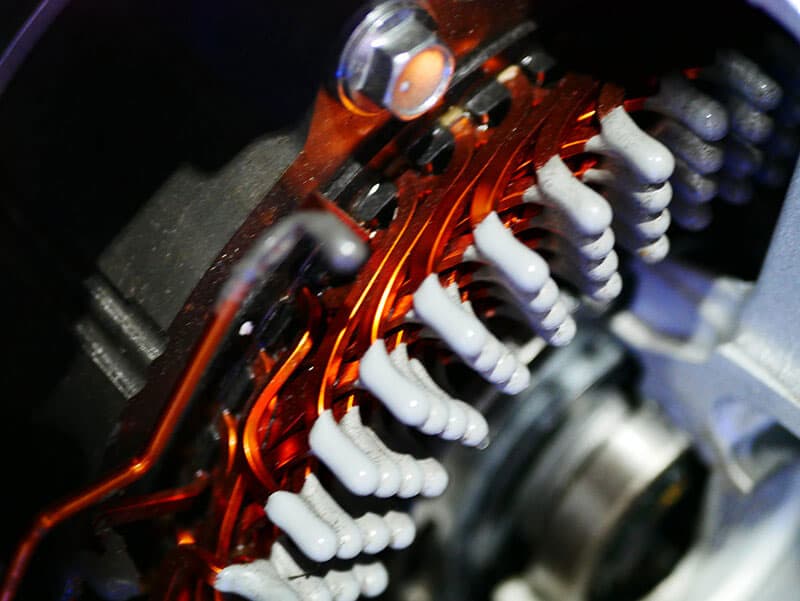

1, affecting the quality of the enameled wire.

During the production of lacquer wire, if the particles in the water remain on the copper wire, the surface of the copper wire is not straight, and the small holes; the pollution of ionic impurities will increase the surface charge density of the copper wire, resulting in oxidation Laminated chemical properties decreased, which affects its parameters. During the stretching, these impurities are adsorbed onto the copper wire, which will spread to the inside of the copper wire, affecting the surface lubrication of the copper wire, causing partial resistance uneven, and is easy to break through the disadvantages, and because of the oil or organic substance in water, affect Painting, the paint film adhesion is poor, resulting in a decrease in air hole insulation parameters. In particular, the pollution of CL will occur due to the action of the tide, and the black spot in the climate of the humidity is the reason why the enameled wire black spots is, so the paint film is perforated, and the moisture is further invaded, causing the painting package wire quality parameters to decwire, this is also The reason for the voltage drop.

2, the impact on mechanical parts.

We know that during the transmission of the mechanical equipment, in order to ensure that the equipment continues to work at high speed, metal collisions, the equipment must be cooled. If the cooling water contains a large amount of impurities, it will seize: equipment pollution, corrosion, fouling, salting, pipewire exercise, fouling, fouling. The device cooling effect is lowered. The equipment is damaged, the maintenance pressure is increased, and the mechanical life is reduced, which will seriously affect the production power and economic benefits of the equipment.

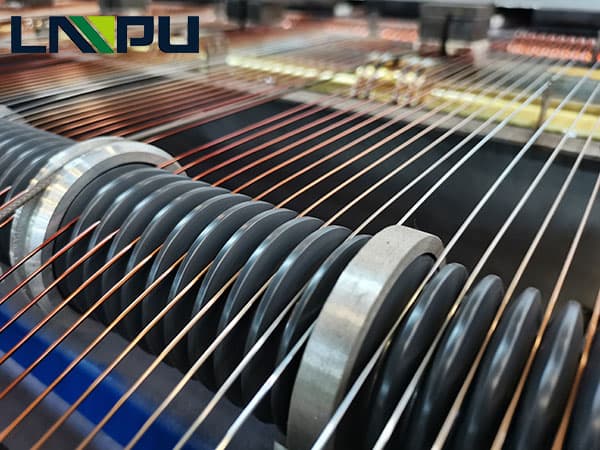

For the clogging of the annealing furnace annealing tube encountered in the production of lacquered wires, the surface of the invasive guide wheel is related to the accumulation of calcium magnesium ion in hard water.

3, the effect of lubrication.

Because of impurities in water, especially hardness ingredients, a chemical reaction with an alkawire lubricant will consume a large amount of lubricant, which is reduced, and the effect is lowered and accelerated. Therefore, many manufacturers use pure water during the production of lubricants, the effect is very good.

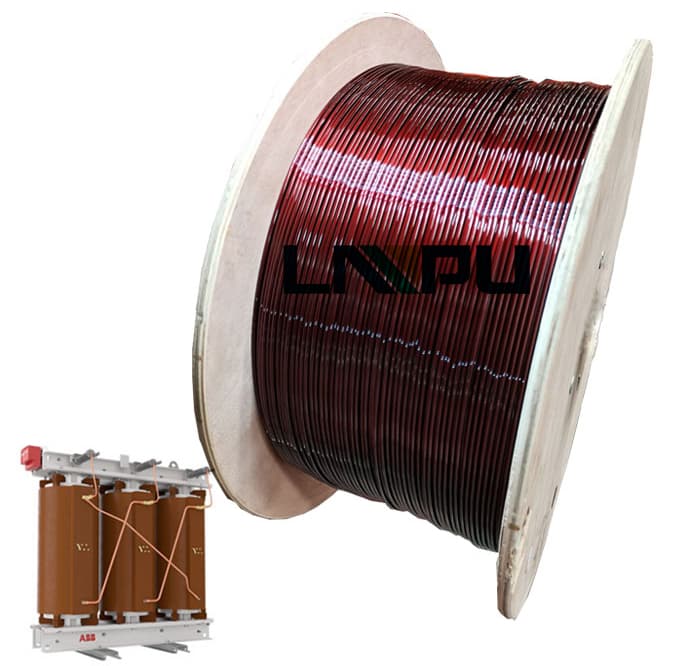

The water quality involving the product, cooling water (direct contact product) is strictly controlled, the higher the diameter of the thin wire. Mainly controlled by the following levels:

(1) Painted wire, copper wire annealing water seal: conforming to primary distilled water specification, the conductivity is 10 / cm, no CL detection, no hardness.

(2) Mechanical cooling water: soften water.