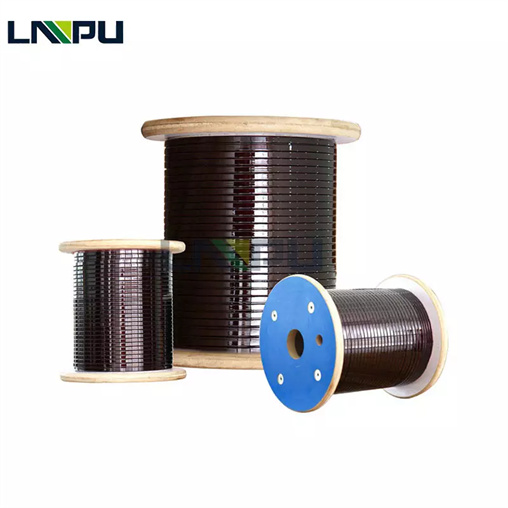

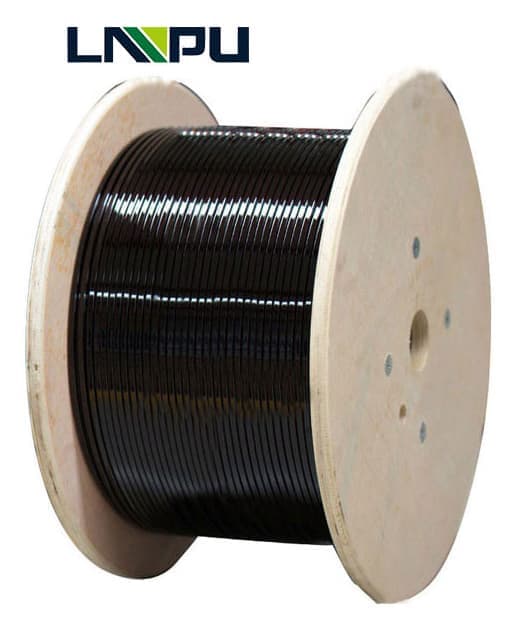

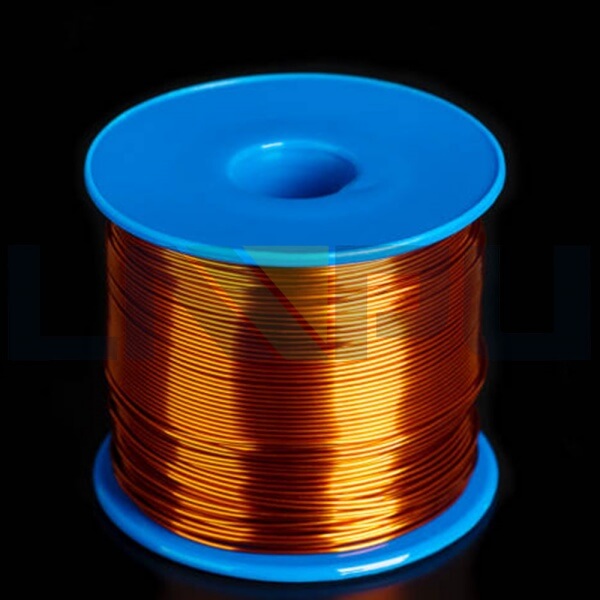

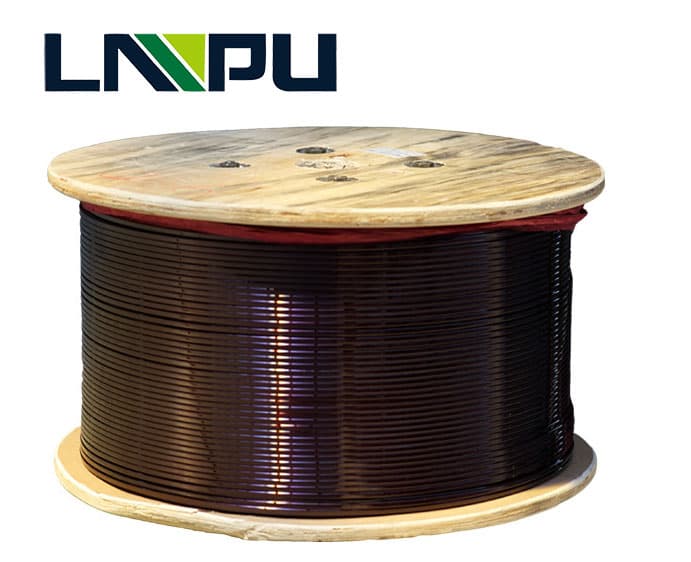

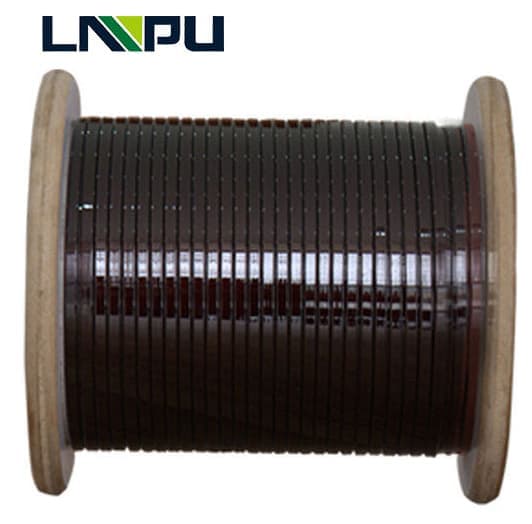

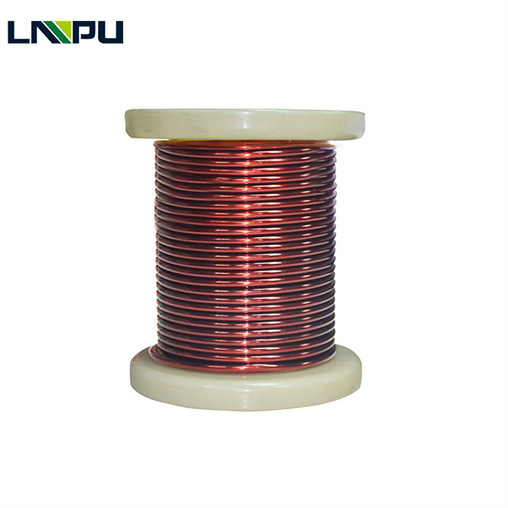

High Heat Resistance 42 Awg Magnet Aluminum Wire

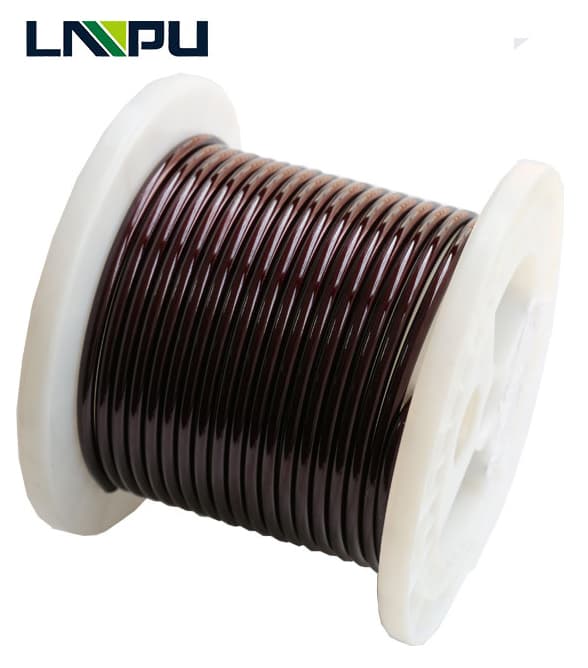

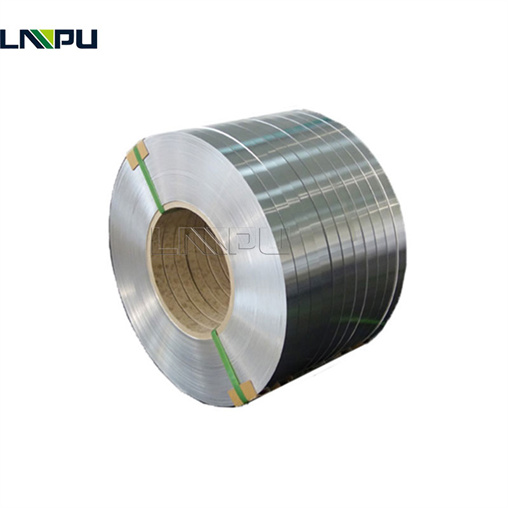

The advantage of High Heat Resistance 42 Awg Magnet Aluminum Wire is its light weight. This product is widely used in power tools, ballasts, automotive electronics, refrigerator and air-conditioning compressor motors, televisions, electric stoves, microwave ovens, various transformers and other various electronic coil motors and appliances.

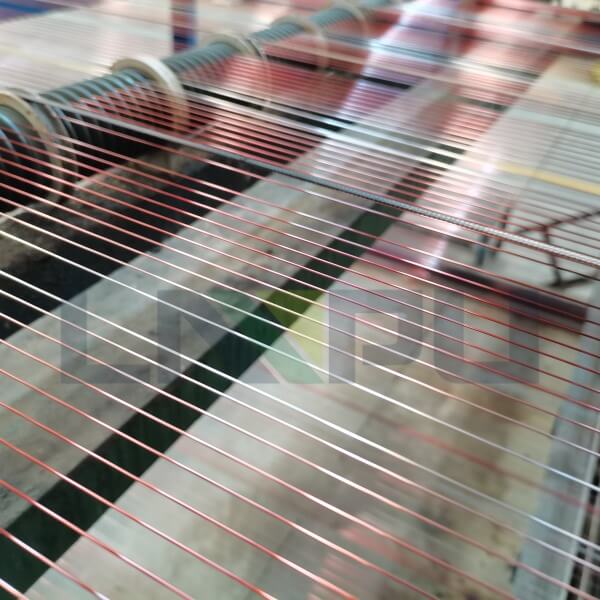

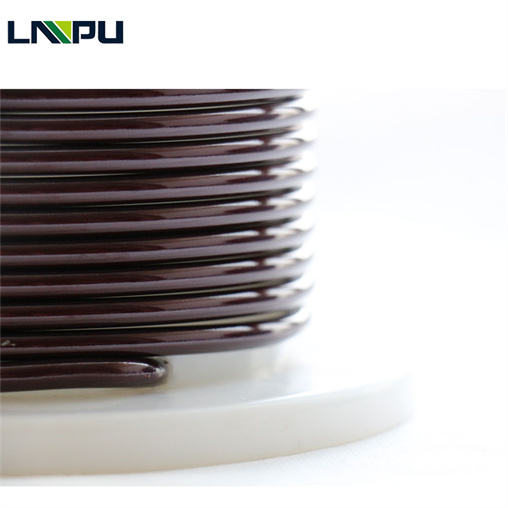

The mechanical, electrical and chemical properties of enameled aluminum magnet wires are different from those of copper magnet wires because of inherent differences in conductor materials. These differences are reflected in certain test procedures and/or performance requirements of aluminum magnet wire, such as elongation, adhesion and flexibility, thermal shock, scratch resistance, continuity and heat resistance.