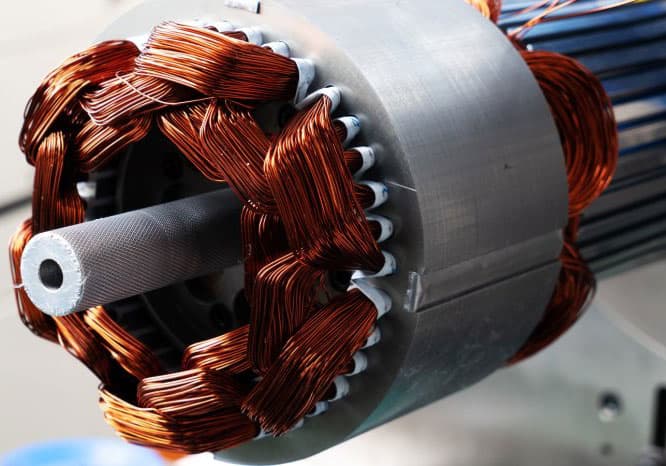

How To Distinguish High-quality Aluminium Magnet Wire?

Two method to Distinguish High-quality Aluminium Magnet Wire, one is size, the other is looking the appearance.

To purchase qualified aluminium magnet wire, before purchasing aluminium magnet wire, you can do the following two points:

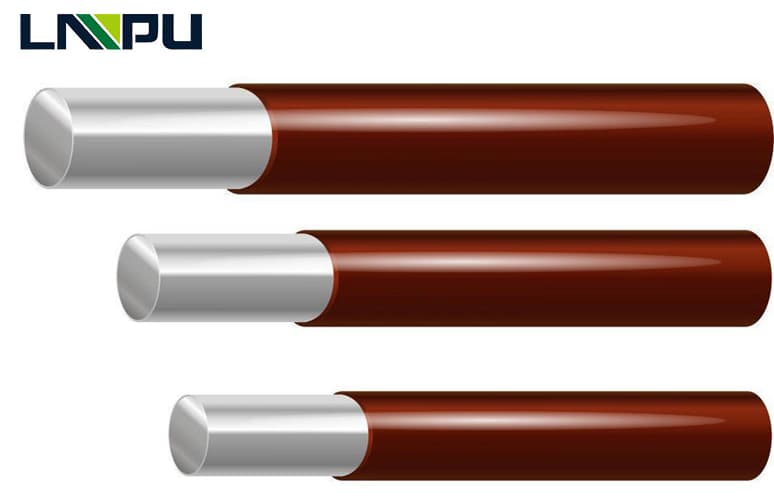

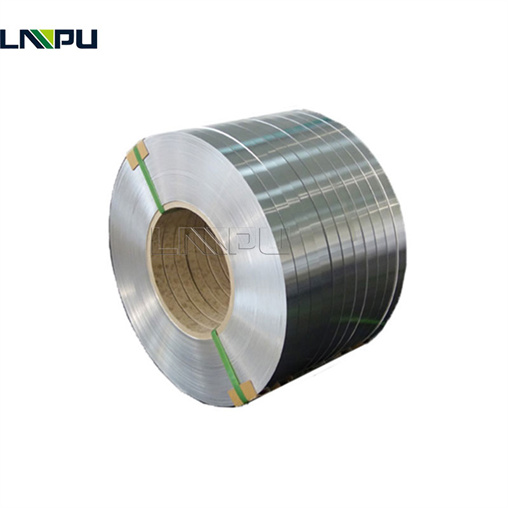

One, look at the size

The size of enameled round wire includes: external dimension (outer length) D conductor diameter d conductor deviation △d conductor roundness f paints film thickness t

The outer diameter refers to the diameter measured after the conductor is coated into an insulating paint film.

Conductor diameter; refers to the metal wire after removing the insulation layer

Conductor deviation; is the difference between the measured value of the diameter of the guide body and the nominal value.

The state value is the maximum difference between the maximum and minimum readings measured on each section of the guide body.

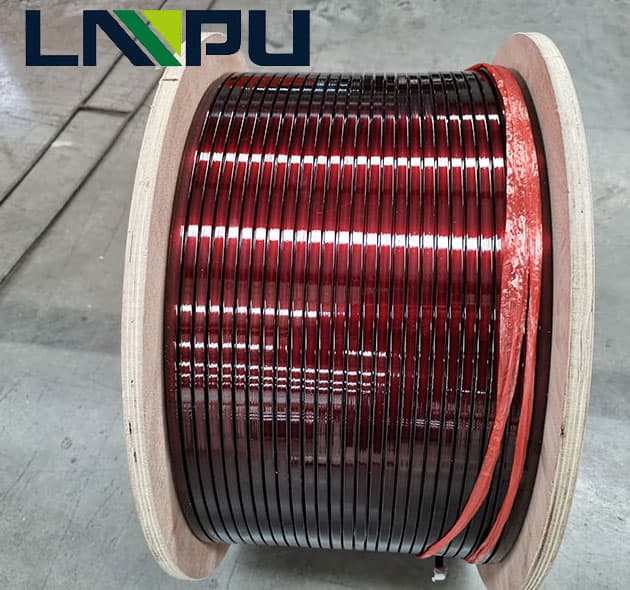

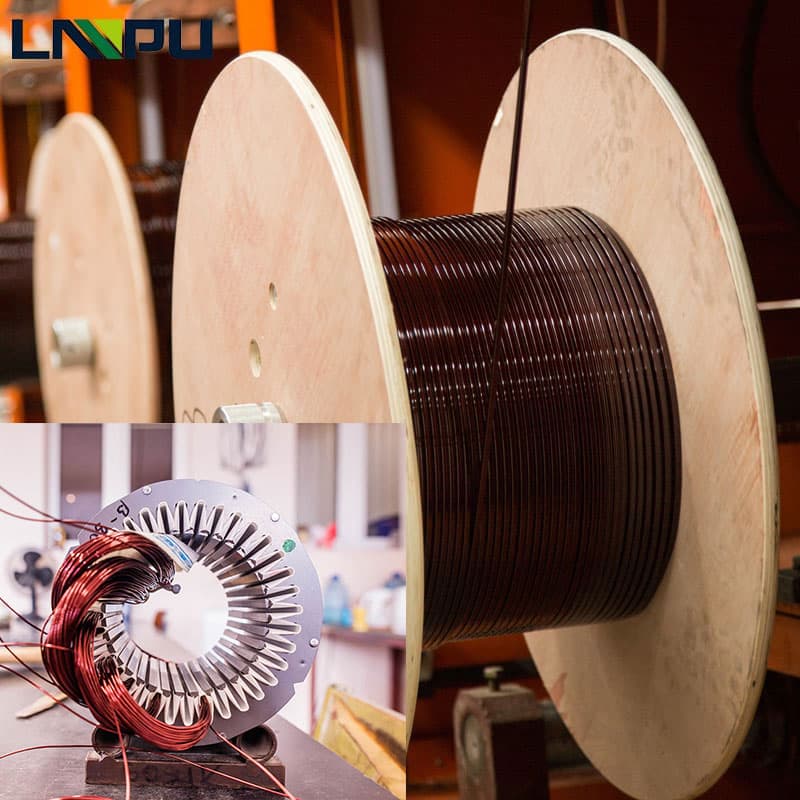

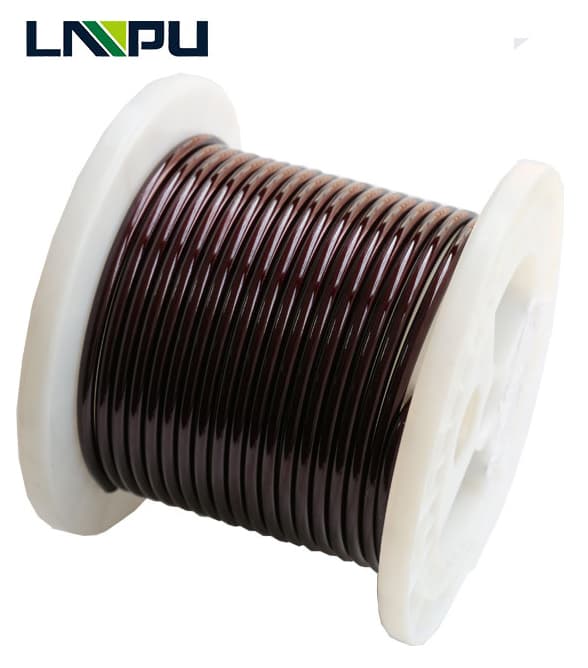

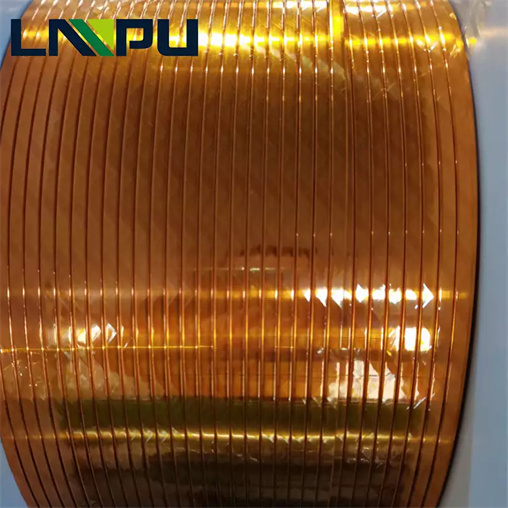

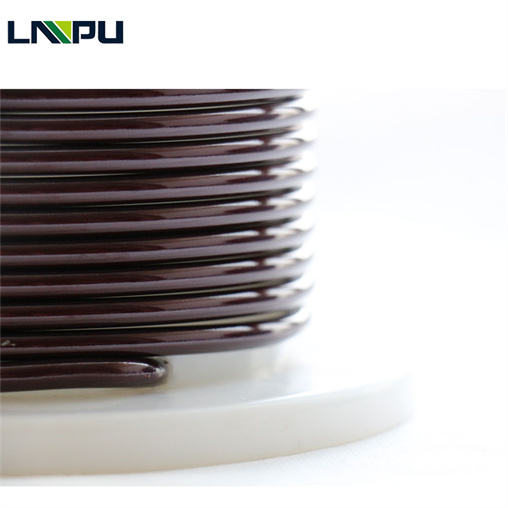

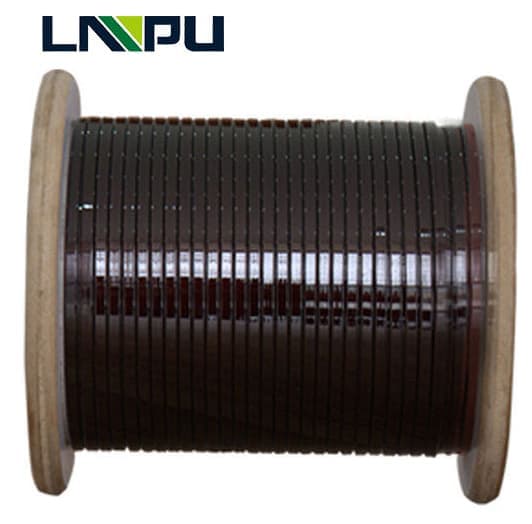

Second, look at the appearance

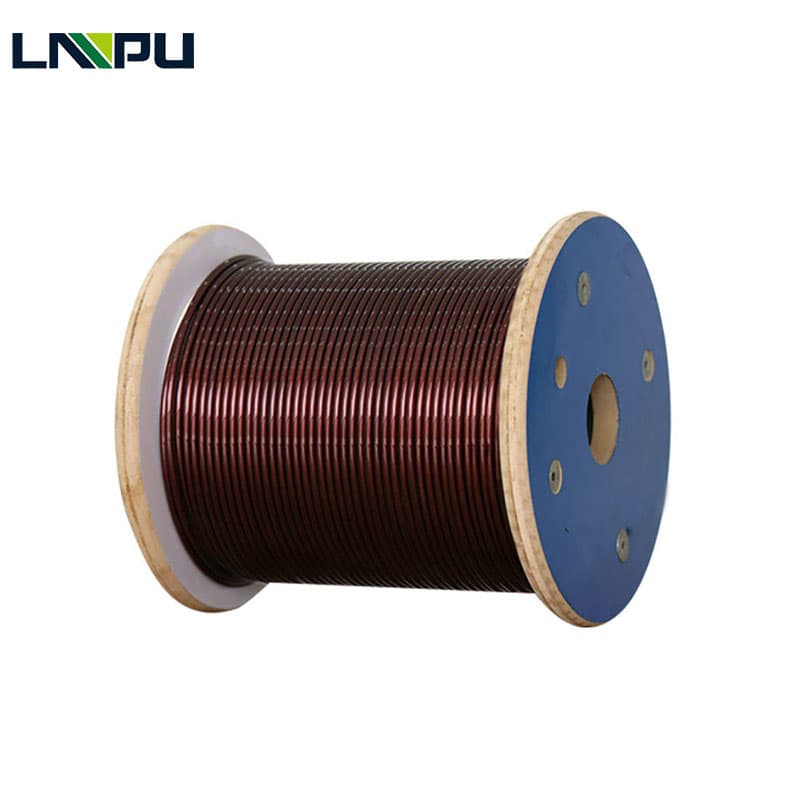

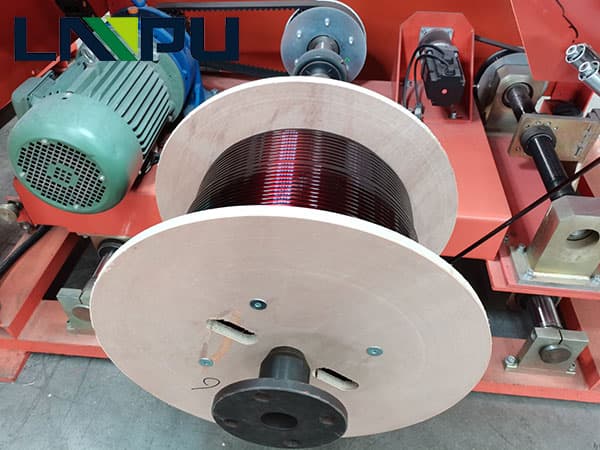

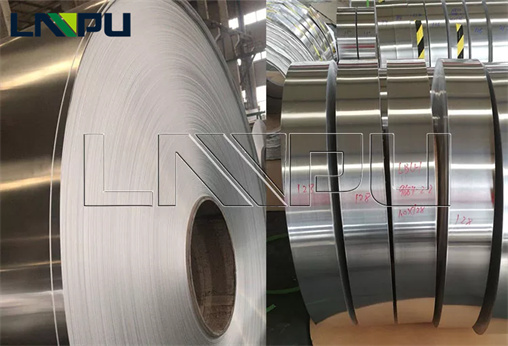

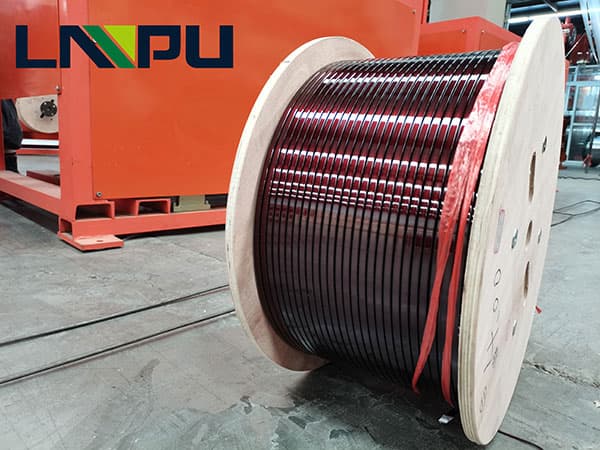

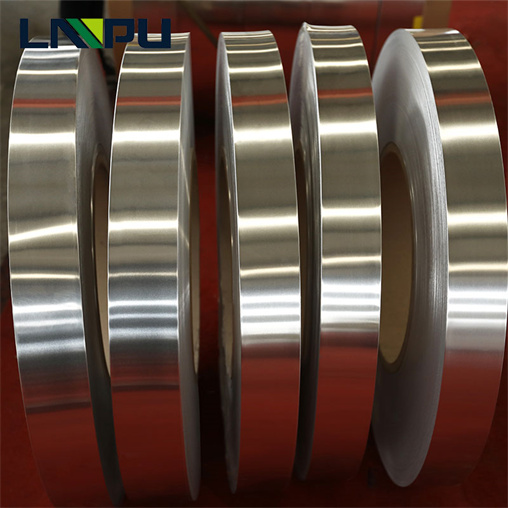

The surface of aluminium magnet wire should be smooth, uniform in color, no particles, no oxidation, hair, yin and yang, black spots, paint stripping, and other defects that affect performance. The cable should be neat, flat, and tight, and the ground should be wound on the wire reel of crimping. Many factors are affecting the surface, which is related to raw materials, paint, equipment, technology, environment, and other factors.