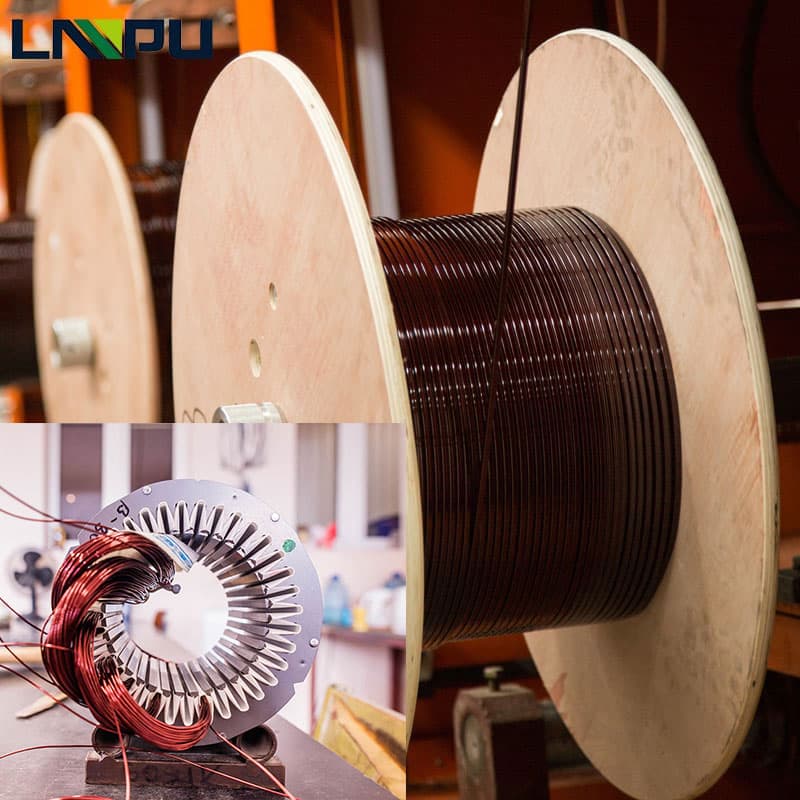

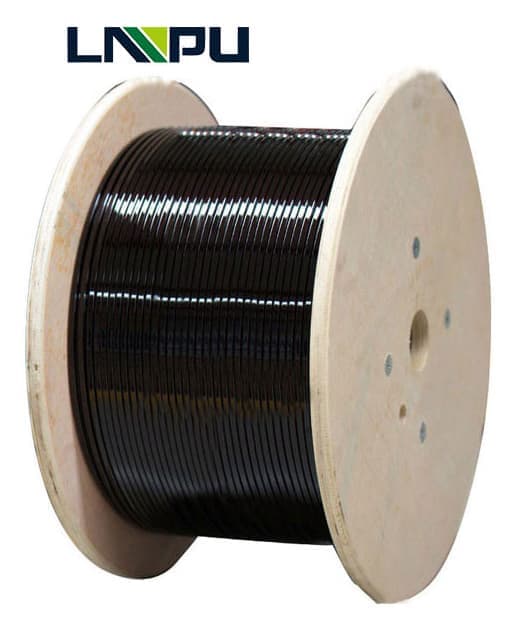

Hot Sale New Arrival Excellent Enameled Round Aluminum Wire 0.1-6.0Mm

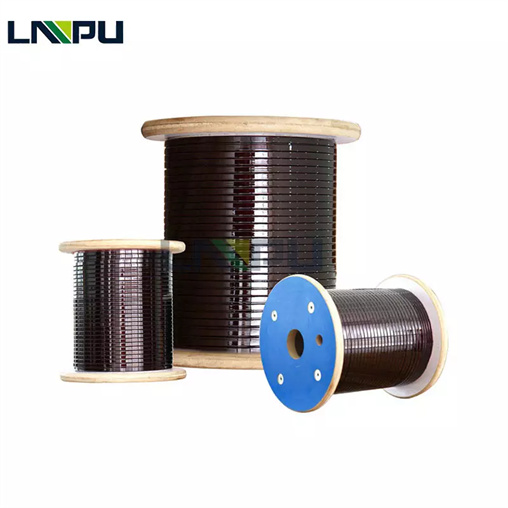

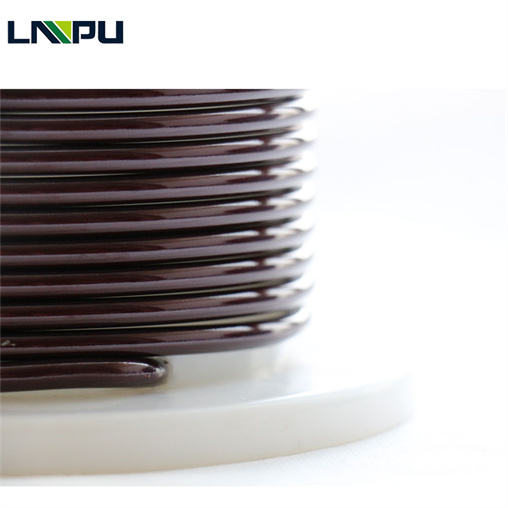

Product Name:enameled aluminum wire

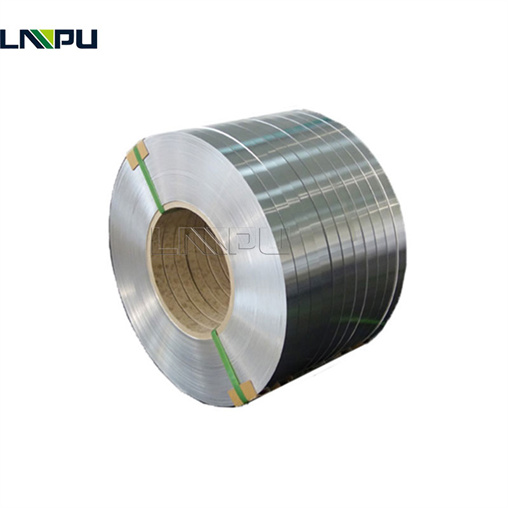

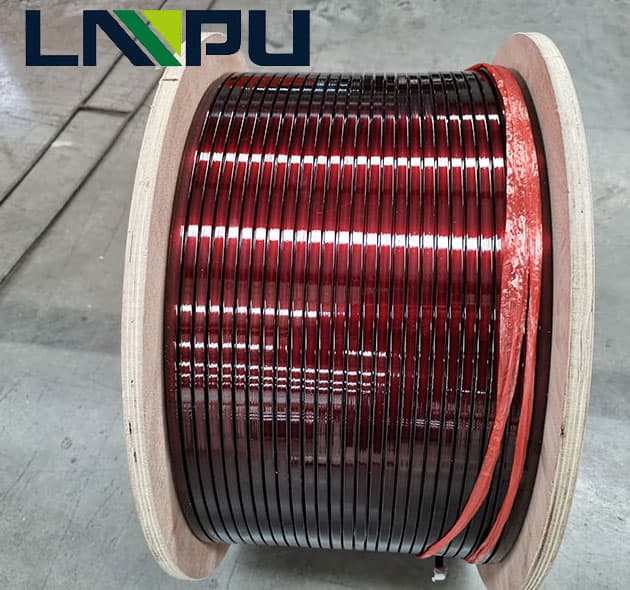

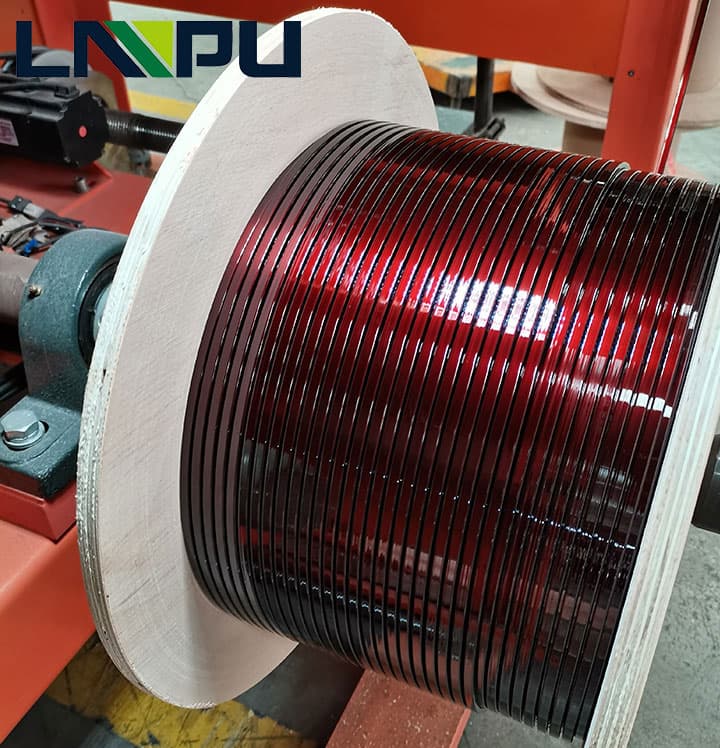

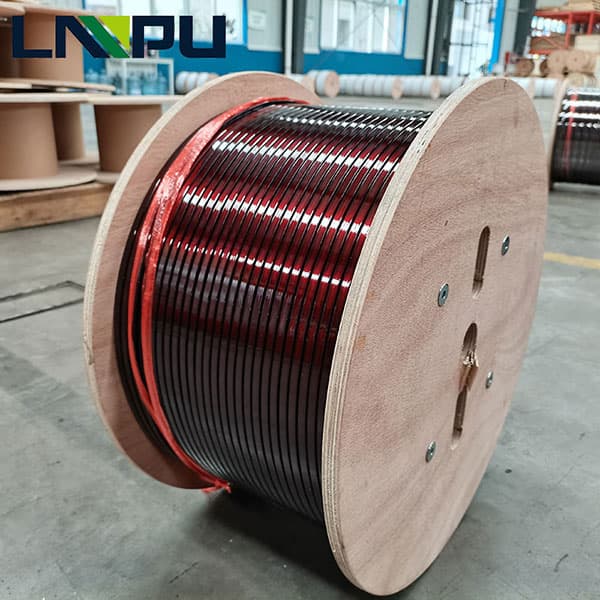

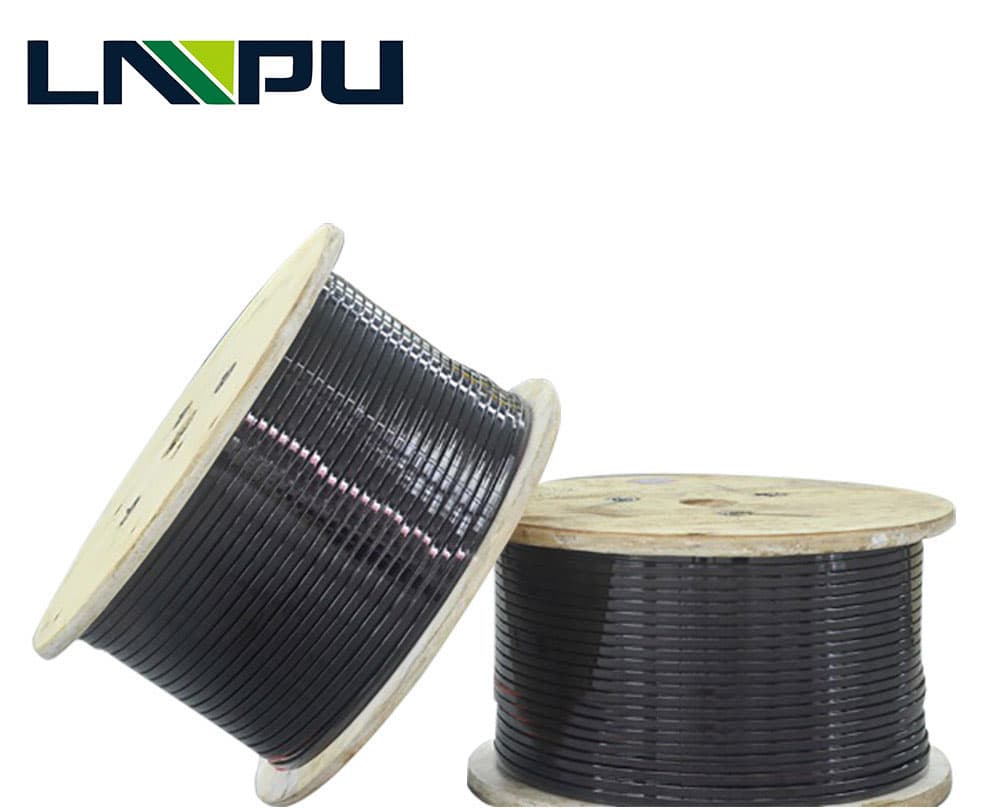

Type: flat wire

Round Dimension:A> 0.8–8mm, B> 2-22.5mm

Conductor Material:Aluminum

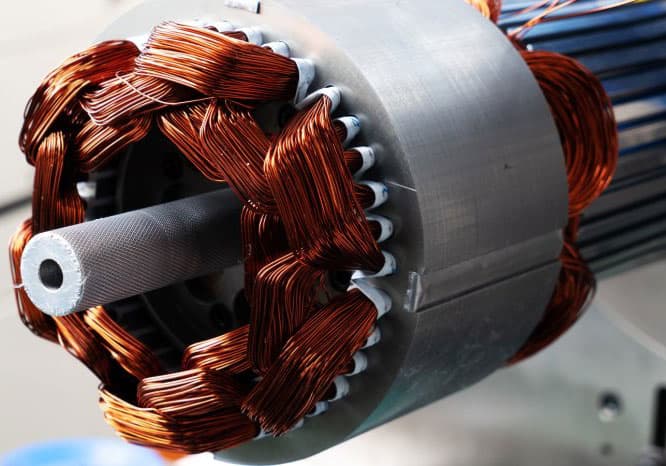

Application:used for transformers, inductors, motors, generators, dry type transformer, Cast Resin Transformers

Certificate:UL,RoHS

Insulation Materilas:UEW, QZ, QZY, EIW, etc.

Thermal Class:105¡æ, 120¡æ, 140¡æ, 155¡æ, 180¡æ, 200¡æ, 220¡æ, 240¡æ

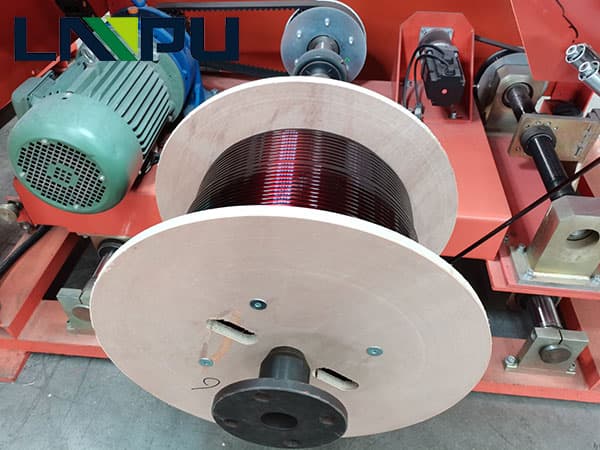

Enameled aluminum wire is a kind of enameled wire. In addition to enameled aluminum wire, there are also enameled copper wires. Enameled wire is a main type of winding wire. It consists of a conductor and an insulating layer. After the bare wire is softened by annealing, it is painted and baked many times. However, it is not easy to produce products that not only meet the requirements of the standards, but also meet the requirements of customers. It is affected by the quality of raw materials, process parameters, production equipment, environment and other factors. Therefore, the quality characteristics of various enameled wires are different, but they all have Mechanical properties, chemical properties, electrical properties, and thermal properties are four major properties. Online measurement of enameled wire can effectively control the high quality of products. However, the enameled wire runs at high speed during production. There is no way to measure accurate data with any contact measuring tool.

And it is easy to cause the line to break. Now there is a new measuring tool, laser measuring instrument, which can scan and measure by laser. The laser does not need to touch the line, and accurate data can be obtained through induction. Convenient and fast. Really monitor production in real time and monitor the whole process. If there is an abnormality, an alarm will be issued. It can also be compensated in real time by installing feedback. Make real-time corrections to the product. Achieve zero scrap. 100% qualified. The surface (appearance) of the enameled aluminum wire should be smooth, uniform in color, no particles, no oxidation, hair, yin and yang, black spots, paint stripping and other defects that affect performance. The cable should be neat, flat and tight, and wound on the wire reel. There are many factors that affect the surface without pressing the line and retracting freely, which are related to factors such as raw materials, paint, equipment, technology, and environment. Aluminum is a chemical element. Its chemical symbol is Al, and its atomic number is 13. The content of aluminum in the earth’s crust is second only to oxygen and silicon, ranking third, and it is the most abundant metal element in the earth’s crust. Among metal varieties, it is second only to steel and is the second largest category

Metal. It was not until the end of the 19th century that aluminum emerged as a competitive metal in engineering applications, and it became popular for a while. The development of the three important industries of aviation, construction, and automobiles requires the characteristics of materials to have the unique properties of aluminum and its alloys, which greatly facilitates the production and application of this new metal aluminum.

The application of aluminum is extremely wide. Aluminum is a light metal, and its density is only about one-third that of iron. Pure aluminum is silver-white. Because it is easily combined with oxygen in the air, a dense oxide film (aluminum oxide Al2O3) is formed on the surface, so it is usually slightly silver-gray. And its thin film makes aluminum not easy to be corroded. The use of a substance depends to a large extent on the nature of the substance. Because aluminum has a variety of excellent properties, aluminum has a very wide range of uses.