Home » enameled aluminum wire » High resistance metal enameled aluminum wire price

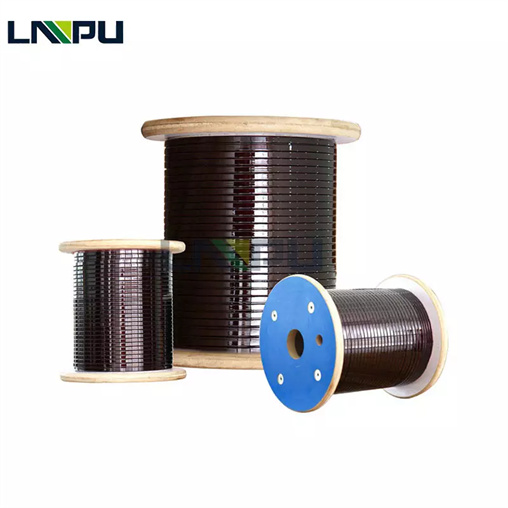

High resistance metal enameled aluminum wire price

Performance comparison of High resistance metal enameled aluminum wire:

(1) Heat resistance

(2) Resistance to solvents, chemicals and varnishes

(3) Resistance to hydrolytic degradation

(4) Stability when combined with insulating materials

(5) Resistance to water and moisture

(6) Ease of use

Contact US

Get Price

Share:

Content

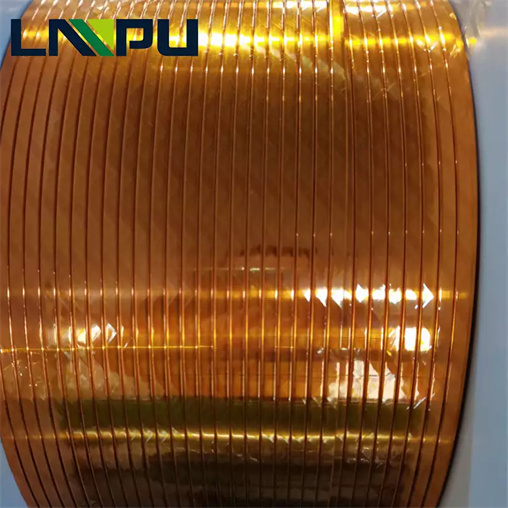

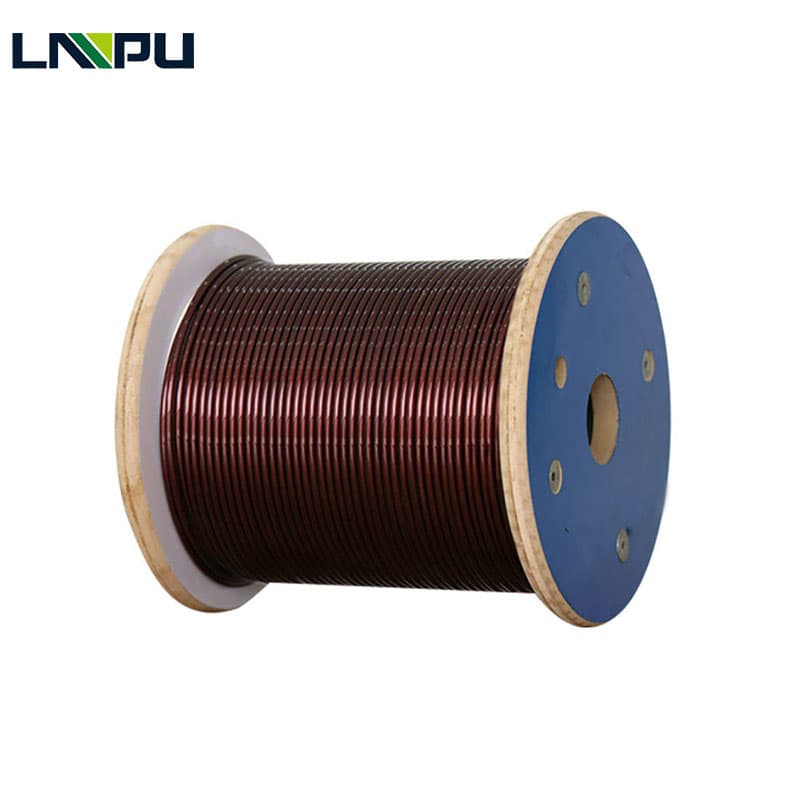

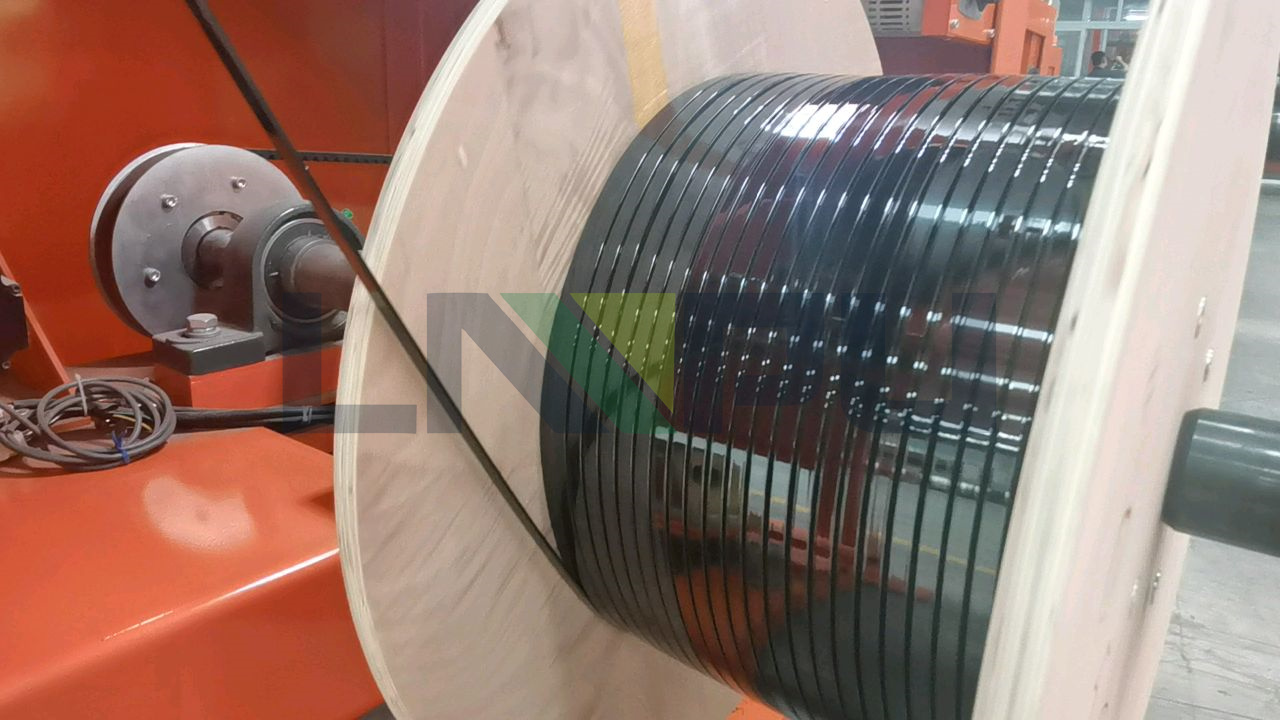

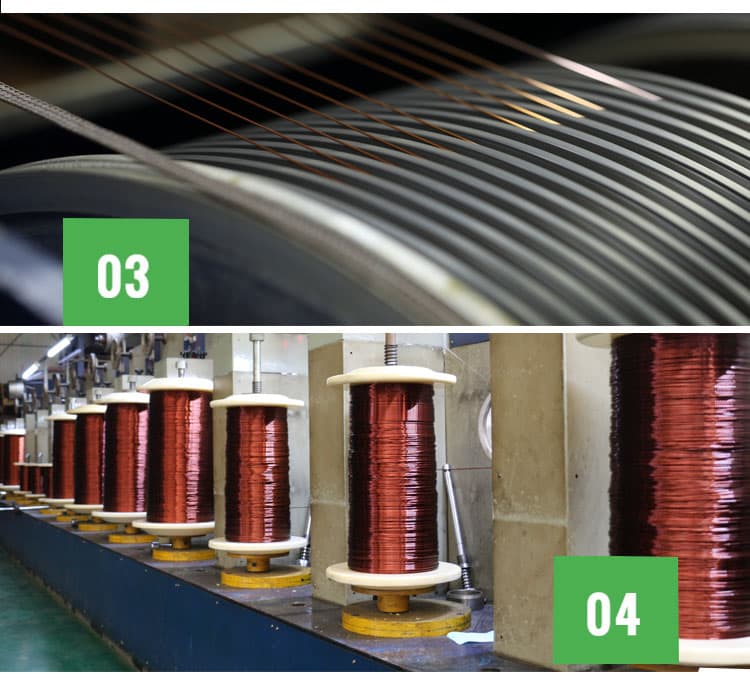

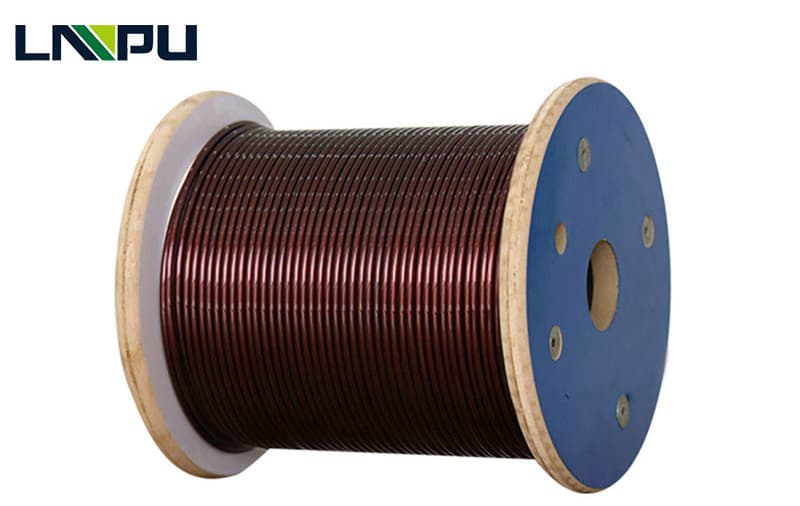

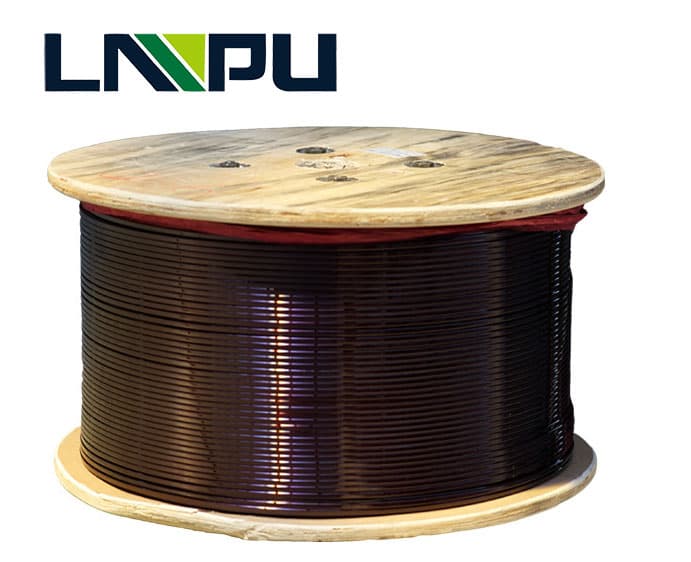

Material of enameled aluminum wire:

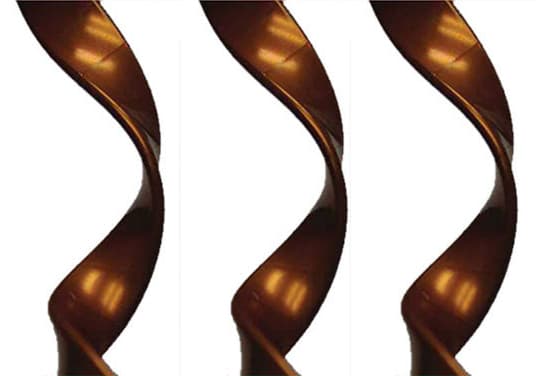

Drawing or extruding bare Aluminum magnet wire confirm to National Standard, smooth surface, no defects ;Good performance,Insulation varnish.

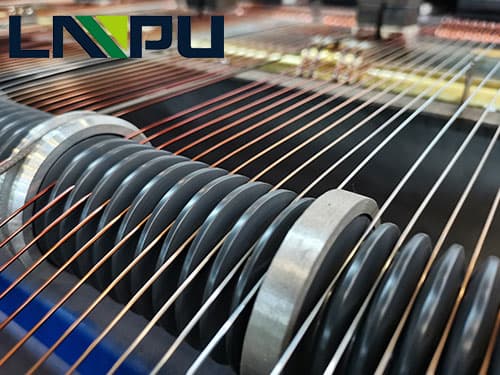

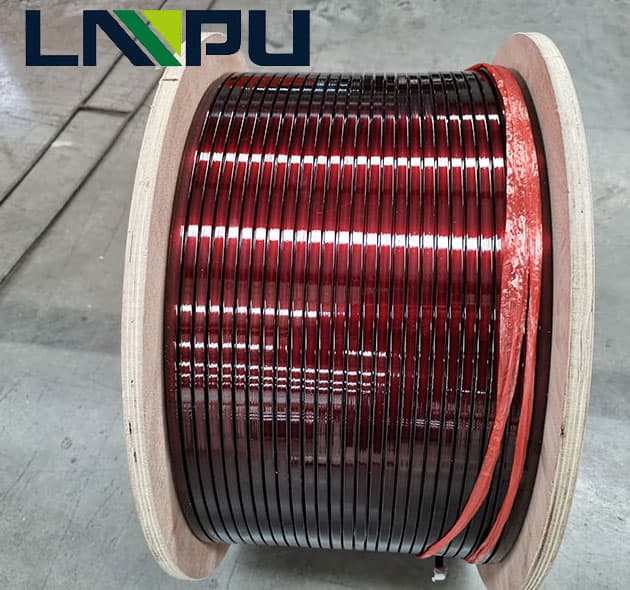

Specs of Enameled Coated Aluminum magnet wire:

| Type | Polyesterimide |

Polyimide and polyimide mixed |

Polyvinyl acetal | Thermal bonding acetal |

| Temperature-resist grade | 180 | 200 | 120(155) | 120 |

| Property |

High heat resistance, good chemical resistance, hydrolysis resistance |

Excellent heat resistance, strong resistance to chemical solvents, good scratch resistance |

Excellent resistance to transformer oil, good resistance to scratch, excellent flexibility and adhesion, and good water resistance. |

In addition to all the performance with acetal, also can obtain good adhesion strength by the heating mode |

| Standard |

GB/T7095.4-2008, IEC60317-28 |

GB/T7095.6-2008, IEC60317-29 |

GB/T7095.2-2008, IEC60317-18 |

|

|

Testing Standard |

GB/T4074, IEC60851-1-6 | |||

Inquiry

More enameled aluminum wire