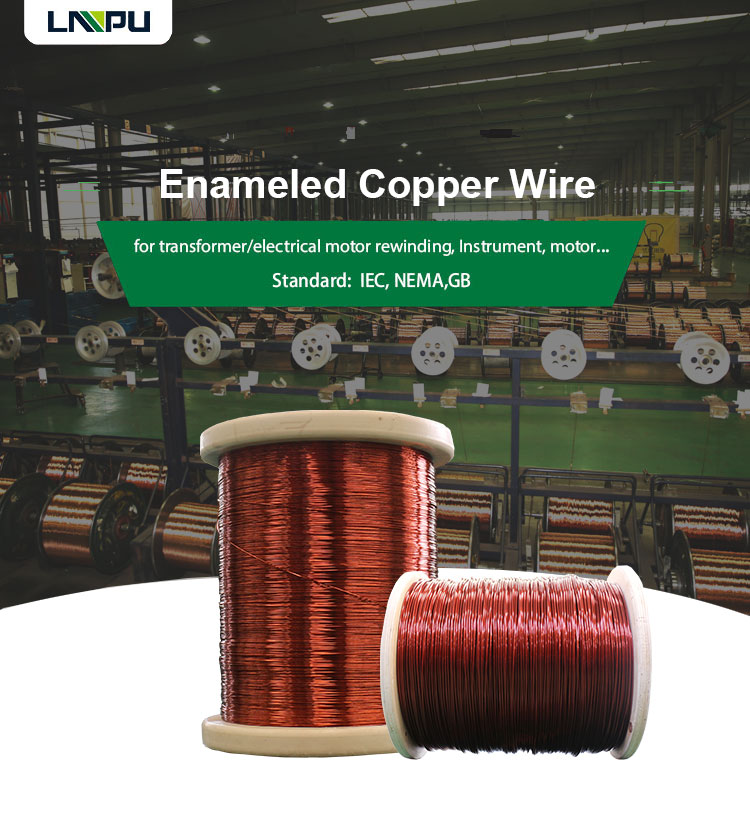

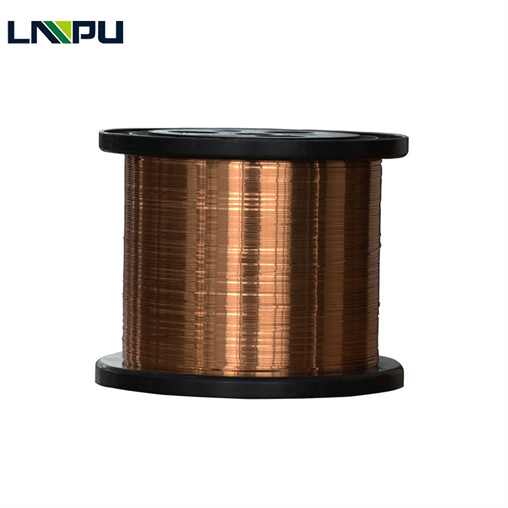

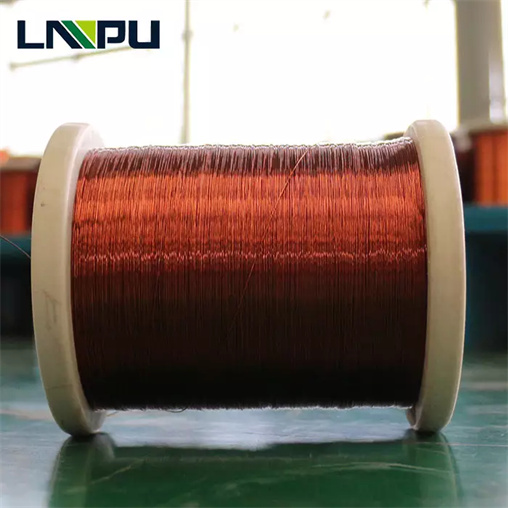

IEC Standard High Thermal Class 180 200 220 Enameled Copper Round Wire

IEC Standard High Thermal Class 180 200 220 Enameled Copper Round Wire

Straight welding modified polyurethane enameled copper wire (SEIW)

Polyesterimide enameled copper wire (EIW)

Amide-imide coated polyester enameled copper wire (EAIW)

Polyimide enamelled copper (AIW)

Used for High-voltage coils, relays, transformers, hand machine motors, electronic coils, Motors, steam coils, dry-type transformers, hand tool armatures, cold coal compressors, etc.

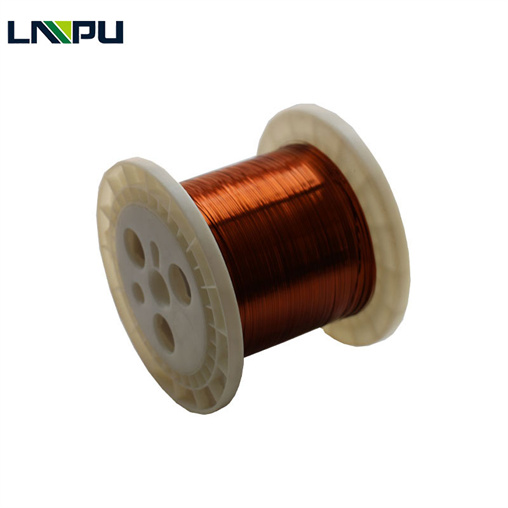

1. Polyesterimide enameled copper wire (EIW)

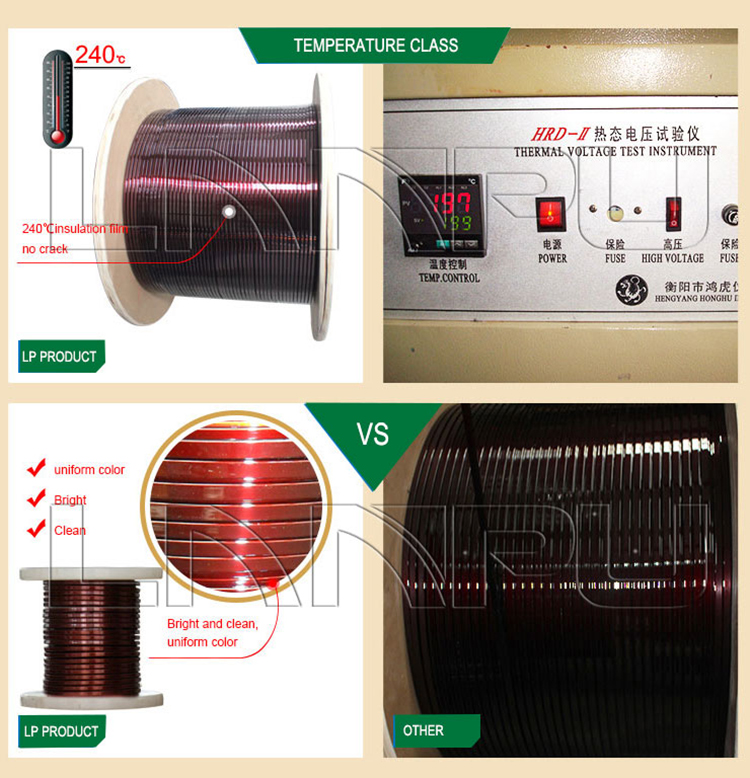

Temperature tolerance: 180 degrees

Insulation description: EIW has good temperature, stability and insulation characteristics when it is operated continuously at 180 degrees.

characteristic:

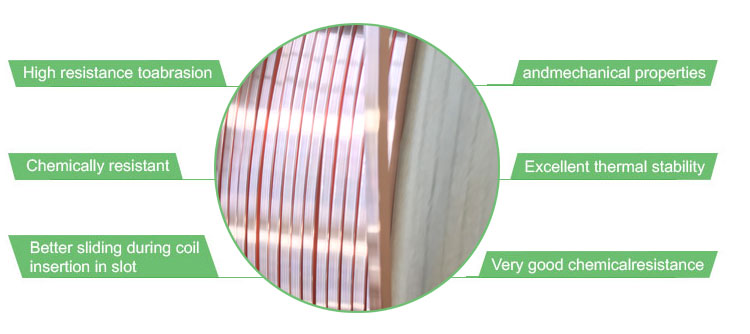

(A) Good film adhesion, heat resistance and chemical resistance.

(B) It has good insulation properties and corona resistance

Application range: motors, micro motors, transformers, relays, enclosed motors, hand machine motors, fractional horsepower motors, integral motors.

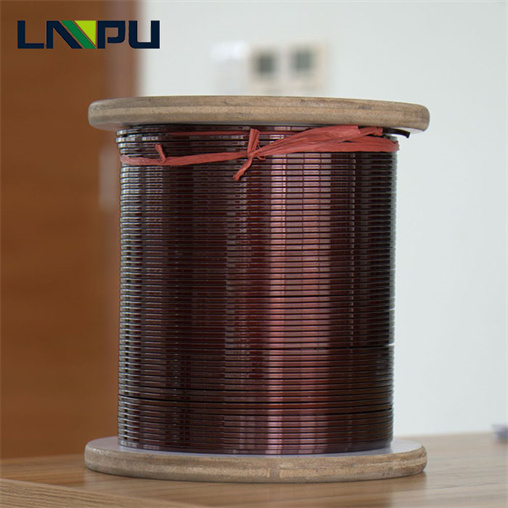

2. Amide-imide coated polyester enameled copper wire (EAIW)

Temperature resistance etc.: 200 degrees

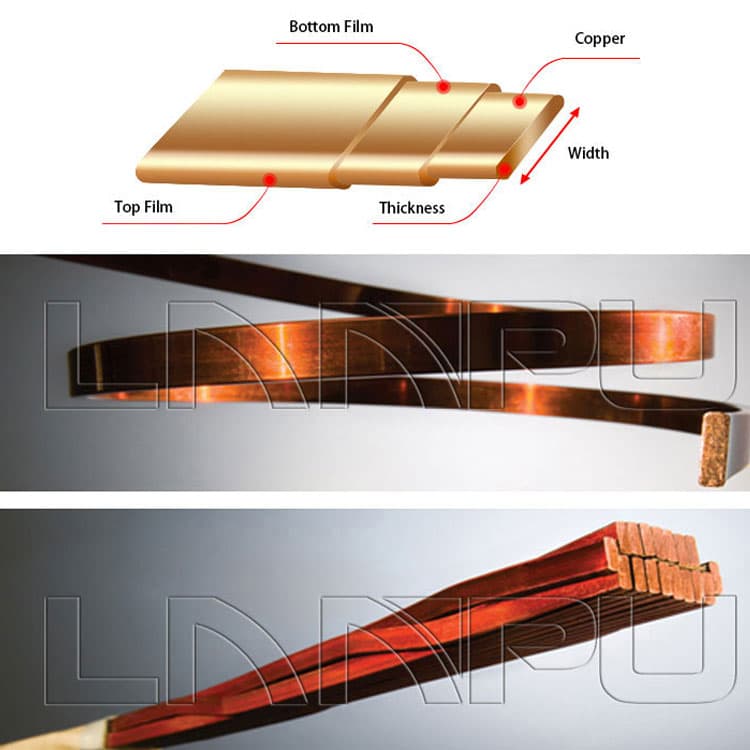

Insulation description: EAIW is a double-layer insulation layer. This combination improves the insulation properties to obtain the best properties, such as tough physical properties and excellent insulation, excellent chemical resistance, and cold coal resistance.

characteristic:

(A) Compared with PEW+NY, it has better heat resistance, moisture resistance and chemical resistance.

(B) EAIW provides Qijia’s maturity resistance.

Applications: Motors, steam coils, dry-type transformers, hand tool armatures, cold coal compressors.

3. Polyimide enamelled copper (AIW)

Temperature resistance and so on: 220 degrees

Insulation description: AIW has excellent temperature resistance, mechanical resistance and chemical resistance, and is designed to withstand the harshest use environment.

characteristic:

(A) Good chemical resistance, compatible with most of the dissolving and impregnating varnish.

(B) Excellent wear resistance, suitable for the most stringent winding forming process.

(C) It has excellent adhesion and heat resistance characteristics.

Applications: automotive coils, hand machine motors, motors, dry-type transformers, high-load motors, etc.

4. Straight welding modified polyurethane enameled copper wire (SEIW)

Temperature resistance and so on: 180 degrees

Insulation description: SEIW’s insulation composition is modified polyurethane, which is designed for direct welding and winding combinations with higher heat resistance. Its particularly high temperature index has better thermal performance than traditional direct welding paint.

characteristic:

(A) Excellent heat resistance and chemical resistance.

(B) The physical characteristics are suitable for most coils.

(C) It can be welded directly at 450-510 degrees.

Applications: High-voltage coils, relays, transformers, hand machine motors, electronic coils, etc.