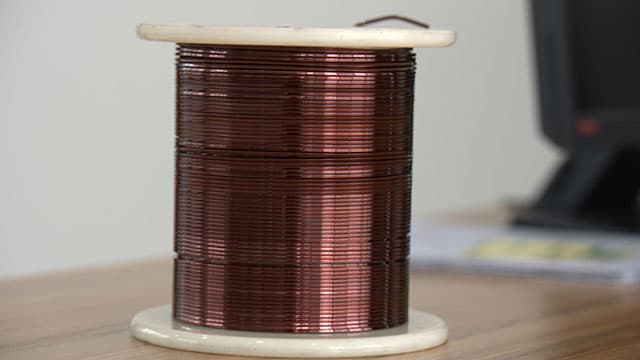

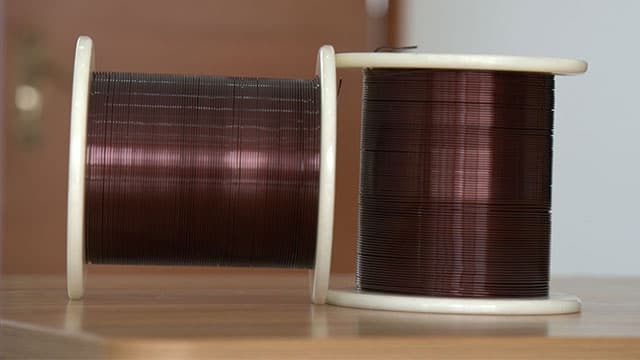

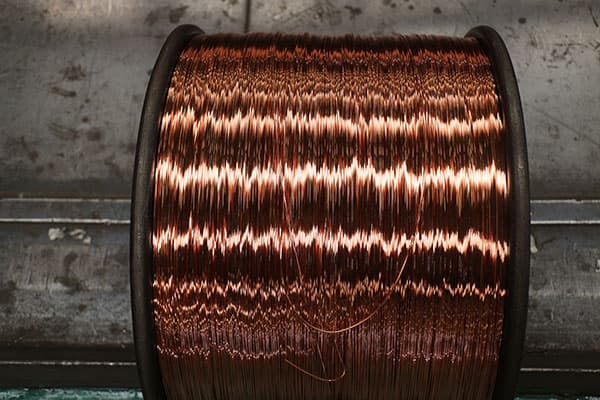

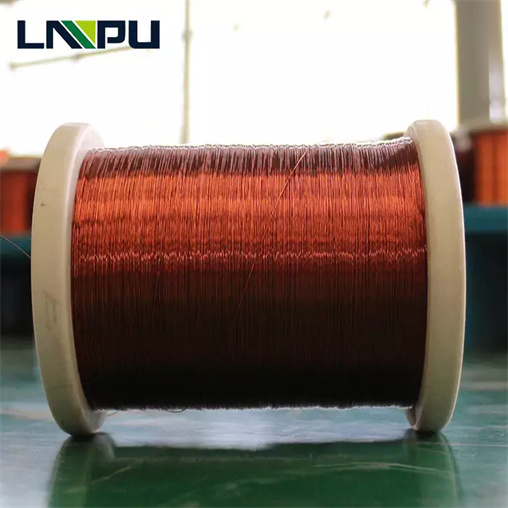

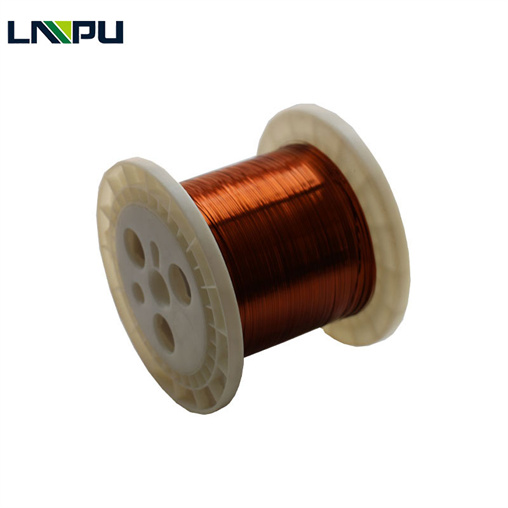

Insulated Nylon Coating Submersible Motor Copper Winding Wire

Insulated Nylon Coating Submersible Motor Copper Winding Wire

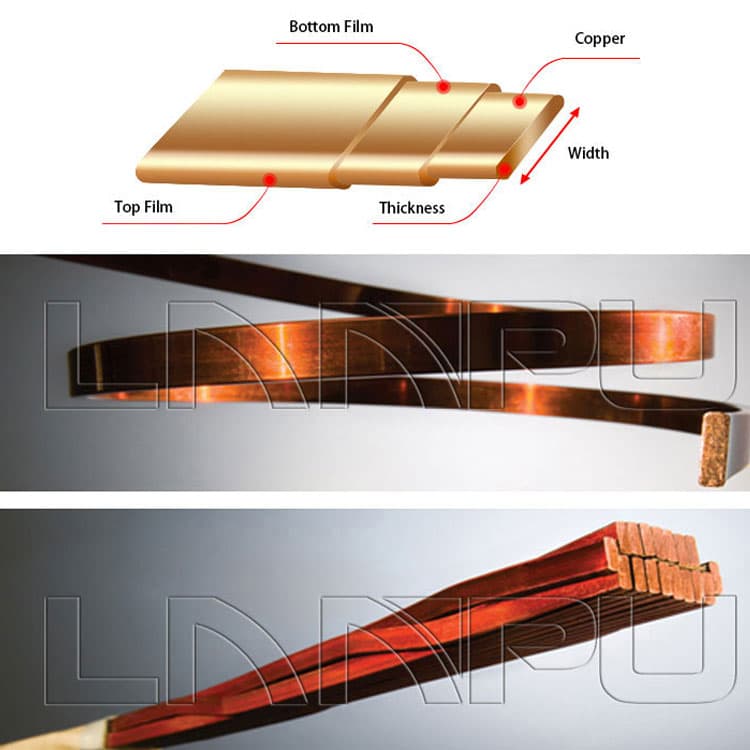

1.Nylon coated polyurethane enameled copper wire (UEW+NY),

2. Polyester enameled copper wire coated with nylon (PEW+NY),

3. Nylon hot melt enameled copper wire (NFW)

Used for motors and coils, relays, fractional horsepower motors, dry-type transformers and sealed coils.

1. Nylon coated polyurethane enameled copper wire (UEW+NY)

Temperature resistance and so on: 130-155 degrees

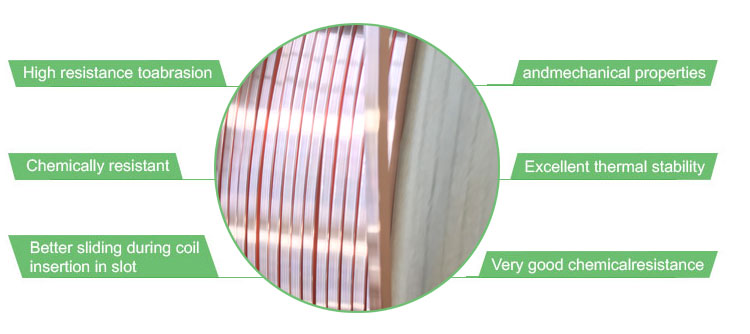

Insulation description: UEW+NY is a double-layer weldable insulation layer. The nylon outer density wire can reduce winding friction, reduce the volume rate and help fast winding.

characteristic:

(A) Excellent winding linearity during high-speed winding or self-winding.

(B) Can provide coils and windings with higher production density.

(C) It has good ¡®Q¡¯ value (quality factor) characteristics at high frequencies.

(D) Good solvent resistance. It has good resistance to solvents and hardeners commonly used for impregnation with varnish.

Applications: Relays, ignition coils, miniature transformers

2. Polyester enameled copper wire coated with nylon (PEW+NY)

Extreme temperature resistance: 155 degrees

Insulation description: PEW+NY is a typical double-layer insulation structure, and its temperature resistance and mechanical properties are better than PEW wire types.

characteristic:

(A) It has the winding linearity of chicken frame, good wear resistance, suitable for high-speed winding or automatic winding

(B) It has good temperature resistance and mechanical properties.

Applications: motors and coils, relays, fractional horsepower motors, dry-type transformers and sealed coils.

3. Nylon hot melt enameled copper wire (NFW)

Extreme temperature resistance: 105 degrees

Insulation description: The insulating layer of NFW is nylon series hot-melt polyamide resin. It is designed to melt the film at a constant temperature, so that the coil will fuse to protect the coil from burning when it is overloaded.

characteristic:

(A) It has a fire insurance function under load. When the operating temperature surges to about 200 degrees, the film automatically melts, which will cause the copper wire to fuse due to the surge in the current in the circuit. There is an NFW wire transformer away from it, which will prevent ignition from burning. .

Applications: Transformers for household appliances, etc.