How to connect copper wire and aluminum wire?

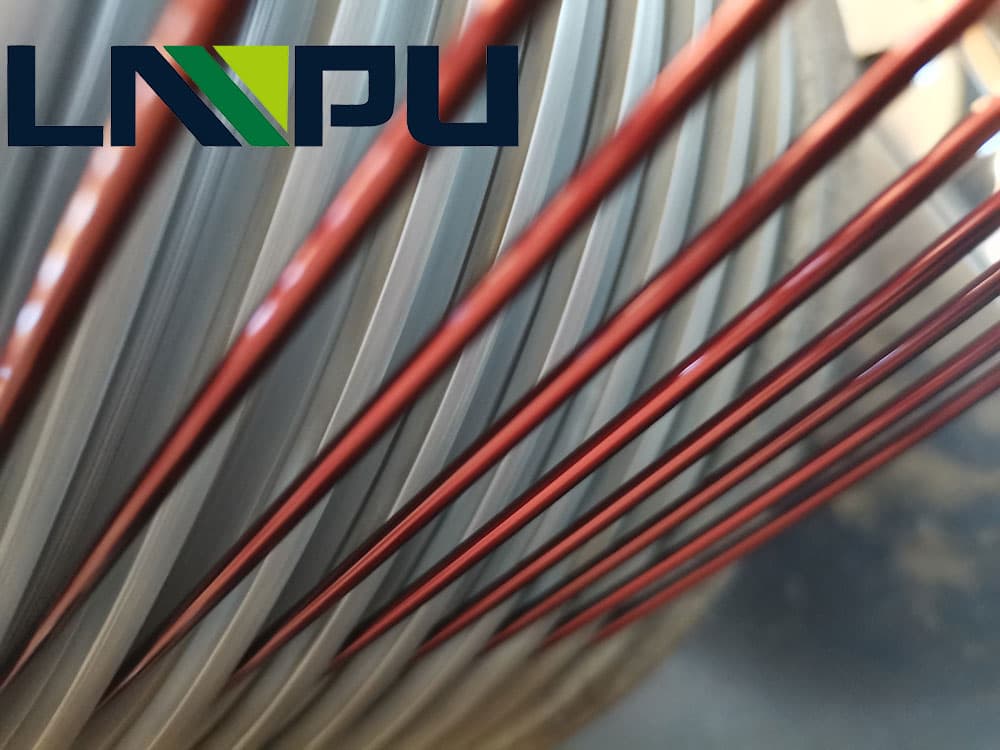

Aluminum wire is easy to oxidize in the air, forming a layer of oxide on its surface. In addition, aluminum is less hard than copper, which will greatly increase the contact resistance between the aluminum wire and the copper wire.

How to connect copper wire and aluminum wire

First, the resistivity of aluminum wire and copper wire are different;

Second, this is the most important thing, that is, aluminum wire is easily oxidized in the air, forming a layer of oxide on its surface, and aluminum is less hard than copper, which will greatly increase the connection between aluminum wire and copper wire. The contact resistance, when the current passes through this connection, the contact resistance will heat up. If it is a large current, the heat will be very serious and the connection will be burned.

Third, in accordance with safety operating regulations, aluminum wires cannot be connected to copper wires.

(1) The copper wire is connected to the aluminum wire, and electrical corrosion will occur at the connection. Generally, the aluminum wire is corroded first, causing the lack of phase and power failure to damage the electrical equipment. This is corrosion caused by the electrochemical reaction of two different materials. If there is no copper-aluminum joints, you can use copper joints for copper wires and aluminum joints for aluminum wires, but never connect directly. Be sure to fill a layer of zinc in the middle as a transition layer, because copper-zinc does not produce electrical corrosion, and aluminum-zinc is also There is no electric corrosion, which solves the problem of electric corrosion of copper and aluminum.

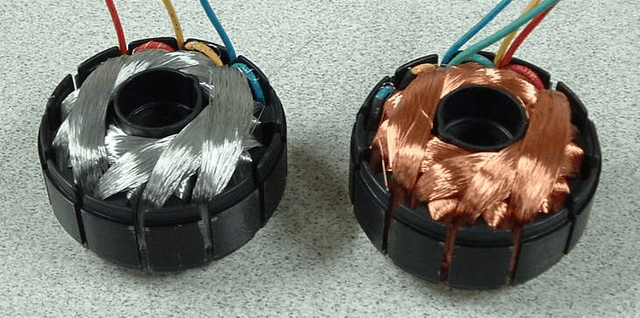

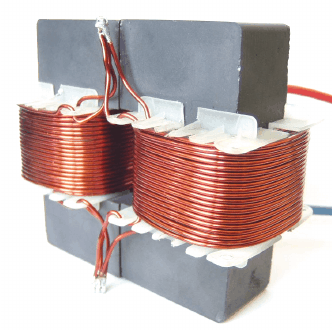

(2) Copper-aluminum joints: one end is a copper joint and the other is an aluminum tube. In the past, it was made by fusion welding on a copper-aluminum extrusion butt welding machine. Now there are advanced copper-aluminum flash butt welding machines for fusion welding. Of course there are other processes.

(3) After fusion welding, the molecular structure has changed. The aluminum has no longer lost electrons, so the galvanic corrosion phenomenon is eliminated.

Solution: (Because the external line is live, the operation needs to be extra careful)

1) Riveting the aluminum wire and copper wire together with riveting;

2) The aluminum wire and the copper wire are welded together by soldering;

3) The best thing is to replace the incoming wire with copper wire.