How to weld enameled wire?

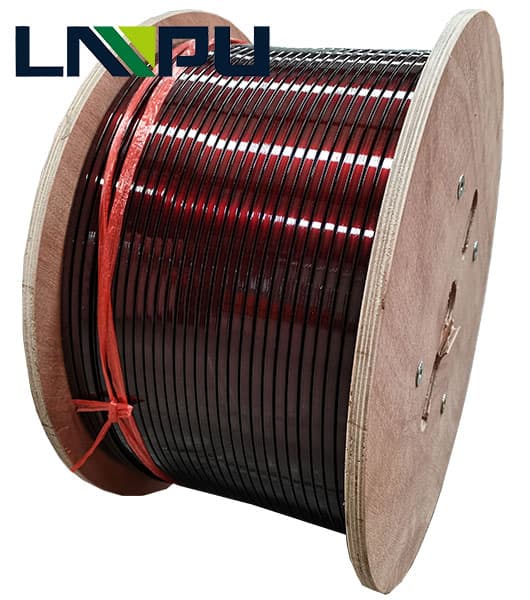

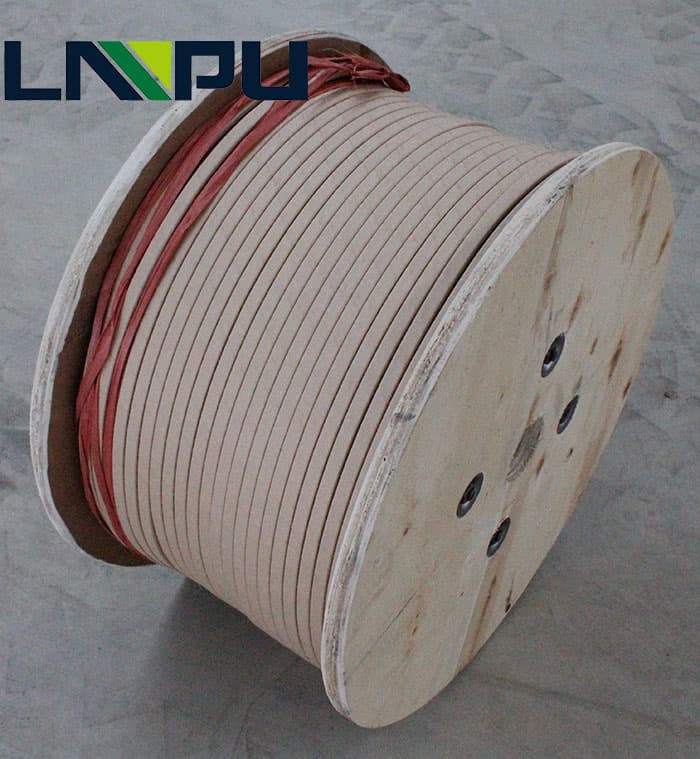

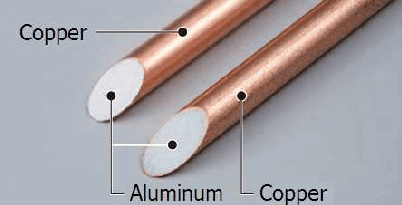

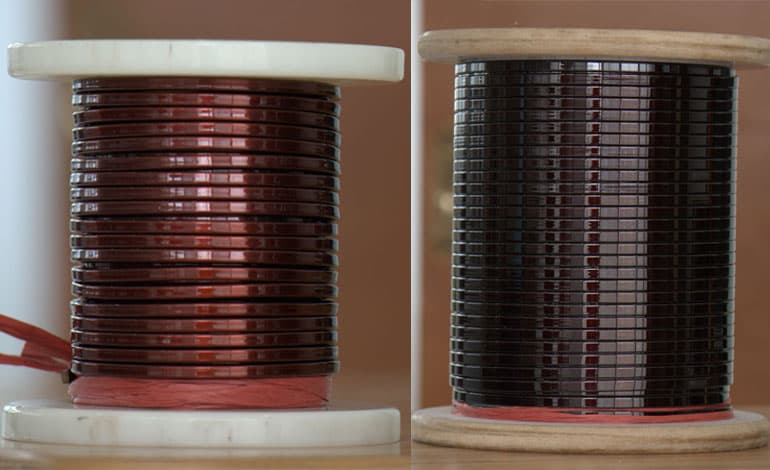

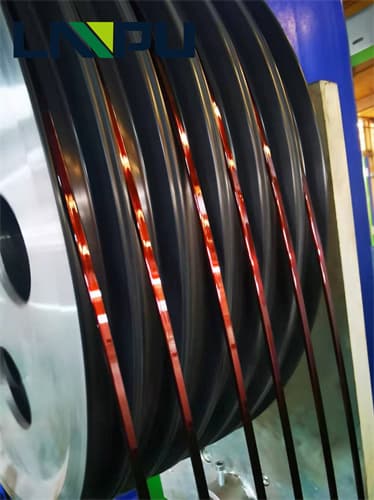

Enameled wire is a main type of winding wire. It is composed of a conductor and an insulating layer. After the bare wire is softened by annealing, it is painted and baked many times.

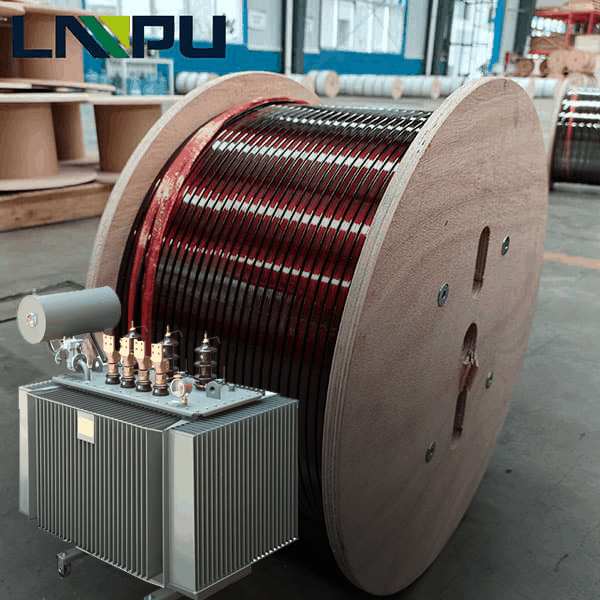

General purpose enameled wire (ordinary wire): Mainly used for winding wires in general motors, electrical appliances, instruments, transformers, etc., such as polyester enameled wire and modified polyester enameled wire.

Heat-resistant enameled wire: Mainly used for winding wires in working places such as motors, electrical appliances, instruments, transformers, etc., working in a temperature environment of 180¡æ and above, such as polyester imide enameled wire, polyimide enameled wire, polyester enameled wire, polyester imide /Polyamideimide composite enameled wire.

Take the welding of enameled wire and U-shaped copper terminal (curved copper terminal) as an example

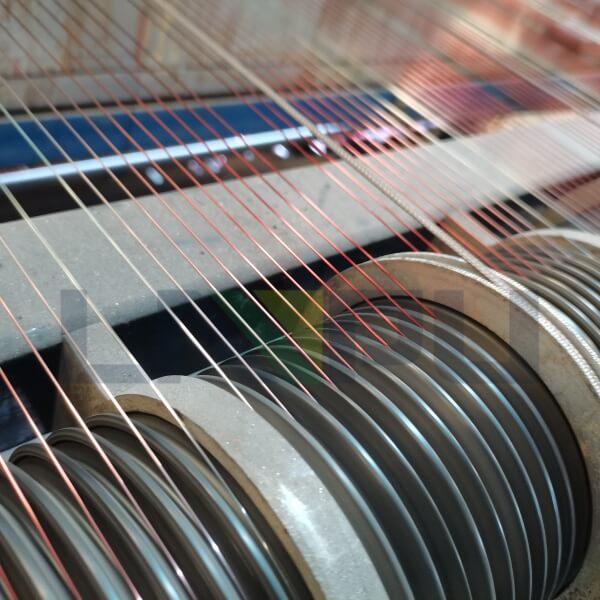

Traditional IF spot welding machine for welding:

Use intermediate frequency inverter DC spot welder for welding. The electrode presses the copper terminal, and uses the resistance of the copper terminal itself, the pressure exerted on the copper terminal and the large current that is conducted to generate Joule heat at the touch part of the workpiece. The heat mainly melts the paint, and the copper wire and copper after the paint is removed The terminal touch points are connected and welded with molten metal.

Difficulties encountered in this type of welding:

1. The enameled wire enameled leather needs to be completely exploded to eliminate the false welding that occurs when the enameled wire is not completely exploded; you can see the burnt of the enameled wire paint.

2. The deformation of the enameled wire needs to be controlled, and the deformation is not more than 1/3 to ensure that the enameled wire is not easy to break.

3. The requirements are specially set according to different structure products, electrode materials and shape requirements to ensure the welding effect;

4. Avoid exploding fire and avoid defective rate.

Use a hydrogen-oxygen flame welding machine to weld the coil lead wires of electronic devices such as motors, motors, and transformers.