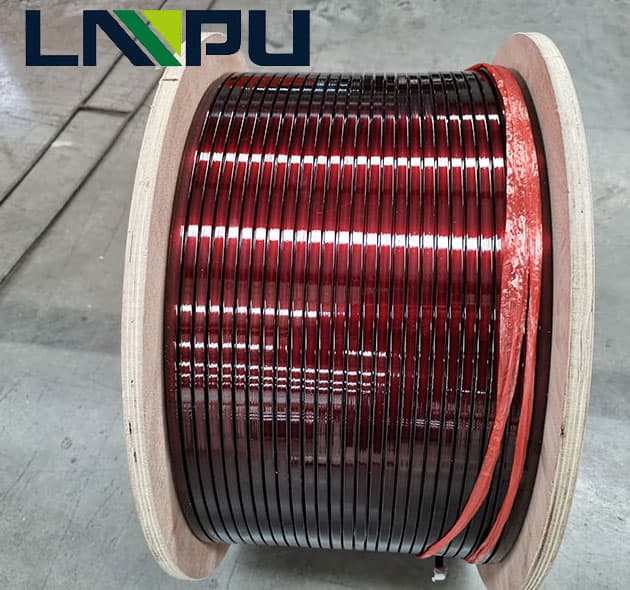

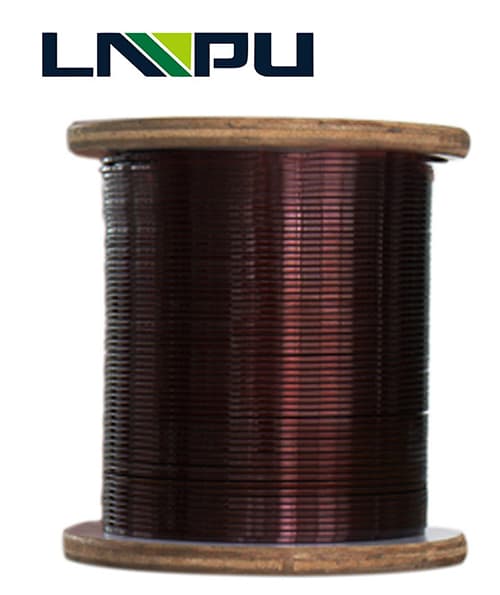

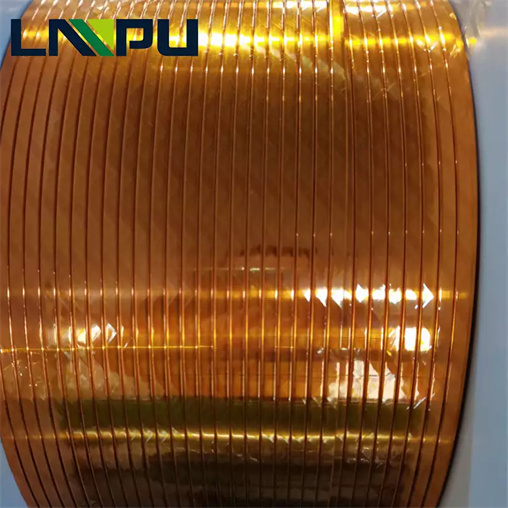

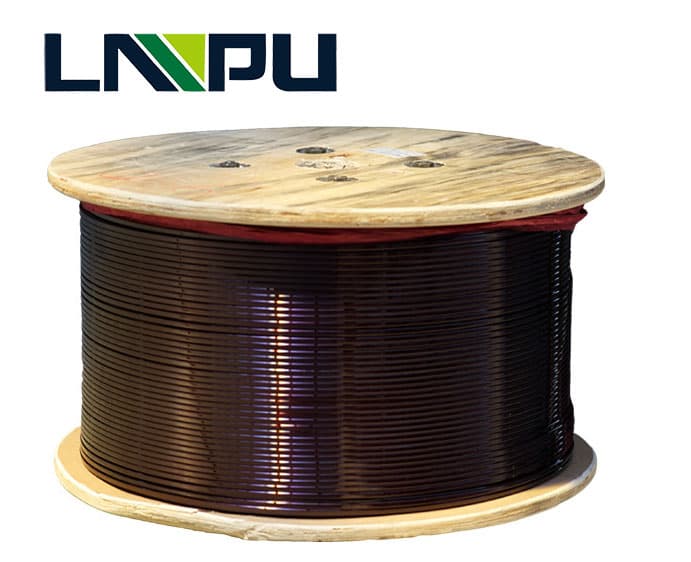

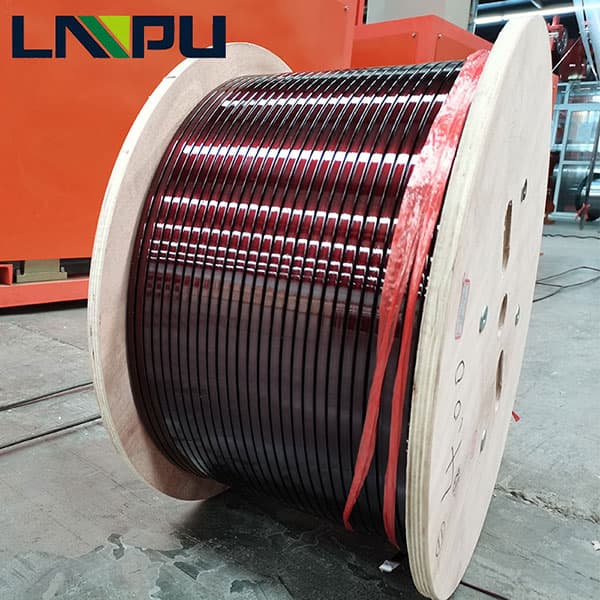

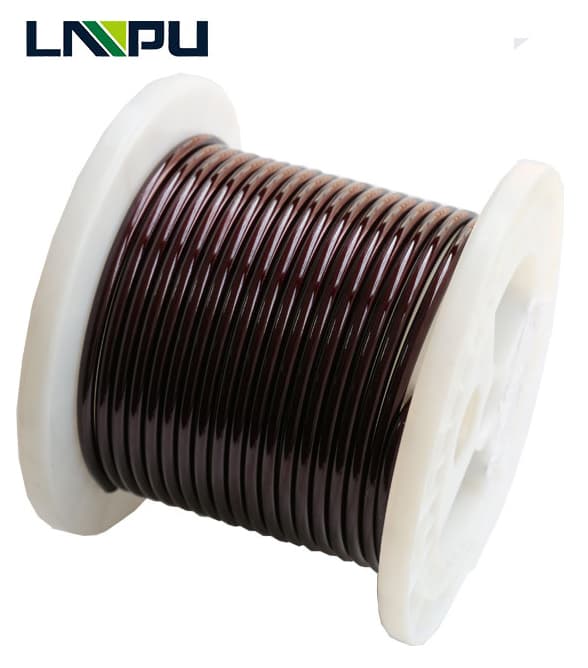

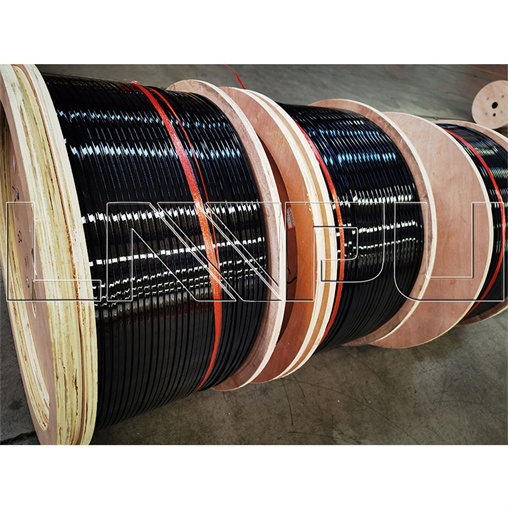

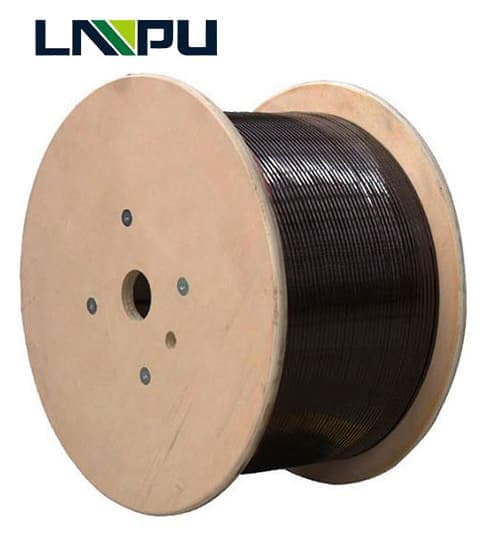

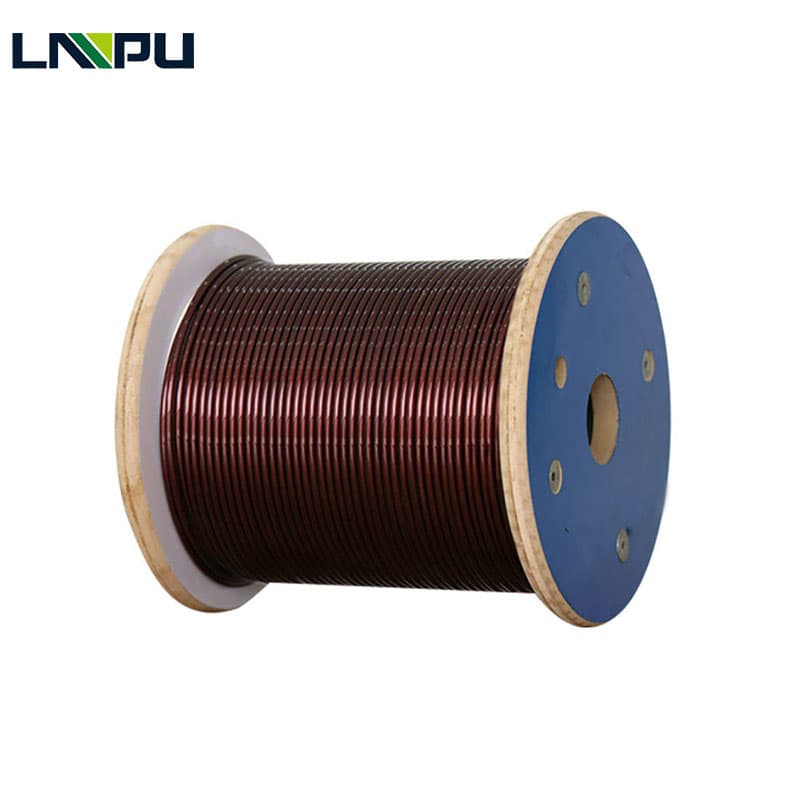

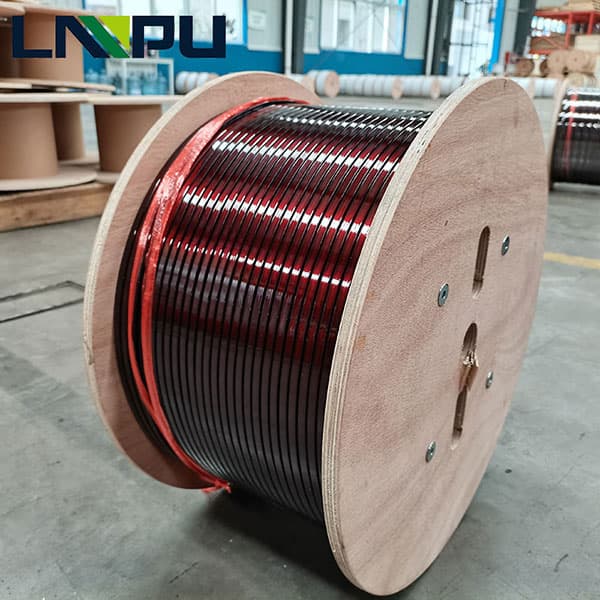

High Quality Solderable polyester-imide Aluminum Enamelled Wire

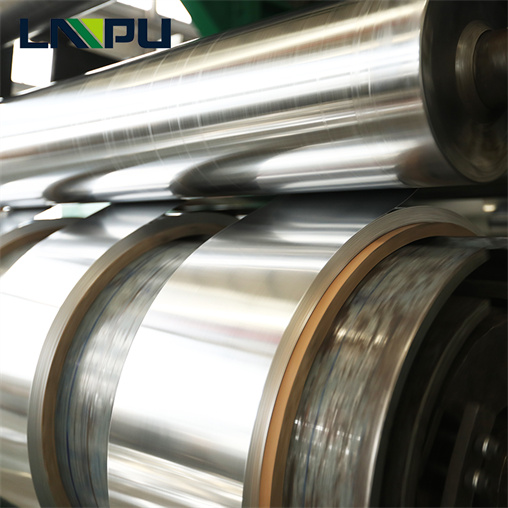

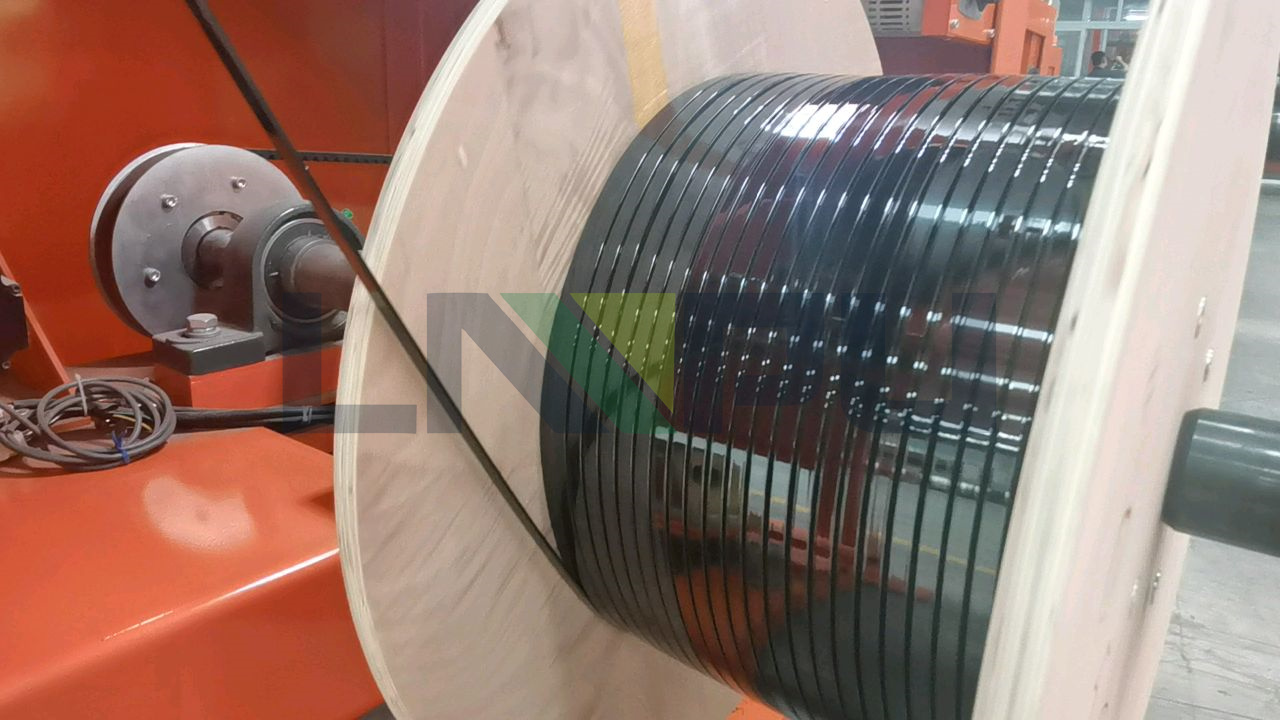

High Thermal Solderable polyester-imide Enameled Aluminum wire refers to the electrical round aluminum rod drawn by a certain specification die on the wire, according to customer requirements, with the required temperature index and compatibility insulating paint , Use mold type or felt type paint to paint multiple corresponding insulating paints. After baking treatment, the insulating paint and the wire form a whole.

Specification of High Quality Solderable polyester-imide Aluminum Enamelled Wire:

GB name: QZYH/155

Heat resistance class: H

Heat resistance temperature: 180¡ã

Specification range: 0.10-1.2mm

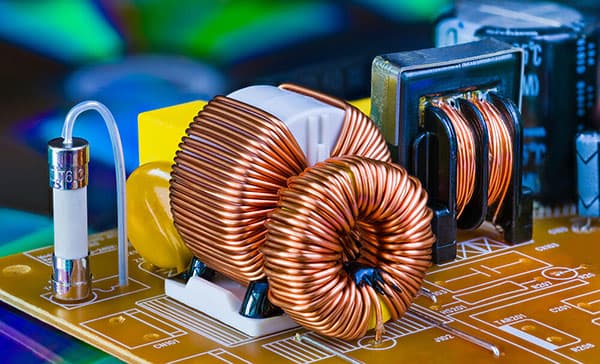

Main application of High Quality Solderable polyester-imide Aluminum Enamelled Wire

High Thermal Solderable polyester-imide Enameled Aluminum wire is used for special-purpose equipment. It has excellent heat resistance and can be directly welded at 455¡ãC.